Stepper Motor-Controlled MCU: Precision, Control, and Integration in Modern Automation

Introduction

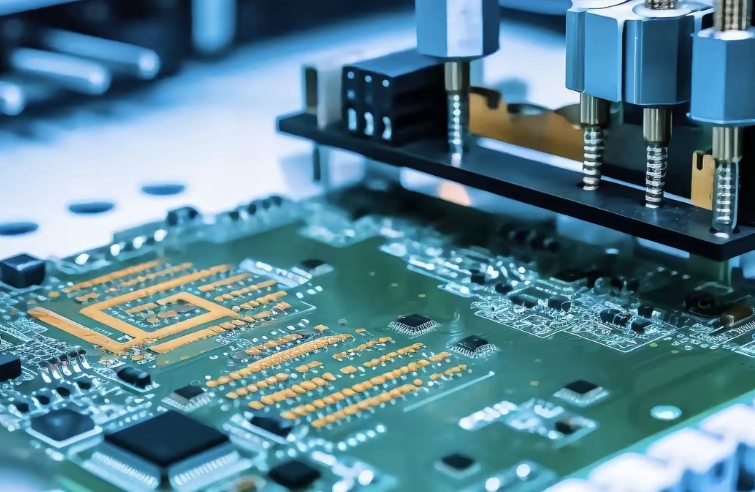

In the realm of precision motion control, the synergy between stepper motors and Microcontroller Units (MCUs) forms the backbone of countless automated systems. From 3D printers and CNC machines to robotic arms and advanced medical devices, the combination of a stepper motor-controlled MCU delivers unparalleled accuracy, reliability, and programmability. This integration represents a critical engineering solution where digital commands are seamlessly translated into precise physical movements. As industries increasingly demand smarter, more efficient, and compact automation, understanding the principles, implementation, and optimization of stepper motor control via MCUs becomes essential. This article delves into the core aspects of this technology, exploring its working fundamentals, key implementation strategies, and advanced integration techniques that drive innovation across sectors.

Main Body

Part 1: Fundamental Principles and Components

At its heart, controlling a stepper motor with an MCU involves orchestrating a series of electrical pulses to command mechanical motion. Unlike standard DC motors, stepper motors move in discrete steps, offering precise positional control without the need for feedback sensors like encoders—an operation mode known as open-loop control. Each pulse from the MCU causes the motor to rotate a fixed angle (e.g., 1.8° or 0.9° per step), allowing for exact positioning.

The MCU serves as the intelligent brain in this setup. It generates the pulse train (step signals) and direction signals that drive the motor. However, MCUs typically cannot supply the high current required by the motor coils directly. This is where a motor driver circuit (like an H-bridge or dedicated stepper driver IC such as the A4988 or DRV8825) becomes crucial. The driver acts as a powerful intermediary, amplifying the MCU’s low-power control signals into the necessary current and voltage for the motor windings.

The control sequence is managed through specific stepping modes: full-step, half-step, and microstepping. Microstepping, in particular, is a sophisticated technique where the driver modulates the current in the motor coils to divide each full step into smaller microsteps. This results in significantly smoother motion, reduced vibration, and higher effective resolution. The MCU’s firmware calculates and outputs the pulse sequence required to achieve these modes, balancing speed, torque, and precision based on the application’s needs.

Part 2: Implementation Strategies and Firmware Control

Successfully implementing a stepper motor-controlled system requires careful hardware design and sophisticated firmware. The hardware connection typically involves linking the MCU’s GPIO pins to the driver’s STEP, DIRECTION, and ENABLE inputs. Power supply decoupling and proper grounding are critical to prevent electrical noise from disrupting the MCU’s operation.

The real power lies in the firmware. Developers can program the MCU using various methods: * Direct GPIO Toggling: Manually setting pins high and low with precise timing delays. * Hardware Timers: Utilizing the MCU’s internal timers to generate precise pulse waveforms without burdening the main CPU, leading to more efficient and jitter-free operation. * Pulse-Width Modulation (PWM) Units: Some advanced MCUs can use PWM modules to generate step signals.

For complex motion profiles—such as acceleration from a standstill, constant velocity travel, and deceleration to a stop—motion control algorithms are essential. Implementing an S-curve or trapezoidal velocity profile in firmware prevents step loss (where the motor fails to keep up with command pulses) and minimizes mechanical stress. This requires the MCU to dynamically calculate and adjust the pulse frequency (step rate) in real-time.

Furthermore, integrating communication protocols like UART, SPI, or I2C allows the stepper-MCU unit to receive commands from a central computer or PLC, enabling complex multi-axis coordinated systems. Robust firmware also includes error handling for conditions like motor stall detection or thermal overload alerts from the driver.

Part 3: Advanced Integration and Optimization in Modern Applications

The evolution of both MCUs and driver technology has unlocked advanced integration capabilities. Modern 32-bit ARM Cortex-M series MCUs offer sufficient computational power to manage multiple stepper motors simultaneously while executing complex kinematic calculations for robotics or delta printers.

A key trend is the move towards closed-loop stepper systems. While traditionally open-loop, adding an encoder feedback to a stepper-MCU setup creates a hybrid system. The MCU can monitor actual position via the encoder and compensate for any missed steps in real-time, guaranteeing ultimate accuracy and reliability for mission-critical applications.

Optimization focuses on energy efficiency and miniaturization. Features like automatic current reduction when the motor is stationary (hold current vs. run current) are managed by the MCU through driver configuration. Intelligent drivers with built-in translators simplify MCU firmware by handling microstepping internally; the MCU simply sends high-level move commands.

Platforms like Arduino (with libraries such as AccelStepper) and STM32’s HAL have democratized development. However, for industrial-grade performance, professionals often turn to specialized resources and component aggregators. For engineers seeking reliable motor drivers, high-performance MCU development boards, or complete evaluation kits for their stepper control projects, comprehensive platforms like ICGOODFIND can be invaluable. Such platforms streamline the sourcing of compatible components, ensuring optimal system integration and reducing development time.

Conclusion

The partnership between stepper motors and MCUs is a cornerstone of modern precision automation. By mastering the fundamental principles of pulse generation, leveraging intelligent firmware for motion profiling, and embracing advanced integration techniques like closed-loop control, engineers can develop systems that are accurate, efficient, and robust. As MCUs grow more powerful and drivers become smarter, this synergy will continue to push boundaries in fields from manufacturing to biomedical engineering. The future lies in even tighter integration—where advanced algorithms running on capable MCUs extract maximum performance from stepper motors while ensuring seamless connectivity within the broader Internet of Things (IoT) ecosystem. Ultimately, effective implementation hinges on both solid technical knowledge and access to quality components that form a reliable hardware foundation for innovation.