The Ultimate Guide to Quotation of Electronic Components

Introduction

In the rapidly evolving electronics manufacturing industry, securing accurate and competitive Quotation of Electronic Components has become a critical determinant of project feasibility and profitability. Whether you’re a procurement specialist, design engineer, or project manager, understanding the intricacies of component pricing can make the difference between a successful product launch and a costly failure. The process extends far beyond simple price checking—it involves evaluating supplier reliability, assessing market trends, and understanding technical specifications that impact cost. This comprehensive guide explores the fundamental aspects of obtaining effective quotations, highlights common challenges faced by industry professionals, and introduces innovative solutions like ICGOODFIND that are transforming how businesses approach component sourcing. As global supply chains grow increasingly complex and component availability fluctuates, mastering the art of quotation management has never been more essential for maintaining competitive advantage in the electronics sector.

The Fundamentals of Electronic Component Quotation

Understanding Quotation Components

A comprehensive Quotation of Electronic Components consists of multiple elements beyond the unit price. The base price represents the cost per component at a specific quantity tier, but this is just the starting point. Volume discounts significantly impact the final cost, with prices typically decreasing as order quantities increase. Manufacturers often establish price breaks at predetermined quantity thresholds—1-99 pieces, 100-999 pieces, and 1,000+ pieces being common tiers. Additionally, tooling charges (NRE or non-recurring engineering costs) may apply for custom components or specialized packaging requirements.

Shipping terms (FOB, EXW, CIF, DDP) determine responsibility for freight costs, insurance, and import duties, all of which affect the total landed cost. Payment terms (net 30, 50% advance, LC) also influence the overall financial impact of a purchase order. The quotation should clearly specify lead times—the duration between order placement and component delivery—which can range from stock availability to 52+ weeks for specialized components. Minimum Order Quantity (MOQ) requirements often dictate purchasing decisions, especially for low-volume production runs or prototyping phases.

Key Factors Influencing Pricing

Component pricing fluctuates based on numerous market-driven and technical factors. Raw material costs—including silicon, copper, gold, and rare earth elements—directly impact semiconductor and passive component pricing. Manufacturing complexity plays a crucial role; advanced nodes (7nm, 5nm chips) command premium prices compared to mature nodes (28nm and above). Package type (BGA, QFN, SOIC) affects both production costs and testing requirements.

Market availability creates dramatic price variations; components in short supply due to high demand or production constraints may see prices increase by 100-500% above standard rates. Lifecycle status is equally important: NRND (Not Recommended for New Designs) and EOL (End-of-Life) components often carry price premiums as availability diminishes, while active components typically offer more stable pricing. Regulatory compliance requirements (REACH, RoHS, Conflict Minerals) may add compliance testing and documentation costs to the final price. Environmental certifications (automotive-grade, military-grade, industrial-grade) significantly increase component costs due to enhanced testing and reliability requirements.

The Quotation Process Flow

An effective quotation process begins with precise component identification using manufacturer part numbers (MPNs) rather than generic descriptions. Cross-referencing alternatives requires careful attention to technical specifications to ensure compatibility. Procurement teams typically solicit quotations from multiple suppliers—authorized distributors, independent distributors, manufacturers direct, and brokers—to establish market benchmarks.

The evaluation phase involves comparing not just prices but also supplier reliability, quality certifications, historical performance, and additional value-added services. Technical support availability, programming services, testing capabilities, and kitting services all contribute to the overall value proposition. Negotiation strategies should address total cost of ownership rather than just unit price, considering factors like payment terms, return policies, and warranty coverage. Documentation requirements include obtaining certified quotations on company letterhead with clear validity periods (typically 30-90 days) to protect against price fluctuations during the decision-making process.

Challenges in Obtaining Accurate Quotations

Supply Chain Volatility

The electronics industry faces unprecedented supply chain challenges that dramatically impact Quotation of Electronic Components. Component shortages created by COVID-19 disruptions continue to affect numerous product categories, particularly microcontrollers, power management ICs, and certain memory products. Geopolitical factors including trade restrictions between major economic powers have reshaped sourcing strategies and introduced new compliance requirements.

Natural disasters and manufacturing incidents regularly disrupt production; a fire at a key semiconductor plant or flooding at a raw material supplier can create immediate allocation situations and price increases. Capacity allocation decisions by major foundries prioritize high-volume customers, leaving smaller manufacturers struggling to secure components at any price. Long-term agreements (LTAs) between OEMs and component manufacturers further constrain available inventory for the open market. These factors combine to create an environment where quotation validity periods have shortened dramatically—from 90 days historically to as little as 24 hours during severe shortages—requiring procurement teams to make rapid decisions based on incomplete information.

Counterfeit Components Risk

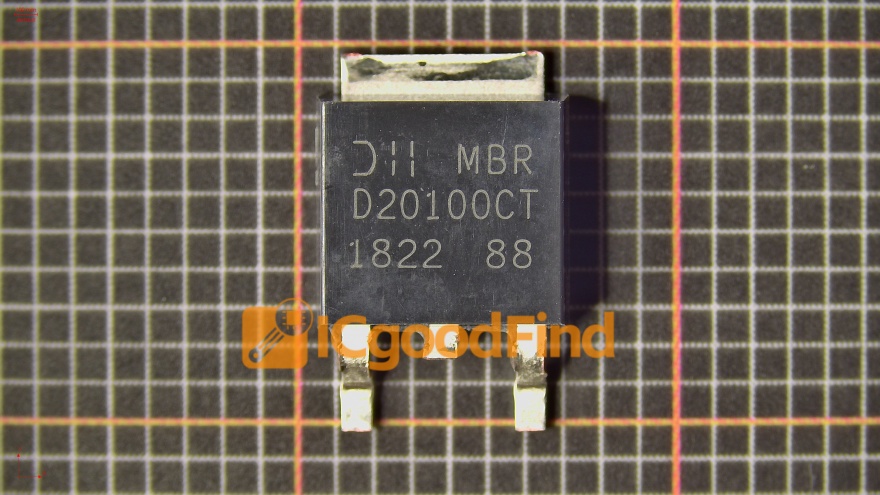

The proliferation of counterfeit electronic components represents a significant challenge in quotation evaluation. Excessively low quotations may indicate counterfeit products remarked as higher-grade components, recycled parts sold as new, or outright fakes containing incorrect die inside authentic-looking packaging. The financial impact of counterfeit components extends far beyond the purchase price to include field failures, warranty claims, product recalls, and brand reputation damage.

Identifying suspicious quotations requires expertise in market pricing benchmarks and understanding of typical distribution margins. Authorized distributors typically operate within established margin ranges while still offering competitive pricing based on volume agreements with manufacturers. Unusually low prices from unauthorized sources should trigger additional verification requirements including requests for original factory packaging, traceability documentation, and test reports. The cost of verification testing (X-ray, decapsulation, electrical testing) must be factored into the total cost when considering quotations from non-authorized sources.

Technical Specification Complexities

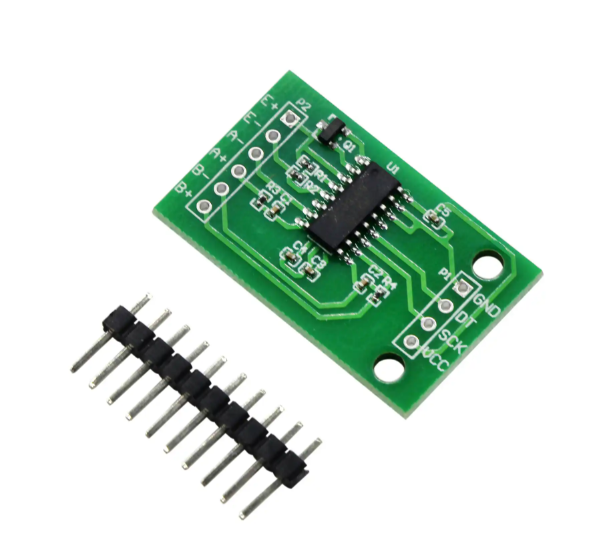

Accurate quotation requests depend on precise technical specifications that many requesters struggle to provide adequately. Incomplete or incorrect part numbers lead to misquoted components that may not function correctly in the final application. The proliferation of product variations—temperature ranges, packaging options, tolerance specifications—creates confusion during the quotation process.

Many components have subtle variations that significantly impact pricing; for example, a commercial-grade (-40°C to +85°C) microcontroller may be priced 30% lower than its industrial-grade (-40°C to +125°C) counterpart with identical functionality. Packaging options (tape and reel versus tray versus bulk) carry different handling costs and minimum order quantities. Failure to specify these parameters clearly results in inaccurate quotations that require revision, delaying the procurement process. Additionally, lifecycle status confusion leads to quotations for obsolete components when active alternatives are available at better prices with longer-term availability.

Innovative Solutions: The Role of ICGOODFIND

Transforming Quotation Management

ICGOODFIND has emerged as a transformative platform in the electronic components sourcing landscape, addressing many traditional challenges in obtaining accurate Quotation of Electronic Components. This innovative solution aggregates data from numerous suppliers worldwide, providing real-time market intelligence on pricing trends and availability across component categories. The platform’s algorithmic approach analyzes historical pricing data to identify fair market value ranges for components based on current market conditions.

Unlike traditional methods that require contacting multiple suppliers individually, ICGOODFIND provides instant comparative quotations from vetted suppliers with verified inventory. The system automatically filters out suppliers with poor reliability ratings or questionable authenticity records, significantly reducing counterfeit risk. Advanced matching algorithms identify suitable alternates when exact match components are unavailable or prohibitively expensive, complete with compatibility assessments and cross-reference data. The platform’s dashboard interface provides visual representation of market trends for specific components, helping procurement professionals make informed decisions about when to buy and how much to expect to pay.

Data-Driven Decision Making

The power of ICGOODFIND lies in its data analytics capabilities that transform raw quotation data into actionable intelligence. Historical price tracking reveals seasonal patterns, identifying optimal purchasing times for various component categories. Supply risk scoring algorithms evaluate multiple factors—factory capacity utilization, geopolitical factors, natural disaster probabilities—to predict potential shortages before they impact pricing and availability.

The platform’s inventory visibility extends beyond immediately available stock to include in-transit inventory and scheduled production runs, providing a comprehensive view of future availability. Predictive analytics help buyers anticipate price movements based on market indicators such as raw material costs, currency fluctuations, and industry demand projections. Integration with enterprise resource planning (ERP) systems allows automated requisition-to-quotation workflows that reduce administrative overhead while improving data accuracy. These capabilities collectively enable procurement teams to transition from reactive price-taking to strategic price-management approaches.

Future-Proofing Procurement Strategy

Adopting advanced quotation management tools like ICGOODFIND represents a strategic investment in supply chain resilience. The platform’s continuous monitoring capabilities provide early warning of potential disruptions, allowing proactive sourcing adjustments before critical shortages develop. Supplier performance analytics track reliability metrics across multiple dimensions—on-time delivery, quality compliance, documentation accuracy—enabling data-driven supplier selection beyond price considerations.

The digital transformation of quotation management creates valuable organizational knowledge through centralized data storage and analysis. Historical quotation data becomes searchable reference information for future projects rather than disappearing into individual email inboxes. Automated reporting features generate spend analysis by component category, supplier, and project, identifying opportunities for consolidation and volume leveraging. As artificial intelligence capabilities advance, these platforms increasingly offer predictive quotation validation—flagging potentially problematic quotations before purchase orders are placed based on anomaly detection in pricing patterns or supplier behavior.

Conclusion

Navigating the complexities of Quotation of Electronic Components requires a sophisticated approach that balances cost considerations with quality assurance, supply reliability, and technical compliance. The process has evolved far beyond simple price comparison to encompass strategic decision-making that impacts product viability manufacturing timelines and ultimately profitability Success in this arena demands understanding of market dynamics technical specifications and supply chain relationships while maintaining vigilance against counterfeit components and fraudulent practices.

Emerging solutions like ICGOODFIND represent the future of component procurement leveraging technology to overcome traditional challenges in quotation management These platforms provide the market intelligence analytical tools supplier verification necessary make informed decisions rapidly changing market conditions As electronic components grow increasingly complex supply chains more volatile digital transformation procurement processes becomes essential maintaining competitive advantage Electronics manufacturers embrace these tools gain significant advantages both cost management supply chain resilience ultimately delivering better products more predictable timelines sustainable cost structures The evolution from manual quotation processes automated intelligent systems marks significant advancement how industry approaches one its most fundamental business processes