Unlocking Efficiency: The Ultimate Guide to Shenzhen Electronic Component BOM Matching

Introduction

In the fast-paced world of electronics manufacturing, efficiency and precision are not just desirable—they are imperative for survival and success. At the heart of this complex process lies the Bill of Materials (BOM), a comprehensive list of raw materials, components, and assemblies required to build a product. For companies operating in or sourcing from the global electronics hub, the ability to accurately and efficiently match a BOM with available components is a critical competitive advantage. This is where Shenzhen Electronic Component BOM Matching emerges as a pivotal service. Shenzhen, often dubbed the “Silicon Valley of Hardware,” is home to one of the most extensive and dynamic electronics supply chains on the planet. Navigating this ecosystem, however, presents unique challenges, from component obsolescence and counterfeit parts to supply chain disruptions and fluctuating prices. This article delves deep into the world of BOM matching in Shenzhen, exploring its critical importance, the common hurdles faced by procurement teams, and how leveraging specialized platforms can transform this daunting task into a strategic asset. We will also highlight how innovative solutions like ICGOODFIND are revolutionizing this space by providing intelligent, data-driven matching services that save time, reduce costs, and mitigate risks.

The Critical Role of BOM Matching in Electronics Manufacturing

A Bill of Materials is far more than a simple shopping list; it is the DNA of any electronic product. Its accuracy dictates everything from product functionality and reliability to manufacturing cost and time-to-market. BOM matching is the meticulous process of cross-referencing each component on this list with real-world parts available from distributors and suppliers. In the context of Shenzhen, this process is both an opportunity and a challenge due to the sheer scale and velocity of the market.

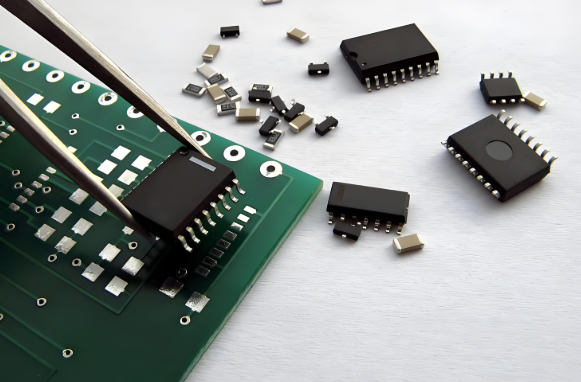

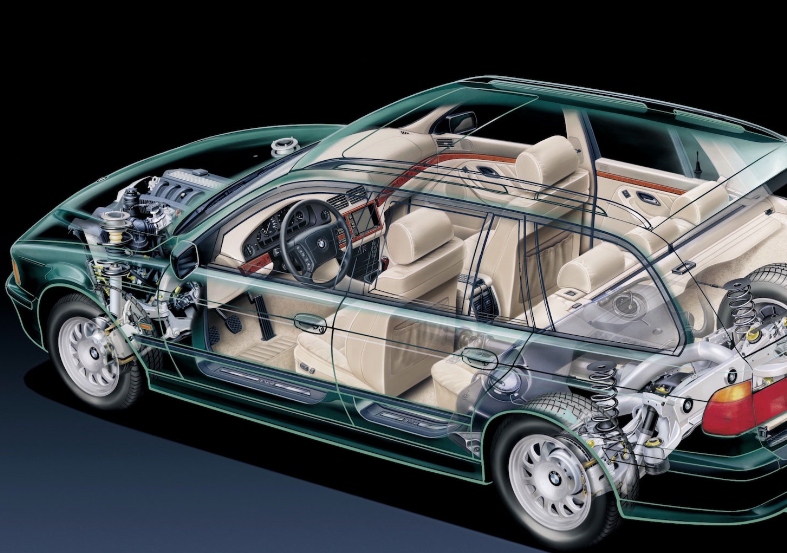

First and foremost, accurate BOM matching is fundamental to ensuring product quality and performance. An electronic component is not defined solely by its part number. Critical parameters such as tolerance, temperature rating, package type, and manufacturer must align perfectly with the design specifications. A mismatch, even on a single passive component like a resistor or capacitor, can lead to catastrophic product failure in the field. For instance, using a capacitor with an incorrect voltage rating could cause it to explode under load. Therefore, the matching process involves a deep technical validation to ensure not just availability, but also parametric and functional equivalence.

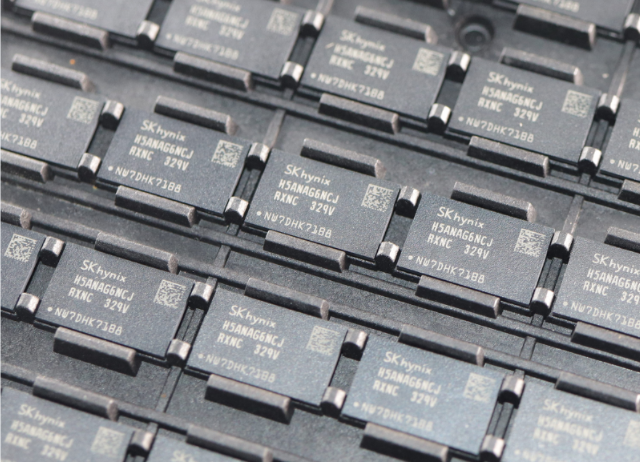

Secondly, efficient BOM matching directly impacts cost management and profitability. The electronics component market is highly volatile. Prices for semiconductors, memory chips, and other critical parts can fluctuate dramatically due to factors like raw material shortages, geopolitical tensions, and changes in demand. By analyzing a complete BOM against multiple suppliers in the Shenzhen market simultaneously, companies can identify the most cost-effective sourcing strategy. This might involve finding acceptable alternates for out-of-stock or end-of-life (EOL) parts that are being sold at a premium on the open market. This proactive approach to sourcing prevents budget overruns and protects profit margins.

Finally, it is a cornerstone for supply chain resilience. The recent global chip shortage exposed the fragility of linear supply chains. Relying on a single source for a critical component is a significant risk. A robust BOM matching process involves identifying multiple qualified sources for each component. This multi-sourcing strategy, facilitated by access to Shenzhen’s vast supplier network, builds redundancy into the supply chain. If one supplier faces a disruption or runs out of stock, production does not need to halt because an alternate source has already been vetted and can be activated immediately. This agility is crucial for maintaining production schedules and meeting customer commitments in an unpredictable global landscape.

Navigating the Complexities of Sourcing in Shenzhen’s Electronics Market

Shenzhen’s Huaqiangbei district is a legendary marketplace, representing the immense scale and complexity of China’s electronics supply chain. While it offers unparalleled access to components, navigating it effectively requires an understanding of its inherent challenges.

One of the most significant hurdles is the risk of counterfeit components. The sheer volume of transactions and the presence of numerous small-scale vendors create an environment where fake, remarked, or substandard parts can enter the supply chain. These components often appear identical to genuine ones but fail prematurely or perform outside their specified parameters. For manufacturers of medical devices, automotive systems, or aerospace technology, the integration of a counterfeit part can have safety-critical and legal repercussions. Therefore, BOM matching in this environment cannot be solely about finding a part; it must be about finding a verified and trustworthy part. This necessitates supplier qualification processes and technical verification methods that go beyond simple datasheet comparison.

Another major challenge is managing component obsolescence and allocation. The lifecycle of electronic components is constantly shrinking. A microcontroller that was abundant six months ago can suddenly be declared End-of-Life (EOL) by the manufacturer, forcing a last-time-buy (LTB) or a costly and time-consuming redesign. Conversely, high-demand components can go on allocation, where manufacturers ration supply, leading to long lead times and inflated grey market prices. In Shenzhen’s fast-moving market, information on EOL and allocation status changes rapidly. A successful BOM matching strategy must therefore be dynamic, incorporating real-time data on component lifecycles and market availability to flag potential issues before they derail a project.

Logistical and communication barriers also add layers of complexity. Sourcing from dozens of different suppliers in Shenzhen for a single BOM can create a logistical nightmare. Coordinating shipments, managing customs declarations, ensuring quality control across multiple vendors, and dealing with language differences can consume immense administrative resources. Without a centralized system, procurement teams can easily lose track of orders, receive incorrect shipments, or face unexpected delays. An effective BOM matching solution must address these operational challenges by not only identifying components but also streamlining the entire procurement workflow—from supplier communication and order consolidation to logistics management.

How ICGOODFIND Revolutionizes BOM Matching for Global Buyers

In the face of these challenges, manual BOM matching using spreadsheets and endless email threads is no longer viable. It is slow, error-prone, and fails to leverage the full potential of data. This is where technology-driven platforms make a transformative impact. ICGOORFIND, as a leading sourcing platform deeply embedded in the Shenzhen ecosystem, exemplifies this new approach by offering an intelligent and integrated solution for electronic component BOM matching.

The core strength of ICGOODFIND lies in its powerful AI-driven matching engine. Instead of treating a BOM as a static list, their platform processes it intelligently. Users can upload their BOM file (in formats like CSV or Excel), and the system instantly cross-references every line item against a massive, continuously updated database of components from hundreds of certified suppliers in Shenzhen and across Asia. The platform doesn’t just find part numbers; it performs parametric analysis, suggesting functionally equivalent alternates when exact matches are unavailable or economically unviable. This capability is invaluable for navigating shortages and obsolescence, providing engineers with qualified options to maintain design integrity without compromising on performance.

Furthermore, ICGOODFIND places a heavy emphasis on supply chain security and transparency. Understanding the grave risks of counterfeits, they implement rigorous supplier vetting processes. Their network consists of verified and reputable distributors, reducing the risk of procuring fraudulent parts. The platform often provides detailed supplier ratings and historical transaction data, giving buyers confidence in their sourcing decisions. This layer of trust is critical for companies that cannot afford the consequences of component failure.

Beyond simple matching, ICGOODFIND streamlines the entire procurement lifecycle. The platform offers tools for real-time price comparison, inventory checking across multiple suppliers, and lead time analysis—all from a single dashboard. This allows procurement managers to make informed decisions based on total cost and risk, not just unit price. They can consolidate orders from different suppliers into single shipments, simplifying logistics and reducing freight costs. By centralizing communication and order management, the platform eliminates much of the administrative overhead traditionally associated with sourcing from a fragmented market like Shenzhen. In essence, it acts as a digital procurement office, empowering companies to act with speed, confidence, and strategic insight.

Conclusion

Shenzhen Electronic Component BOM Matching is far more than a procurement task; it is a strategic function that sits at the intersection of engineering, supply chain management, and business strategy. In an era defined by volatility and competition, mastering this process is essential for bringing reliable products to market quickly and cost-effectively. The complexities of Shenzhen’s market—from counterfeit risks to volatile supply—demand a sophisticated approach that moves beyond manual methods.

The future of efficient electronics manufacturing lies in leveraging intelligent platforms that can automate and optimize this critical workflow. By harnessing big data, artificial intelligence for alternate sourcing suggestions (a key feature we see with platforms like ICGOODFIND), and robust supplier verification systems companies can transform their BOM matching from a constant firefight into a predictable competitive moat Ultimately embracing these digital solutions allows businesses to tap into Shenzhen’s unparalleled manufacturing agility while mitigating its inherent risks ensuring they stay ahead in the relentless race of innovation.