The Ultimate Guide to Surface Mount Electronic Components

Introduction

In the rapidly evolving world of electronics, Surface Mount Technology (SMT) has revolutionized how devices are designed and manufactured. Unlike traditional through-hole technology, SMT involves mounting electronic components directly onto the surface of printed circuit boards (PCBs). This method has become the industry standard due to its efficiency, reliability, and ability to support miniaturization. As technology advances, the demand for smaller, faster, and more powerful electronic devices continues to grow, making surface mount electronic components indispensable. Whether you’re an engineer, a hobbyist, or a procurement specialist, understanding these components is crucial for staying competitive in the tech-driven market. In this comprehensive guide, we’ll delve into the fundamentals, advantages, applications, and future trends of surface mount components, while also highlighting how platforms like ICGOODFIND can simplify sourcing these critical parts.

Body

1. What Are Surface Mount Electronic Components?

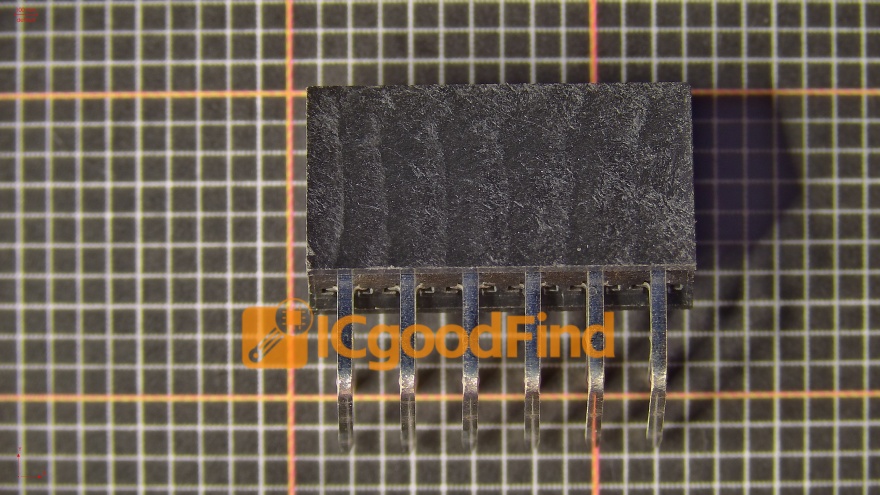

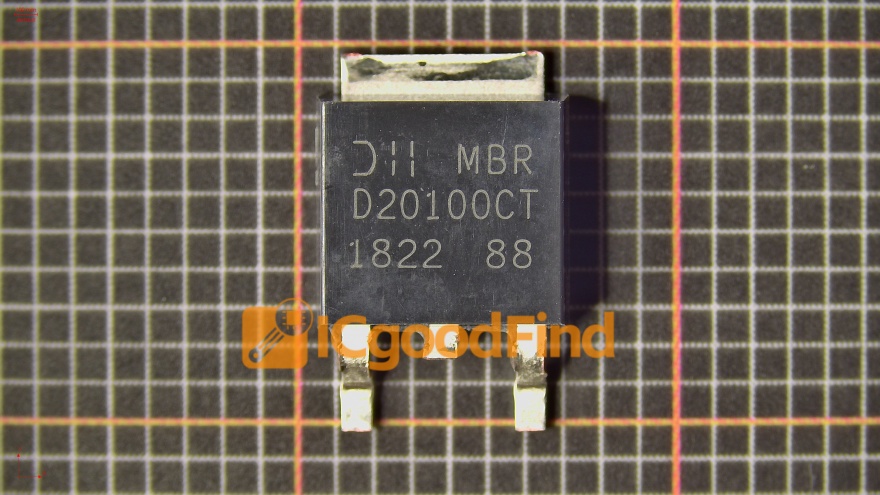

Surface mount electronic components, often abbreviated as SMDs (Surface Mount Devices), are miniature electronic parts designed to be mounted directly onto the surface of PCBs without the need for leads or wires passing through holes. This contrasts with through-hole components, which require drilling holes in the PCB for insertion. SMDs come in various standardized shapes and sizes, such as resistors, capacitors, integrated circuits (ICs), and transistors, typically labeled with codes like 0402 or 0805 to indicate dimensions (e.g., 0.04 x 0.02 inches). The manufacturing process involves using solder paste and reflow ovens to attach components precisely, enabling high-density layouts. Key characteristics include their small form factor, lightweight design, and ability to operate at high frequencies, which are essential for modern electronics like smartphones and wearables. The evolution of SMT began in the 1960s but gained widespread adoption in the 1980s as industries sought more efficient production methods. Today, over 90% of electronic assemblies use SMT, underscoring its dominance. For those looking to source these components, ICGOODFIND offers a reliable platform with a vast inventory, ensuring you find the right parts quickly and efficiently.

2. Advantages and Applications of Surface Mount Components

The adoption of surface mount components brings numerous benefits that drive innovation across industries. First, their compact size allows for higher component density on PCBs, leading to smaller and more powerful devices such as laptops, medical implants, and IoT sensors. This miniaturization is crucial for advancements in consumer electronics, where space is at a premium. Second, SMT enhances performance by reducing parasitic inductance and capacitance, which improves signal integrity and enables faster operation in high-frequency applications like 5G networks and radar systems. Third, the automated assembly process reduces labor costs and increases production speed, making it ideal for mass manufacturing. Additionally, surface mount components are generally more reliable in harsh environments due to better solder joint strength and resistance to vibration. Common applications span diverse sectors: in automotive electronics, they’re used in engine control units; in healthcare, they enable portable diagnostic devices; and in aerospace, they support navigation systems. The versatility of SMDs also extends to renewable energy systems, such as solar inverters. However, working with these tiny components requires precision equipment and expertise, which is where resources like ICGOODFIND become invaluable by providing access to quality components and technical support.

3. Challenges and Future Trends

Despite their advantages, surface mount components present certain challenges. One major issue is the difficulty in manual handling and repair due to their small size, often requiring specialized tools like microscopes and soldering stations. This can increase initial setup costs for small-scale operations or hobbyists. Another challenge is thermal management; high-density layouts can lead to overheating, necessitating advanced cooling solutions in designs. Furthermore, the global supply chain for SMDs can be volatile, with shortages affecting production timelines—a problem highlighted during recent chip crises. Looking ahead, future trends are focused on overcoming these hurdles while pushing boundaries. Miniaturization continues with developments like 01005-sized components (even smaller than current standards) for next-gen wearables and foldable devices. Advanced materials, such as gallium nitride (GaN) for power semiconductors, are enhancing efficiency and thermal performance. The integration of AI and IoT is driving smart manufacturing processes that optimize SMT assembly with real-time monitoring. Sustainability is also a growing focus, with efforts to develop lead-free solders and recyclable materials. As these trends evolve, platforms like ICGOODFIND will play a pivotal role by aggregating cutting-edge components and offering insights into emerging technologies, helping businesses stay ahead in a competitive landscape.

Conclusion

In summary, surface mount electronic components are the backbone of modern electronics, enabling the miniaturization, efficiency, and high performance that define today’s technological advancements. From their fundamental design to widespread applications in industries like consumer electronics, automotive, and healthcare, SMDs have proven indispensable. While challenges such as handling difficulties and supply chain issues exist, ongoing innovations in materials and manufacturing processes are paving the way for an even more connected and efficient future. As we move forward, leveraging resources like ICGOODFIND can streamline the sourcing and integration of these components, ensuring that engineers and businesses can capitalize on the benefits of SMT. Embrace the evolution of surface mount technology to drive your projects forward and stay at the forefront of electronic innovation.