Asia Electronic Component BOM Matching: Streamlining Supply Chain Efficiency

Introduction

In the fast-paced world of electronics manufacturing, Asia Electronic Component BOM Matching has emerged as a critical process that can make or break production timelines and product quality. The Bill of Materials (BOM) serves as the foundational blueprint for any electronic product, containing every component required for manufacturing. However, in today’s complex global supply chain, simply having a BOM isn’t enough - the ability to accurately match these components with reliable suppliers has become a strategic imperative. Asian markets, particularly China, Taiwan, South Korea, and Japan, dominate the global electronics component manufacturing landscape, making efficient BOM matching in this region crucial for electronics companies worldwide. The process involves not just finding components that meet technical specifications, but also ensuring availability, competitive pricing, and compliance with industry standards. As supply chain disruptions continue to challenge manufacturers, sophisticated BOM matching solutions have become essential tools for maintaining production continuity and competitive advantage. Companies like ICGOODFIND have recognized this growing need and developed specialized platforms that streamline the component sourcing process, helping manufacturers navigate the complexities of Asian electronic markets with greater efficiency and confidence.

The Critical Importance of BOM Matching in Asian Electronics Manufacturing

Understanding the Asian Electronics Component Ecosystem

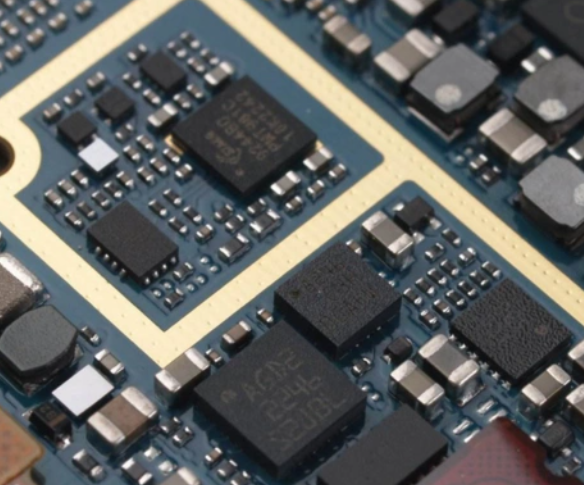

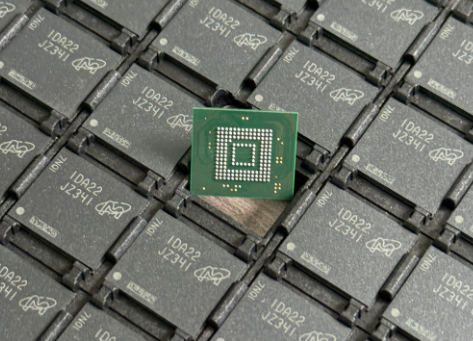

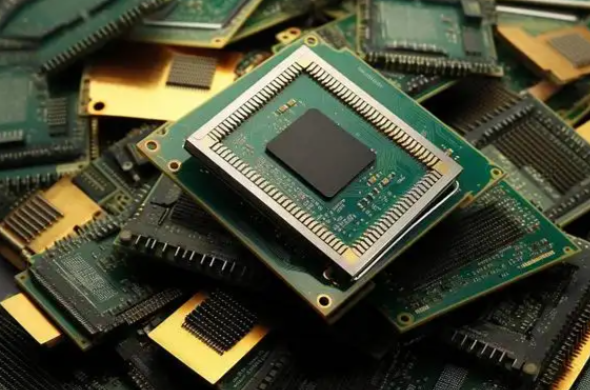

The Asian electronics component market represents a complex and dynamic ecosystem that requires specialized knowledge to navigate effectively. China has established itself as the world’s manufacturing hub, producing everything from basic passive components to advanced semiconductors. Meanwhile, Taiwan dominates the semiconductor foundry market, with TSMC leading global chip manufacturing. South Korea excels in memory chips and display technologies, while Japan maintains strength in high-quality passive components, sensors, and specialized materials. This geographic specialization means that a complete BOM often requires sourcing from multiple Asian countries, each with their own business practices, quality standards, and supply chain characteristics. The diversity of this landscape makes comprehensive BOM matching particularly challenging yet critically important. Manufacturers must account for regional variations in component quality, counterfeit risks, logistics considerations, and regulatory compliance - all while maintaining cost efficiency and production schedules.

The complexity of Asian electronic component sourcing is further compounded by frequent supply chain disruptions, geopolitical tensions, and rapidly changing market conditions. The COVID-19 pandemic exposed vulnerabilities in global electronics supply chains, with factory shutdowns and logistics bottlenecks causing widespread component shortages. More recently, trade tensions between the US and China have created additional complications for companies sourcing components from Asian markets. In this environment, effective BOM matching goes beyond simple part number matching - it requires deep market intelligence, alternative part identification capabilities, and risk assessment tools that can help manufacturers navigate uncertainty. Advanced BOM matching platforms incorporate real-time market data, supplier reliability metrics, and risk analytics to provide manufacturers with the insights needed to make informed sourcing decisions.

The Technical Challenges of Accurate BOM Matching

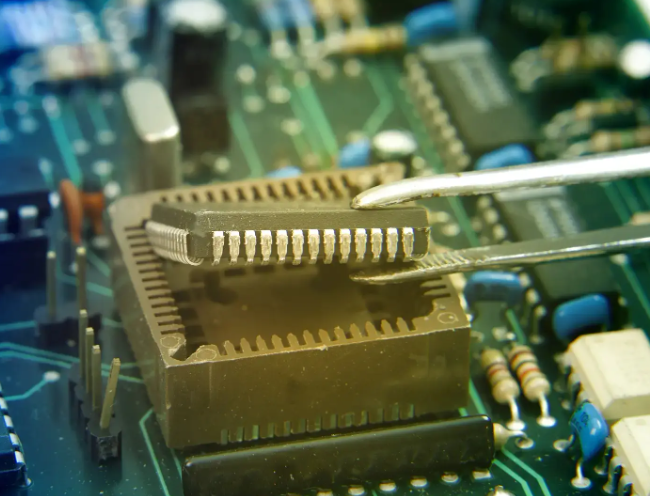

Accurate BOM matching in Asian markets presents significant technical challenges that require sophisticated solutions. One primary difficulty lies in component identification and cross-referencing. Different manufacturers may use varying part numbers for functionally similar components, while identical part numbers might indicate different components from various suppliers. This confusion is particularly prevalent in Asian markets where component documentation may be less standardized or available primarily in local languages. Additionally, the prevalence of counterfeit components in some Asian markets poses serious risks to product quality and reliability. Effective BOM matching must include verification processes that authenticate components and identify potential counterfeit risks before they enter the production line.

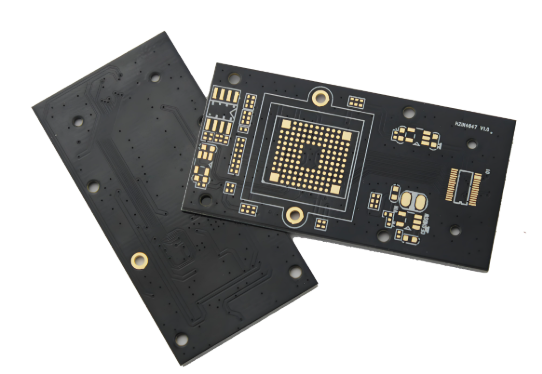

Another technical challenge involves specification matching and compliance verification. Electronic components must meet precise technical specifications to function correctly within a product design. However, subtle variations in performance characteristics between supposedly equivalent components from different manufacturers can lead to product failures or performance issues. Sophisticated BOM matching systems address this challenge by analyzing detailed technical parameters beyond basic part numbers, ensuring that alternative components meet all critical specifications. Furthermore, compliance with environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) adds another layer of complexity to component selection. With Asian manufacturers at various stages of compliance implementation, verification becomes an essential component of the matching process.

Advanced Strategies for Effective BOM Matching in Asia

Leveraging Technology for Efficient Component Sourcing

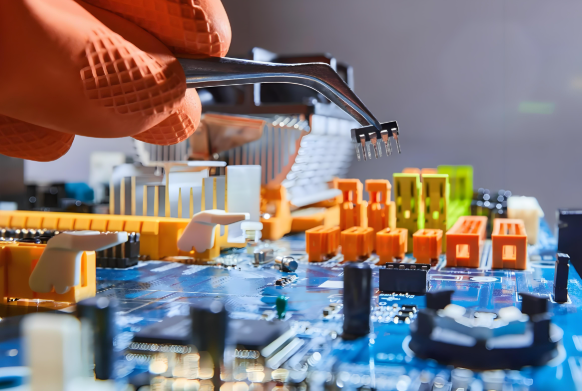

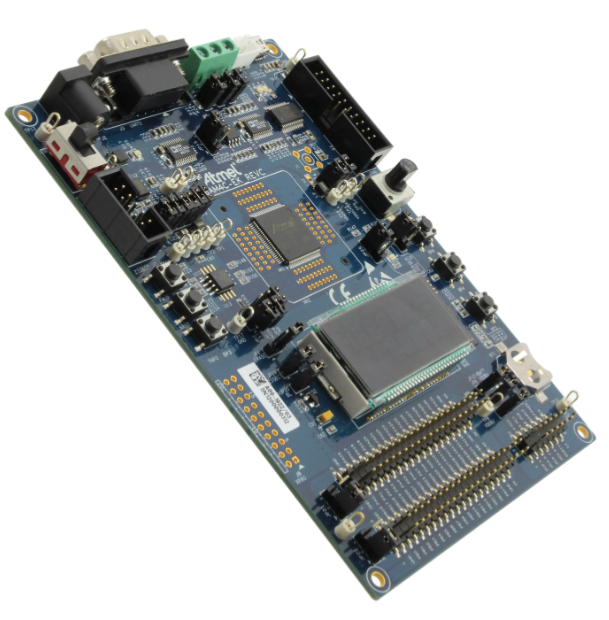

The digital transformation of electronics procurement has revolutionized BOM matching processes, with advanced technological solutions offering significant advantages over traditional methods. Artificial intelligence and machine learning algorithms now power sophisticated matching platforms that can analyze complete BOMs in seconds, identifying available components across global supplier networks while accounting for technical specifications, compliance requirements, and quality considerations. These systems continuously learn from sourcing outcomes, improving their recommendation accuracy over time. For companies operating in Asian markets, where information asymmetry has traditionally been a challenge, these AI-driven platforms provide unprecedented visibility into component availability, pricing trends, and supplier reliability.

Cloud-based BOM management platforms represent another technological advancement transforming component sourcing. These systems enable real-time collaboration between engineering, procurement, and manufacturing teams regardless of geographic location - a crucial capability when working across global organizations with design teams in one country and manufacturing operations in Asia. Modern platforms offer features such as automated alternate part identification, lifecycle status monitoring, price history tracking, and inventory management across multiple warehouses and suppliers. Some advanced systems even incorporate predictive analytics that forecast component shortages or price increases based on market intelligence, enabling proactive sourcing strategies. The integration of these technological capabilities creates a comprehensive ecosystem that supports informed decision-making throughout the component sourcing process.

Building Strategic Supplier Relationships

While technology plays an increasingly important role in BOM matching, the human element remains critical - particularly in Asian business contexts where personal relationships significantly influence commercial interactions. Developing strategic partnerships with reliable suppliers in key Asian electronics hubs provides manufacturers with advantages that technology alone cannot deliver. These relationships often yield benefits such as priority access to constrained components, advance notice of product changes or discontinuations, and more favorable pricing terms. In many Asian business cultures, trust built through long-term collaboration can be as important as contractual agreements in ensuring supply chain stability.

Effective supplier relationship management in Asian markets requires understanding regional business practices and communication styles. For example, suppliers in Japan typically emphasize quality and reliability above all else, while those in China may prioritize flexibility and responsiveness to changing requirements. Korean suppliers often excel in technological innovation but maintain rigid quality standards, while Taiwanese companies frequently offer a balance of technical capability and cost efficiency. Manufacturers who invest time in understanding these cultural nuances and building genuine partnerships typically achieve better outcomes in their BOM matching efforts than those who approach sourcing as purely transactional relationships. This strategic approach to supplier development complements technological solutions by creating a foundation of trust and mutual understanding that facilitates problem-solving when supply chain challenges inevitably arise.

The Future of Asia Electronic Component BOM Matching

Emerging Trends and Technologies

The field of Asia electronic component BOM matching is evolving rapidly, driven by technological innovation and changing market dynamics. Blockchain technology is emerging as a potential solution to counterfeit component risks by creating immutable records of component provenance and transaction history. Several pilot programs are underway in Asian electronics hubs exploring blockchain applications for component authentication and supply chain transparency. Similarly, Internet of Things (IoT) devices are being deployed throughout logistics networks to provide real-time tracking of component shipments from Asian factories to global manufacturing facilities. This enhanced visibility helps manufacturers better manage production schedules and inventory levels based on accurate delivery estimates.

Another significant trend is the growing integration of supply chain risk analytics into BOM matching platforms. These systems aggregate data from multiple sources - including geopolitical developments, weather patterns, financial indicators, and industry news - to identify potential disruptions before they impact component availability. For manufacturers dependent on Asian suppliers, these predictive capabilities are increasingly valuable in an era of heightened uncertainty. Additionally, advances in natural language processing are improving the ability of BOM matching systems to interpret technical documentation in various Asian languages, reducing barriers to comprehensive supplier evaluation. As these technologies mature, they will further automate and optimize the component sourcing process while enhancing risk management capabilities.

The Role of Specialized Platforms Like ICGOODFIND

Specialized BOM matching platforms have become essential tools for navigating the complexities of Asian electronic component sourcing. Companies like ICGOODFIND have developed sophisticated solutions specifically designed to address the unique challenges of this market. These platforms typically offer comprehensive databases of Asian component suppliers with detailed information about product offerings, quality certifications, production capabilities, and reliability metrics. By aggregating this information into user-friendly interfaces, they significantly reduce the time and effort required to identify suitable suppliers for specific component requirements.

The value proposition of specialized platforms extends beyond simple supplier identification. Advanced features such as real-time inventory checking across multiple distributors, price comparison tools, lifecycle status monitoring, and automated alternate part identification provide manufacturers with comprehensive support throughout the sourcing process. Some platforms even offer value-added services such as component testing/verification, quality assurance audits of suppliers, and logistics management support. For companies without extensive experience in Asian markets, these services can be invaluable in mitigating risks and ensuring successful outcomes. As supply chain complexity increases, the role of specialized platforms in facilitating efficient BOM matching will continue to grow, making them indispensable partners for electronics manufacturers worldwide.

Conclusion

Asia Electronic Component BOM Matching has evolved from a simple procurement activity to a strategic business process that directly impacts manufacturing efficiency, product quality, and competitive advantage. The complexity of Asian electronics markets demands sophisticated approaches that combine advanced technology with deep market knowledge and strategic relationship building. As supply chain disruptions continue to challenge manufacturers worldwide, the ability to efficiently match BOM requirements with reliable Asian suppliers has become more critical than ever. Technological solutions powered by AI, machine learning, and predictive analytics are transforming BOM matching processes, providing unprecedented visibility into component availability,pricing trends,and supplier reliability.Specialized platforms like ICGOODFIND play an increasingly important role in this ecosystem by aggregating market intelligence and streamlining supplier identification processes.

Looking ahead,the future of Asia electronic component BOM matching will be shaped by continued technological innovation,growing emphasis on supply chain resilience,and evolving geopolitical dynamics.Manufacturers who invest in developing robust BOM matching capabilities—whether through internal expertise or partnerships with specialized platform providers—will be better positioned to navigate uncertainty and maintain competitive advantage.Ultimately,in an industry where time-to-market and production continuity are paramount,efficient BOM matching represents not just an operational necessity but a strategic imperative for success in the global electronics marketplace.