Professional Surface Mount Electronic Components: The Backbone of Modern Electronics

Introduction

In the rapidly evolving landscape of electronics manufacturing, Professional Surface Mount Electronic Components have emerged as the fundamental building blocks powering technological innovation across industries. These sophisticated components represent a monumental shift from traditional through-hole technology, enabling the creation of smaller, faster, and more efficient electronic devices that define our modern world. From smartphones and medical devices to automotive systems and industrial equipment, surface mount technology (SMT) has revolutionized how we design, manufacture, and implement electronic solutions. The precision engineering behind these components allows for unprecedented levels of miniaturization while maintaining exceptional performance and reliability standards. As technology continues to advance at an accelerated pace, understanding the critical role of professional-grade surface mount components becomes increasingly vital for engineers, designers, and procurement specialists who strive to stay competitive in the global marketplace. This comprehensive exploration delves into the essential aspects of these components, their advantages, selection criteria, and future trajectory, providing valuable insights for professionals navigating the complex world of electronic component sourcing and implementation.

The Evolution and Advantages of Surface Mount Technology

Historical Context and Technological Progression

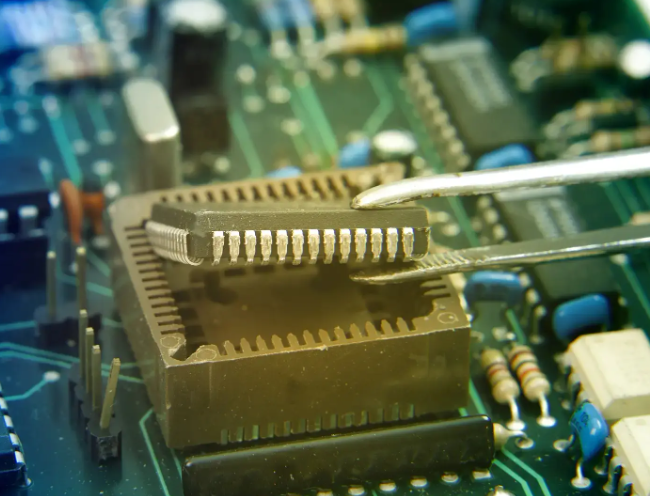

The development of surface mount technology represents one of the most significant transformations in electronics manufacturing history. Before SMT became mainstream in the 1980s, through-hole technology dominated circuit board assembly, requiring components with wire leads that passed through holes in the printed circuit board (PCB). This method, while reliable, imposed significant limitations on miniaturization, manufacturing speed, and design flexibility. The transition to surface mounting began as electronic devices became more complex and consumer demand for compact products intensified. The aerospace and military sectors were among the early adopters of SMT due to their need for high reliability in compact form factors, paving the way for widespread commercial adoption.

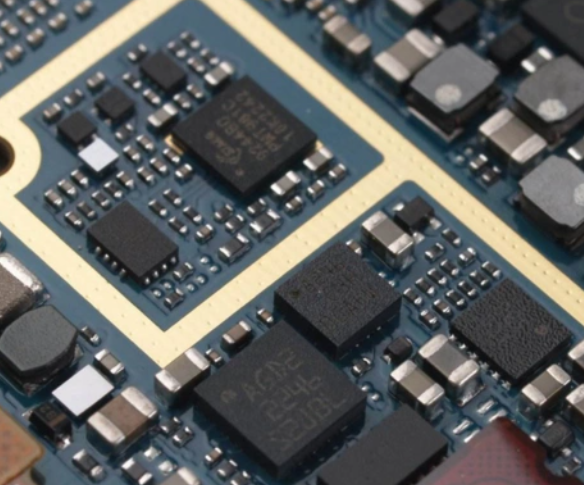

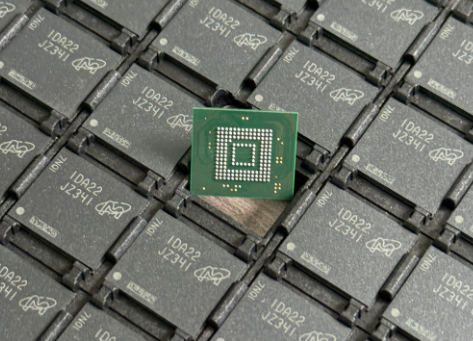

The evolution of SMT has been characterized by continuous refinement in materials, manufacturing processes, and component design. Early surface mount components were relatively large by today’s standards, but ongoing innovation has led to increasingly miniature packages while improving electrical characteristics and thermal performance. The progression from SOIC packages to QFPs, BGAs, and eventually to chip-scale packages and 01005 components demonstrates the relentless pursuit of miniaturization without compromising functionality. This technological journey has been supported by parallel advancements in PCB fabrication, solder paste formulations, pick-and-place machinery, and reflow soldering techniques, creating a sophisticated ecosystem that enables mass production of highly complex electronic assemblies.

Key Advantages Driving Widespread Adoption

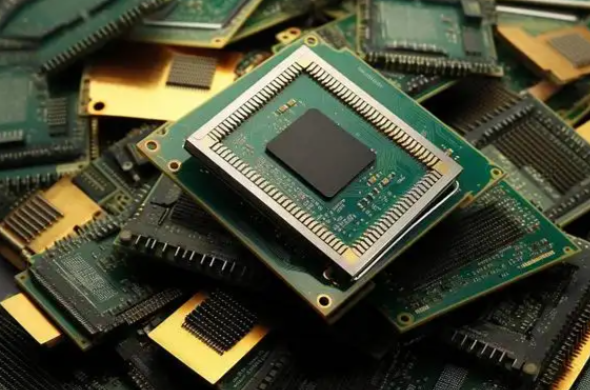

Professional Surface Mount Electronic Components offer numerous compelling advantages that explain their dominance in contemporary electronics manufacturing. The most significant benefit is the dramatic reduction in size and weight compared to through-hole counterparts. Surface mount devices (SMDs) can be up to 70% smaller while providing equivalent or superior functionality, enabling the sleek, portable devices that consumers expect today. This miniaturization directly translates to higher component density on PCBs, allowing for more features in less space or creating opportunities for entirely new product categories that wouldn’t be feasible with older technologies.

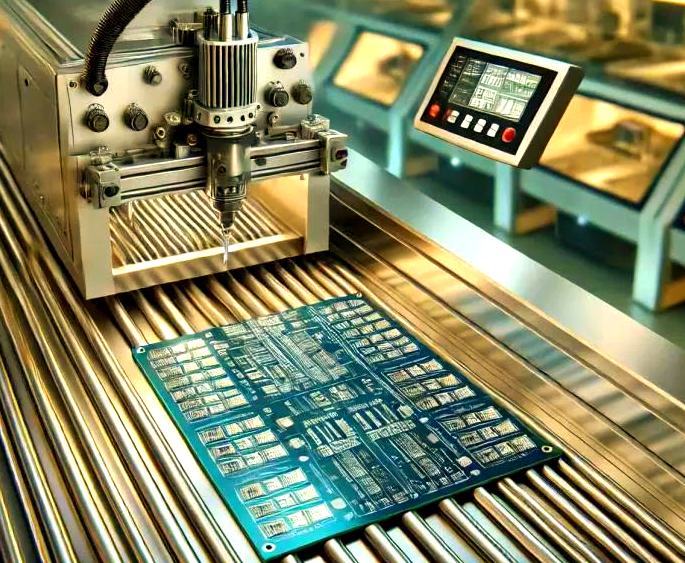

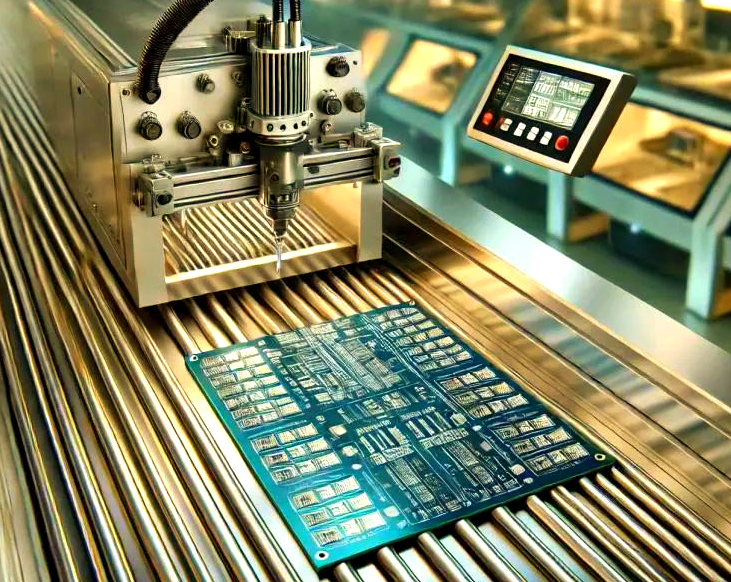

Beyond physical dimensions, SMT delivers substantial improvements in manufacturing efficiency and performance characteristics. Surface mount assembly enables higher levels of automation, with modern pick-and-place machines capable of positioning tens of thousands of components per hour with exceptional accuracy. This automation reduces labor costs, improves consistency, and increases production throughput. From an electrical perspective, SMDs typically offer better high-frequency performance due to reduced lead inductance and capacitance. The shorter electrical paths contribute to enhanced signal integrity at high speeds, a critical consideration in modern communications equipment computing devices. Additionally, the manufacturing process itself is more streamlined, as SMT eliminates the drilling step required for through-hole components and allows for double-sided assembly, further optimizing board space utilization.

Critical Considerations in Component Selection and Sourcing

Technical Parameters and Performance Specifications

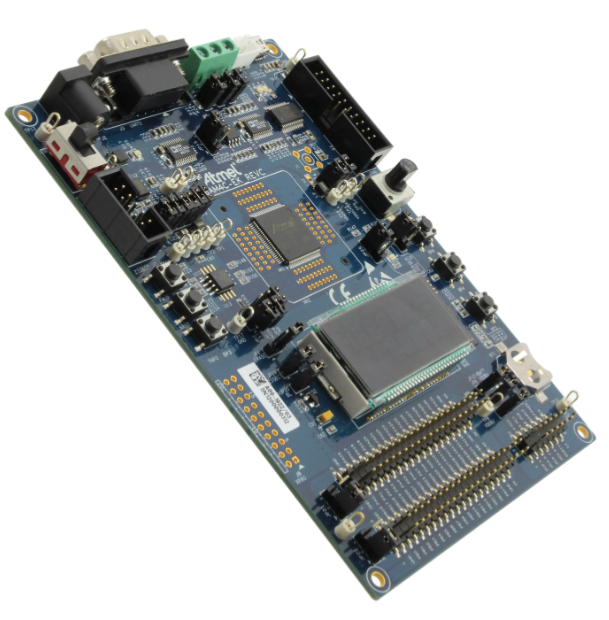

Selecting the appropriate Professional Surface Mount Electronic Components requires careful evaluation of numerous technical parameters to ensure optimal performance in the target application. Electrical characteristics form the foundation of component selection, including voltage ratings current handling capabilities frequency response tolerance values temperature coefficients. For passive components like resistors capacitors these specifications determine how the component will behave under various operating conditions active components such as integrated circuits transistors additional considerations include switching speeds power dissipation package thermal characteristics become critically important.

The physical attributes of surface mount components demand equal attention during the selection process. Package dimensions mounting configurations directly impact manufacturability final product size advanced packaging options like ball grid arrays (BGAs) quad flat no-lead (QFN) packages offer space savings enhanced electrical performance but may present challenges regarding inspection rework Component terminal types solder joint reliability under mechanical thermal stress must align with the product’s operational environment expected lifespan For applications subjected to harsh conditions automotive industrial sectors components with appropriate certifications operating temperature ranges become essential selection criteria.

Supply Chain Considerations Sourcing Strategies

In today’s global electronics marketplace effective sourcing Professional Surface Mount Electronic Components requires sophisticated supply chain management strategies beyond simple price comparisons The semiconductor shortage highlighted vulnerabilities traditional just-in-time inventory approaches prompting organizations develop more resilient multifaceted sourcing frameworks Establishing relationships authorized distributors reputable suppliers like ICGOODFIND provides access genuine components technical support reducing counterfeit risks ensuring consistent quality.

Strategic sourcing involves balancing multiple factors including cost availability logistical considerations ICGOODFIND emerges valuable resource professionals seeking reliable component sources offering comprehensive inventory management solutions market intelligence The platform facilitates informed decision-making through detailed component information cross-referencing alternative parts market pricing trends Beyond transactional relationships successful organizations cultivate partnerships suppliers distributors enhance visibility potential disruptions implement risk mitigation strategies such as strategic stocking long-term agreements multiple sourcing options for critical components.

Implementation Best Practices Future Trends

Design Manufacturing Considerations

Successfully implementing Professional Surface Mount Electronic Components requires meticulous attention design manufacturing details maximize performance reliability PCB layout considerations significantly impact final product quality including pad design component orientation trace routing thermal management strategies Proper land pattern design ensures reliable solder joints prevents issues tombstoning solder bridging while thoughtful component placement facilitates efficient assembly processes simplifies rework when necessary.

Thermal management represents particularly critical consideration modern electronics designs High component density increased power densities necessitate proactive thermal planning incorporating appropriate thermal vias heat sinks thermal pads where necessary different component packages exhibit varying thermal characteristics understanding these properties essential creating designs withstand operational thermal stresses over product lifetime manufacturing process itself requires careful control numerous parameters including solder paste application placement accuracy reflow profile optimization achieve consistent high-quality results.

Emerging Trends Future Directions

The landscape Professional Surface Mount Electronic Components continues evolve rapidly response technological advancement market demands Miniaturization remains driving force component development with manufacturers pushing boundaries package sizes while maintaining improving electrical performance Emerging package technologies such system-in-package (SiP) wafer-level packaging (WLP) enable higher levels integration reducing overall footprint while enhancing functionality between components.

Beyond miniaturization several key trends shaping future surface mount components Increased integration smart functionality becoming standard across component categories with embedded sensors processing capabilities communication interfaces becoming commonplace passive active components Environmental sustainability gaining prominence driving development halogen-free materials recyclable packaging energy-efficient manufacturing processes Additionally specialized components designed specific applications automotive medical aerospace expanding offering tailored solutions extreme reliability requirements harsh operating conditions.

Conclusion

Professional Surface Mount Electronic Components represent cornerstone modern electronics enabling technological advancements across virtually every sector of global economy The transition from through-hole technology surface mounting has facilitated development smaller more powerful efficient electronic devices that have transformed how we live work communicate As technology continues advance the importance high-quality properly specified surface mount components will only increase requiring professionals deepen their understanding selection criteria implementation best practices emerging trends.

The complexity of contemporary electronic systems demands careful consideration numerous factors when selecting sourcing surface mount components from basic electrical parameters physical characteristics broader supply chain implications platforms like ICGOODFIND provide valuable resources navigating this complex landscape helping professionals identify reliable sources genuine components technical information By staying informed about latest developments maintaining strategic approach component selection sourcing design manufacturing organizations can position themselves success increasingly competitive demanding marketplace The future surface mount technology promises continued innovation miniaturization integration creating exciting opportunities those prepared leverage these advancements their products systems.