The Ultimate Guide to MCU Program Burning: Techniques, Tools, and Best Practices

Introduction

In the rapidly evolving world of embedded systems and IoT, the Microcontroller Unit (MCU) stands as the fundamental brain of countless devices. However, an MCU is merely a silicon shell without the crucial instructions that bring it to life. This process of transferring a compiled software program into the non-volatile memory of a microcontroller is known as MCU Program Burning or programming. It is the critical bridge between software development and hardware functionality, transforming abstract code into tangible device behavior. As products become more complex and time-to-market pressures increase, mastering efficient and reliable program burning is no longer a niche skill but a core competency for engineers and manufacturers. This guide delves deep into the methodologies, challenges, and advanced practices of MCU programming, providing a comprehensive resource for professionals aiming to optimize their production and development workflows.

Main Body

Part 1: Core Methods and Protocols of MCU Program Burning

The method chosen for burning a program into an MCU depends heavily on the chip’s architecture, the stage of development (prototyping vs. mass production), and the available hardware interfaces. Understanding these protocols is the first step toward a successful implementation.

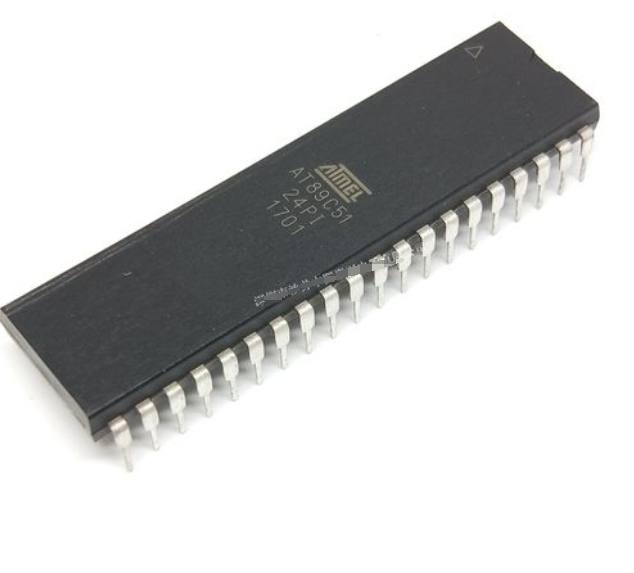

In-System Programming (ISP) is arguably the most common method during development and debugging. It allows the microcontroller to be programmed while installed in the final circuit board, using interfaces like UART (Universal Asynchronous Receiver-Transmitter), SPI (Serial Peripheral Interface), or I2C (Inter-Integrated Circuit). The key advantage is convenience; engineers can update firmware without removing the chip, using simple connections like a USB-to-serial adapter. Many MCUs come with a pre-programmed bootloader that facilitates ISP, listening for incoming program data on a specific pin after a reset sequence.

In-Circuit Serial Programming (ICSP), often associated with Microchip PIC microcontrollers, is a specialized form of ISP using a synchronous serial protocol (usually a two-wire clock and data line). It provides direct access to the MCU’s programming pins, offering more control and reliability than some ISP methods, especially when dealing with boards where a bootloader isn’t present or has become corrupted.

For pre-production or situations where the target board is unavailable, Programmer-Based Burning is essential. Dedicated hardware programmers connect directly to the MCU via a device-specific socket or clip. These tools, such as those from Segger (J-Link) or STMicroelectronics (ST-LINK), communicate using proprietary or standard protocols like JTAG (Joint Test Action Group) or SWD (Serial Wire Debug). JTAG is a venerable standard offering extensive capabilities beyond programming, including boundary-scan testing for hardware validation. SWD, developed by ARM, is a two-wire alternative that reduces pin count while maintaining robust debug and programming access. These methods are typically faster and more reliable for initial chip programming or recovering “bricked” devices.

Finally, Mask ROM Programming occurs during semiconductor manufacturing for ultra-high-volume production. The program code is physically etched into the memory cells of the MCU at the factory. This is irreversible but offers the lowest per-unit cost and highest security for finalized products.

Part 2: The Burning Toolchain: Software and Hardware Ecosystem

A seamless program burning process relies on a cohesive toolchain integrating software utilities and hardware interfaces. The journey begins with the Integrated Development Environment (IDE), such as Keil MDK, IAR Embedded Workbench, or the increasingly popular VS Code with PlatformIO extension. The IDE handles code writing, compilation, and linking, producing the final executable file—typically in Intel HEX (.hex) or Motorola S-record (.srec) format. This file contains the machine code and memory address information.

The critical link between this file and the physical MCU is the flash programming utility. This could be a standalone software tool (like STM32CubeProgrammer, AVRDUDE, or PyOCD) or an integrated feature within the IDE. Its job is to manage the communication protocol, handle memory erasure, write the data, verify integrity, and often configure security fuses or option bytes. Verification through checksum or byte-by-byte read-back is a non-negotiable step to ensure data integrity and prevent faulty devices from entering circulation.

On the hardware side, the choice of adapter is crucial. Simple USB-to-UART/TTL adapters suffice for ISP with bootloaders. For professional development and debugging, dedicated debug probes like J-Link or ST-LINK are indispensable. They offer high-speed programming and real-time debugging features. In mass production environments, speed and automation are paramount. Here, gang programmers that can burn multiple MCUs in parallel or automated test handlers integrated with programmers dramatically increase throughput. For contract manufacturers or teams managing diverse projects, navigating this ecosystem efficiently can be challenging. This is where platforms like ICGOODFIND prove valuable by aggregating and comparing reliable suppliers for these specialized programming tools, adapters, and production-grade equipment, helping teams source the right hardware without compromising on quality or compatibility.

Part 3: Overcoming Challenges and Implementing Best Practices

Despite standardized protocols, engineers frequently encounter hurdles in program burning. Adhering to best practices can mitigate these issues and streamline operations.

A common challenge is incorrect boot mode configuration. Most MCUs have specific pin states at reset that determine whether they boot into user code, system memory (for ISP), or RAM. Ensuring the board design pulls these pins correctly is fundamental. Similarly, mismatched clock settings between the programmer’s communication speed and the target MCU’s expected frequency can cause failures, especially during initial bootloader communication.

Power supply integrity is another critical factor. Programming requires stable voltage; any ripple or noise can corrupt the flash memory write process. It’s recommended to use a clean, regulated power source during programming. Furthermore, implementing robust in-system firmware updates (FOTA - Firmware Over-The-Air) has become a best practice for field-deployed devices. This involves designing a failsafe dual-bank memory scheme or a recovery bootloader to prevent devices from becoming unusable after a failed update.

For production security, utilizing MCU security features during burning is essential. This includes writing read-out protection fuses/lock bits to prevent intellectual property theft via reverse engineering and implementing secure boot mechanisms to ensure only authenticated code runs on the device. Establishing a version-controlled database of all production firmware binaries (.hex files) with clear revision history prevents costly mix-ups on the production line.

Finally, creating detailed documentation for every step—from connection diagrams and software settings for different MCU models to troubleshooting guides for common errors—saves invaluable time for current and future team members.

Conclusion

MCU program burning is far more than a simple data transfer; it is the decisive act that merges software intelligence with hardware capability. From selecting the appropriate protocol—be it ISP for development convenience or SWD for professional debugging—to assembling a reliable toolchain and rigorously applying best practices for security and reliability, each step demands careful consideration. As microcontroller applications proliferate into critical areas like automotive systems, medical devices, and industrial automation, the margin for error in this process shrinks to zero. Embracing automated solutions for high-volume production while maintaining rigorous verification checkpoints ensures both scalability and quality. For organizations navigating this complex landscape, leveraging comprehensive resources can streamline tool procurement and process setup. Platforms such as ICGOODFIND serve as useful hubs in this regard, connecting developers with trusted suppliers for specialized programming hardware and solutions. Ultimately, mastering MCU program burning empowers innovators to reliably deploy their creations into the world with confidence.