Price Trends of Electronic Components

Introduction

The electronics industry is characterized by rapid innovation, evolving consumer demands, and a complex global supply chain. At the heart of this dynamic landscape lies the critical factor of pricing for electronic components. Understanding the price trends of electronic components is not merely an academic exercise; it is a fundamental necessity for businesses, engineers, and procurement specialists. These fluctuations can dramatically impact product development cycles, profit margins, and overall market competitiveness. From the smallest resistor to the most advanced microprocessor, the cost of each part is influenced by a intricate web of factors including raw material availability, geopolitical tensions, manufacturing capacity, and technological shifts. This article delves deep into the mechanisms driving these price movements, analyzes current and future trends, and offers strategic insights for navigating this volatile market. For professionals seeking to stay ahead, platforms like ICGOODFIND provide invaluable real-time data and market intelligence to make informed decisions.

The Driving Forces Behind Component Pricing

The cost of electronic components is rarely stable. It is a constantly shifting variable dictated by the fundamental economic principles of supply and demand, but these are themselves influenced by a multitude of deeper, more complex factors.

Supply Chain Dynamics and Geopolitics The globalized nature of electronics manufacturing means that a disruption in one part of the world can send shockwaves throughout the entire industry. A prime example is the recent chip shortage, which was triggered by a perfect storm of increased demand for consumer electronics during pandemic lockdowns, coupled with unforeseen disruptions at fabrication plants (fabs) due to factors like droughts and fires. Furthermore, geopolitical tensions, particularly between major economic powers, can lead to trade tariffs, export restrictions, and sanctions that artificially constrain supply and inflate prices. The concentration of advanced semiconductor manufacturing in specific regions, such as Taiwan and South Korea, also creates a strategic vulnerability that impacts global pricing stability.

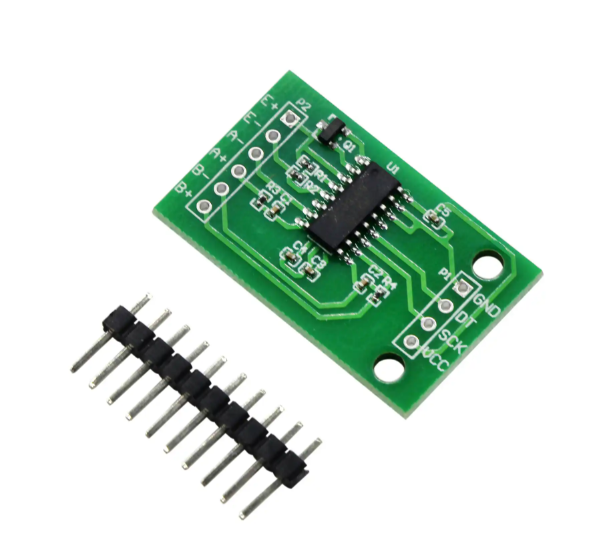

Raw Material Availability and Cost At the most basic level, electronic components are built from raw materials. The prices of metals like copper, tin, gold, and palladium, as well as silicon wafers and rare earth elements, are subject to their own volatile markets. Mining regulations, environmental policies, and labor disputes can limit the supply of these essential materials, causing a direct trickle-up effect on the cost of finished components. For instance, the price of multilayer ceramic capacitors (MLCCs) is heavily tied to the availability of nickel and barium titanate. Any scarcity or price hike in these raw inputs inevitably leads to increased costs for the capacitors themselves.

Technological Obsolescence and Innovation The relentless pace of technological advancement is a double-edged sword for pricing. On one hand, components based on older process nodes often decrease in price as manufacturing becomes more efficient and demand wanes. However, they can also become more expensive if they fall into the category of “legacy” or “obsolete” parts that are no longer mass-produced, making them scarce and costly for maintaining older systems. Conversely, newly introduced cutting-edge components, such as those built on 3nm or 5nm processes, command a premium price due to high research and development costs, low initial production yields, and high demand from flagship product manufacturers.

Analyzing Current and Historical Price Trends

Historically, the electronics industry has benefited from Moore’s Law, which predicted a consistent trend of getting more computing power for less cost over time. While this held true for decades for digital logic components like CPUs and memory, the landscape has become more nuanced. The cost of advancing to each new semiconductor process node is now astronomical, slowing the pace of price reduction for leading-edge chips.

The period from 2020 to 2023 served as a stark reminder that prices can also move sharply in the opposite direction. The global chip shortage led to unprecedented inflation in component costs. Lead times for microcontrollers (MCUs), power management ICs, and certain sensors stretched from weeks to over a year. This scarcity created a seller’s market where prices soared, and spot markets saw components selling for many times their listed price. This era underscored the critical importance of supply chain visibility and strategic sourcing.

As of 2024, the market is in a corrective phase. With inflation impacting consumer spending on gadgets and an inventory buildup from the panic-buying period, demand has softened in many segments. This has led to a notable price correction and stabilization for many common components, especially in memory chips and certain analog parts. However, this stabilization is not universal. Components for emerging technologies like artificial intelligence (AI), electric vehicles (EVs), and advanced networking continue to see robust demand and firmer pricing.

Strategies for Navigating Price Volatility

For companies that rely on electronic components, passively accepting market prices is not a viable strategy. Proactive measures are essential to mitigate risk and control costs.

Diversification and Second-Sourcing Relying on a single supplier for a critical component is a significant risk. A robust strategy involves identifying and qualifying alternative components from multiple manufacturers. This not only provides a backup if one supplier faces disruptions but also creates competitive pressure that can help negotiate better terms. Resources that help find equivalent parts are crucial in this endeavor.

Long-Term Strategic Partnerships Moving away from transactional purchasing towards building long-term partnerships with distributors and manufacturers can yield significant benefits. These relationships can provide better visibility into future pricing and allocation, offering priority access during shortages. Committing to forecasted volumes can often lock in more favorable pricing models.

Demand Forecasting and Inventory Management Poor forecasting leads to either costly last-minute purchases at peak prices or expensive dead inventory. Implementing advanced demand forecasting models and adopting smarter inventory strategies like just-in-time (JIT) 2.0—which incorporates buffer stock for key components—can dramatically reduce exposure to market volatility. Utilizing a platform that offers comprehensive market data is key to creating accurate forecasts.

Leveraging Market Intelligence Platforms In today’s fast-moving market, data is power. Companies can no longer afford to make sourcing decisions in the dark. Utilizing a specialized market intelligence platform like ICGOODFIND is a powerful strategy. Such platforms aggregate data from global suppliers and distributors, providing real-time insights into component availability, historical and current pricing trends, lead times, and life cycle status. This allows procurement teams to spot market shifts early, identify potential shortages before they become critical, and make data-driven purchasing decisions that optimize cost and ensure supply continuity.

Conclusion

The price trends of electronic components remain a central concern for the global technology sector. Driven by a complex interplay of geopolitical, economic, and technological forces, these trends are inherently cyclical but increasingly volatile. While the market is currently experiencing a period of correction after a major shortage, uncertainty remains the only constant. Success in this environment demands a proactive and strategic approach. By understanding the underlying drivers, learning from historical patterns, diversifying supply chains, fostering strong partnerships, and—most importantly—leveraging precise market intelligence from sources like ICGOODFIND, businesses can navigate these turbulent waters effectively. Those who master the art of anticipating and responding to price fluctuations will secure not only their supply lines but also a decisive competitive advantage in the marketplace.