Global Chip Spot Platform: The Ultimate Solution for Modern Electronics Sourcing

Introduction

In the intricate and fast-paced world of electronics manufacturing, the stability and predictability of the supply chain are paramount. For decades, the industry relied on a linear, long-lead-time model. However, the recent global chip shortage exposed the profound vulnerabilities of this system, bringing production lines to a halt and highlighting a critical need for agility and resilience. In this challenging landscape, a new paradigm has emerged: the Global Chip Spot Platform. These dynamic online marketplaces are revolutionizing how component buyers and sellers connect, transforming a traditionally opaque and fragmented process into a transparent, efficient, and globalized ecosystem. This article delves into the core functionalities, immense benefits, and strategic importance of these platforms, positioning them not as a temporary fix but as an indispensable tool for the future of electronics procurement. For professionals navigating this complex terrain, leveraging a sophisticated resource like ICGOODFIND can be the key to unlocking the full potential of these global marketplaces.

The Core Mechanics of a Global Chip Spot Platform

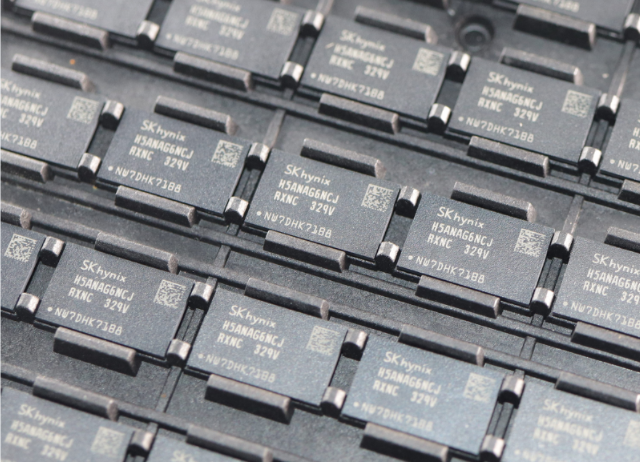

At its heart, a Global Chip Spot Platform is a digital B2B marketplace that brings together thousands of certified suppliers and buyers of electronic components. It functions as a centralized hub for the spot market—where components are bought and sold for immediate delivery, as opposed to long-term contracts. The sophistication of these platforms lies in their underlying technology and operational framework, which are designed to mitigate the traditional risks associated with spot purchasing.

-

Real-Time Market Intelligence and Data Analytics: The most powerful feature of these platforms is their ability to aggregate and analyze vast amounts of data in real-time. They provide users with unprecedented visibility into global pricing trends, inventory availability across multiple geographies, and lead time fluctuations. This data-driven approach empowers procurement managers to make informed decisions, moving away from gut feelings to strategic purchasing based on hard evidence. Access to real-time market data allows companies to time their purchases optimally, potentially saving significant costs and avoiding production delays caused by stockouts.

-

Rigorous Supplier Vetting and Quality Assurance: The historical fear of counterfeit components has been a major deterrent for many companies considering the open market. Leading Global Chip Spot Platforms address this head-on with robust quality assurance protocols. They implement multi-tiered supplier verification processes, which can include audits, continuous performance monitoring, and partnerships with independent testing laboratories. Furthermore, many platforms offer guaranteed services, providing buyers with peace of mind that the parts they receive are authentic and traceable. This establishment of trust and quality control is the bedrock upon which these platforms build their credibility and value proposition.

-

Streamlined Logistics and Supply Chain Integration: A global transaction is only as good as its delivery. These platforms simplify the complex logistics of international shipping, customs clearance, and last-mile delivery. They often feature integrated logistics partners, allowing buyers to get instant shipping quotes and track shipments from the warehouse to their production line seamlessly. This end-to-end management streamlines the entire procurement lifecycle, reducing administrative overhead and ensuring that critical components arrive where and when they are needed.

Strategic Advantages for Modern Businesses

Adopting a Global Chip Spot Platform is not merely a tactical move for emergency sourcing; it is a strategic decision that confers several long-term competitive advantages. Companies that integrate these platforms into their overall supply chain strategy build a more resilient and responsive operation.

-

Enhanced Supply Chain Resilience and Risk Mitigation: Relying solely on a single source or a handful of Franchised Distributors (FDs) creates a single point of failure. The chip shortage demonstrated how a disruption at one factory or in one region could ripple across the entire industry. By incorporating a Global Chip Spot Platform into their strategy, companies create a diversified sourcing portfolio. When their primary supplier cannot deliver, they have an immediate, global alternative to tap into. This diversification is a critical form of supply chain risk mitigation, ensuring business continuity even in volatile market conditions.

-

Acceleration of Innovation and Time-to-Market: In competitive sectors like consumer electronics, automotive technology, and IoT, speed is everything. A delay of just a few weeks in sourcing a critical component can mean missing a crucial market window. The agility offered by a spot platform allows R&D teams and product managers to source obsolete, end-of-life (EOL), or simply hard-to-find components quickly. This capability is vital for maintaining legacy systems, supporting product repairs, and accelerating the prototyping phase for new products, thereby significantly reducing time-to-market.

-

Significant Cost Optimization and Spend Management: While spot prices can sometimes be higher than long-term contract prices during shortages, they offer significant cost-saving opportunities during market stabilization or oversupply periods. Procurement teams can use the platform’s data to identify fair market prices and avoid overpaying. Furthermore, the ability to quickly find alternative components or substitute parts can prevent costly production line stoppages. The overall effect is a more dynamic and intelligent approach to procurement cost optimization.

Navigating the Future with Global Chip Spot Platforms

The evolution of these platforms is far from over. The future will see them becoming even more integrated and intelligent, leveraging emerging technologies to provide deeper value.

-

The Role of AI and Machine Learning: The next generation of platforms will be powered by advanced AI algorithms that do more than just display data—they will predict it. Predictive analytics will forecast price movements and inventory shortages weeks or months in advance, allowing companies to proactively adjust their sourcing strategies. Machine learning will also personalize the user experience, recommending suppliers and components based on a company’s unique purchasing history and preferences.

-

Integration with Enterprise Systems: For maximum efficiency, data from spot platforms must flow seamlessly into a company’s internal systems. Future developments will focus on deeper API integrations with Enterprise Resource Planning (ERP), Material Requirements Planning (MRP), and Supply Chain Management (SCM) software. This creates a unified digital thread, where sourcing data automatically updates inventory levels, financial records, and production schedules.

-

Building a Collaborative Ecosystem: The ultimate value of a Global Chip Spot Platform lies in its network effect. As more reputable buyers and sellers join, the liquidity and reliability of the marketplace increase for everyone. Forward-thinking platforms are expanding their services to include financing options, demand forecasting for suppliers, and community-driven insights, fostering a collaborative ecosystem rather than just a transactional marketplace.

Conclusion

The emergence and rapid adoption of the Global Chip Spot Platform signify a fundamental shift in electronics supply chain management. It is a direct response to the growing complexity and volatility of the global market. These platforms are no longer a niche tool for desperate buyers but a core component of a modern, agile, and resilient procurement strategy. They provide the transparency, speed, and security needed to navigate challenges ranging from global shortages to rapid innovation cycles. By harnessing the power of real-time data, rigorous quality controls, and a global network of suppliers, businesses can not only survive disruptions but thrive in spite of them. In this new era, success will belong to those who can adapt fastest, and mastering the use of dynamic sourcing tools like those aggregated and analyzed through services such as ICGOODFIND is no longer optional—it is essential for sustainable growth and competitive advantage.