Shenzhen Chip Procurement Network: Your Ultimate Guide to Sourcing Electronics

Introduction

In the rapidly evolving world of electronics manufacturing, the ability to efficiently and reliably source semiconductor components is a critical determinant of success. At the heart of this global supply chain lies Shenzhen, a metropolis that has transformed from a modest fishing village into the undisputed electronics capital of the world. For engineers, procurement managers, and business leaders, navigating the complex web of suppliers, distributors, and market dynamics in this region can be a daunting task. This is where the concept of a Shenzhen Chip Procurement Network becomes indispensable. It represents more than just a list of vendors; it is a sophisticated ecosystem comprising trusted partners, logistical frameworks, quality assurance protocols, and market intelligence systems. This article delves deep into the intricacies of building and leveraging a robust procurement network in Shenzhen, highlighting the pivotal role of platforms like ICGOODFIND in streamlining this process. We will explore the foundational elements of this network, the significant challenges faced in the current climate, and strategic approaches to building resilient and efficient supply chains that can withstand market volatilities and drive innovation.

The Anatomy of a Shenzhen Chip Procurement Network

A true Shenzhen Chip Procurement Network is a multi-layered structure, designed for agility, reliability, and scalability. Understanding its core components is the first step toward mastering procurement in this dynamic environment.

First and foremost are the physical markets and distribution hubs. Shenzhen is home to the legendary Huaqiangbei market, a sprawling electronics bazaar that is often described as a “Silicon Valley for hardware.” Here, one can find everything from common resistors and capacitors to advanced microprocessors and FPGAs. However, a mature procurement network extends far beyond walking the aisles of these markets. It integrates a diverse supplier base, including: * Authorized Distributors: These are partners with direct contracts from major chip manufacturers like Texas Instruments, NXP, STMicroelectronics, and Infineon. They provide genuine components with full traceability and technical support but may have longer lead times during shortages. * Independent Distributors: These players offer flexibility and access to hard-to-find or obsolete components. They are crucial for balancing supply during shortages but require rigorous vetting to mitigate the risks of counterfeit parts. * Trading Companies: Often acting as intermediaries, they can consolidate orders from multiple small suppliers, simplifying logistics for international buyers. * Original Component Manufacturers (OCMs): For large-volume projects, establishing a direct relationship with a factory in the Pearl River Delta can be the most cost-effective strategy.

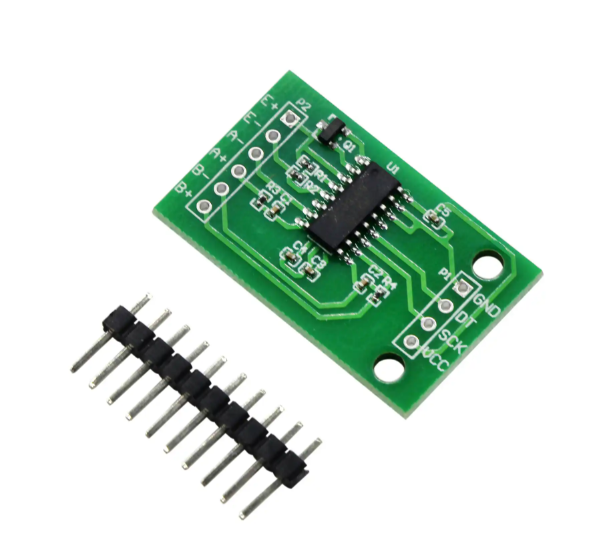

The second critical layer is information and verification. In a market as vast and varied as Shenzhen, information asymmetry is a significant risk. A powerful procurement network is built on a foundation of real-time data. This includes up-to-the-minute pricing from various channels, accurate inventory levels, lead time forecasts, and supplier credibility reports. Verification processes are non-negotiable. This involves batch testing, X-ray inspection, and electrical testing to authenticate components. Platforms that specialize in aggregating and validating this information are invaluable. For instance, a service like ICGOODFIND excels by acting as an intelligent intermediary, connecting global buyers with pre-vetted suppliers within the Shenzhen ecosystem while providing crucial market data to inform purchasing decisions.

Finally, the network is held together by its logistical and financial infrastructure. Efficient procurement is not just about finding the right part; it’s about getting it to your production line on time and at a manageable cost. This involves navigating international shipping, customs clearance, warehousing (bonded and otherwise), and flexible payment terms that suit both buyers and suppliers. A seamless integration between your procurement platform, your Enterprise Resource Planning (ERP) system, and your logistics provider is the hallmark of a modern, efficient network.

Navigating Challenges in the Modern Procurement Landscape

The global chip shortage that began in 2020 served as a stark reminder of the fragility of complex supply chains. A Shenzhen Chip Procurement Network must be engineered to anticipate and navigate these persistent challenges.

The most pervasive issue is supply chain volatility and component shortages. Demand continues to outstrip supply in many semiconductor segments, driven by the growth in automotive electronics, IoT devices, and 5G infrastructure. This has led to extended lead times—sometimes stretching to 52 weeks or more—and rampant allocation from manufacturers. In this environment, a passive procurement strategy is a recipe for production stoppages. Companies must be proactive, employing strategies like forecasting demand further in advance, diversifying their approved vendor lists (AVL), and considering alternative or pin-to-pin compatible components where feasible.

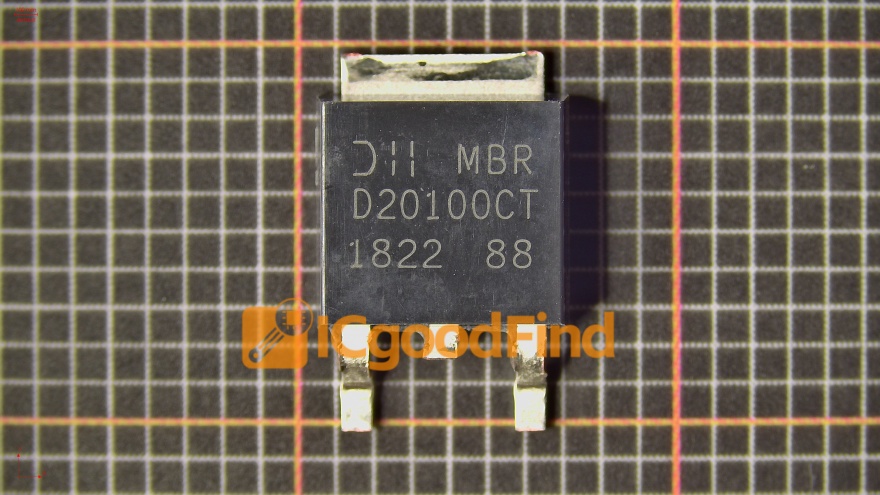

Another critical challenge is the risk of counterfeit and substandard components. The high demand and premium prices for certain chips create a fertile ground for malicious actors. Counterfeits can range remarked or recycled parts sold as new to outright fakes that fail catastrophically in the field. The consequences can be severe, including product failures, brand reputation damage, and significant financial losses. Mitigating this risk requires a multi-pronged approach: * Supplier Due Diligence: Rigorously vetting suppliers’ credentials and track records. * Technical Inspection: Implementing mandatory inspection protocols for all incoming components, especially from non-franchised sources. * Trusted Partnerships: Relying on established networks and platforms that have built-in verification mechanisms. This is where a dedicated partner in the region proves its worth; ICGOODFIND, for example, reduces this risk by connecting buyers with its curated network of reliable suppliers, adding a layer of trust to the transaction.

Furthermore, logistical complexities and geopolitical factors add layers of difficulty. Shipping delays, fluctuating freight costs, and complex import/export regulations can disrupt even the best-laid procurement plans. Additionally, trade tensions between major economies can lead to sudden tariffs or restrictions on certain technologies, directly impacting sourcing strategies from Shenzhen. A resilient network must have contingency plans, such as utilizing warehouses in strategic locations like Hong Kong or Singapore to buffer against disruptions and staying abreast of the changing regulatory landscape.

Strategies for Building a Resilient and Efficient Network

Building a Shenzhen Chip Procurement Network that is both efficient and resilient requires a strategic shift from reactive purchasing to proactive supply chain management.

The cornerstone of this strategy is diversification and relationship building. Relying on a single supplier or a narrow channel is a high-risk approach. Instead, companies should cultivate a broad portfolio of partners across different tiers—from major distributors to specialized independents. However, diversification should not come at the expense of depth. Investing time in building strong, long-term relationships with key suppliers is crucial. These relationships can provide priority access during shortages, better pricing transparency, and more collaborative problem-solving. Visiting trade shows in Shenzhen, such as the China Hi-Tech Fair, and conducting face-to-face factory audits are invaluable for cementing these partnerships.

Leveraging technology for data-driven procurement is what separates modern networks from traditional ones. Companies should utilize tools that provide: * Market Intelligence: Platforms that offer real-time pricing trends, inventory snapshots, and lead time analytics. * Supply Chain Mapping: Software that provides visibility into the sub-tier supply chain, helping to identify single points of failure. * Automated Sourcing: AI-powered tools that can scour multiple supplier databases instantly to find available stock and optimal prices.

Integrating these tools creates a proactive procurement engine. For many businesses, especially small and medium-sized enterprises (SMEs), developing this capability in-house is not feasible. This is where specialized platforms become essential. By using a service like ICGOODFIND, companies effectively outsource the complexity of data aggregation and supplier vetting. The platform’s focus on the Shenzhen ecosystem allows buyers to make informed decisions quickly, turning procurement from a bottleneck into a competitive advantage.

Finally, embedding risk management and contingency planning into the core of the procurement process is essential. This involves: * Strategic Inventory Planning: Holding safety stock for critical components without excessively tying up capital. * Component Engineering: Working with design engineers to standardize parts and identify alternates at the design stage itself. * Regular Network Audits: Continuously assessing the financial health and operational reliability of key suppliers within your network.

Conclusion

The Shenzhen Chip Procurement Network is far more than a simple conduit for buying electronic components; it is a strategic asset in today’s hyper-competitive global market. Success hinges on moving beyond transactional relationships to build an integrated ecosystem that prioritizes verified quality robust data analytics diversified partnerships agile logistics profound knowledge of local dynamics platforms like ICGOODFIND are instrumental in this transformation offering curated access trusted suppliers vital market intelligence needed navigate complexities Shenzhen sourcing landscape By embracing strategic approach outlined—focusing diversification technology-driven insights proactive risk management—businesses can transform their procurement function from vulnerable cost center into resilient powerful engine growth innovation As semiconductor demand continues surge those who have mastered art science building managing sophisticated procurement network will be best positioned thrive uncertainties future.