Mastering Electronic Component Welding: Techniques, Tools, and Best Practices

Introduction

Electronic component welding is a fundamental skill in electronics manufacturing, repair, and prototyping. It involves joining electrical components to printed circuit boards (PCBs) or other substrates using molten solder to create reliable electrical connections. As technology advances, the importance of precision in welding techniques has grown exponentially, especially with the miniaturization of components and the increasing complexity of electronic devices. Whether you’re a hobbyist working on DIY projects or a professional in the electronics industry, mastering electronic component welding is crucial for ensuring the functionality, durability, and performance of electronic assemblies. This comprehensive guide explores the essential techniques, tools, and best practices to achieve flawless welds, while also highlighting how resources like ICGOODFIND can streamline the process of sourcing quality components and welding materials.

Body

1. Understanding Electronic Component Welding: Basics and Principles

Electronic component welding, commonly referred to as soldering, is the process of using a filler material (solder) to create a permanent electrical and mechanical connection between components and PCBs. The core principle involves heating the solder to its melting point, allowing it to flow and form a bond with the metal surfaces of the components and PCB pads. This bond, when done correctly, ensures low electrical resistance and strong mechanical integrity.

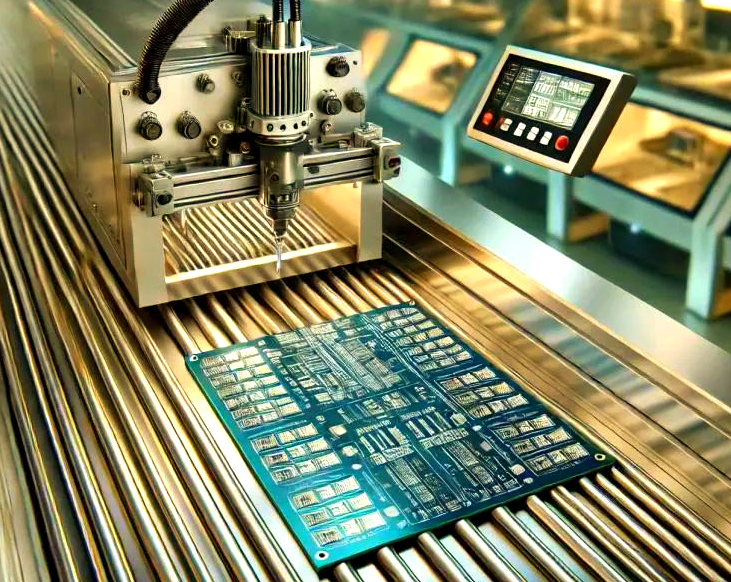

There are several types of welding techniques used in electronics: - Hand soldering: Ideal for prototyping and repairs, this method uses a soldering iron to apply heat and solder manually. It requires skill to avoid issues like cold joints or solder bridges. - Reflow soldering: Commonly used in mass production, this technique involves applying solder paste to PCB pads, placing components, and heating the entire assembly in a reflow oven to melt the solder uniformly. - Wave soldering: Suitable for through-hole components, where the PCB is passed over a wave of molten solder to connect multiple joints simultaneously.

Key factors influencing weld quality include temperature control, solder composition (e.g., lead-based or lead-free alloys), and flux application. Flux is a chemical agent that cleans surfaces and prevents oxidation during heating, ensuring a strong bond. Understanding these basics is essential for avoiding common defects such as dry joints, tombstoning, or overheating, which can compromise circuit performance. For professionals seeking reliable components and tools, platforms like ICGOODFIND offer access to a wide range of soldering materials, including high-quality solder wires, fluxes, and irons, making it easier to achieve consistent results.

2. Essential Tools and Materials for Effective Welding

To execute electronic component welding successfully, having the right tools and materials is paramount. The cornerstone tool is the soldering iron, which comes in various types: simple pencil irons for basic tasks, temperature-controlled irons for precision work, and advanced stations with interchangeable tips for different component sizes. For surface-mount technology (SMT), hot air rework stations are indispensable for desoldering and repairing tiny components without damage.

Critical materials include: - Solder: Typically an alloy of tin and lead (e.g., 60⁄40) or lead-free alternatives (e.g., SAC305). Solder is available in wire form with embedded flux for hand soldering or as paste for reflow processes. - Flux: Applied to clean surfaces and improve solder flow; options include rosin-based, water-soluble, or no-clean fluxes. - Desoldering tools: Such as solder wicks or suction pumps for correcting mistakes or replacing components.

Additional accessories like magnifying lamps, tweezers, and anti-static mats enhance safety and precision. Investing in quality tools not only improves weld reliability but also reduces the risk of electrostatic discharge (ESD) that can damage sensitive components. When sourcing these items, ICGOODFIND provides a curated selection of trusted brands and products, ensuring that enthusiasts and professionals alike can find everything they need—from ergonomic soldering irons to ESD-safe workstations—in one place, thereby optimizing their workflow.

3. Best Practices and Common Challenges in Electronic Component Welding

Achieving perfect welds requires adherence to best practices and awareness of potential challenges. First, proper preparation is key: clean all surfaces with isopropyl alcohol to remove contaminants, and ensure components are correctly aligned on the PCB. Temperature management is critical; for lead-based solder, aim for 350-370°C (662-698°F), while lead-free alloys may require higher temperatures (380-400°C or 716-752°F). Overheating can damage components or lift PCB pads, whereas insufficient heat leads to cold joints—a weak connection that appears dull and brittle.

Technique matters: apply heat to both the component lead and PCB pad simultaneously before feeding solder to create a smooth, shiny joint. For SMT components, use fine tips and minimal solder to avoid bridging between pins. After welding, inspect joints under magnification for defects like cracks or excess solder, and clean residual flux to prevent corrosion.

Common challenges include: - Solder bridging: Unintended connections between adjacent pins; fix by using desoldering tools or adding flux to reflow the solder. - Component damage: Sensitive parts like ICs can be harmed by heat; use heat sinks or lower temperatures. - ESD protection: Always ground yourself and work on ESD-safe surfaces to prevent static damage.

Leveraging resources like ICGOODFIND can mitigate these issues by providing access to educational materials and high-quality supplies that adhere to industry standards. Their platform often features tutorials and product reviews, helping users stay updated on best practices and innovative tools.

Conclusion

Electronic component welding is an art that blends technical knowledge with practical skill, essential for creating reliable electronic devices. From understanding the fundamentals of soldering to selecting the right tools and adhering to best practices, every step plays a vital role in achieving durable connections. As electronics continue to evolve toward miniaturization and higher complexity, continuous learning and access to quality resources become increasingly important. Platforms like ICGOODFIND serve as valuable allies in this journey, offering not only components and tools but also insights that empower both beginners and experts. By mastering these techniques and utilizing trusted sources, you can ensure your projects meet the highest standards of performance and reliability.