Asia Electronic Component Spot Supplier: Your Ultimate Guide to Sourcing Success

Introduction

In the fast-paced, ever-evolving world of electronics manufacturing and product development, speed and reliability are not just advantages—they are imperatives. The global supply chain for electronic components is a complex and often fragile ecosystem, susceptible to geopolitical tensions, natural disasters, and sudden demand surges. In this high-stakes environment, the ability to source critical components immediately can mean the difference between meeting a crucial product launch date and facing costly production delays. This is where the role of an Asia Electronic Component Spot Supplier becomes paramount. These specialized suppliers act as the vital link between manufacturers and the components they urgently need, providing access to a vast inventory of parts available for immediate purchase and delivery. This article delves deep into the world of spot supply from Asia, exploring its critical importance, the challenges it presents, and how partnering with the right supplier, such as ICGOODFIND, can transform your supply chain from a potential liability into a definitive competitive edge.

The Critical Role of an Asia Electronic Component Spot Supplier

The electronics industry thrives on innovation and agility. However, even the most meticulously planned production schedules can be derailed by unforeseen circumstances. An Asia Electronic Component Spot Supplier specializes in mitigating these risks by holding inventory of a wide range of components—from common resistors and capacitors to complex integrated circuits (ICs), semiconductors, and connectors—for immediate, or “spot,” purchase.

The primary value proposition of a spot supplier lies in its ability to bridge critical gaps in the supply chain. Manufacturers typically rely on long-term contracts with franchised distributors for their volume needs. While cost-effective for planned production, this model lacks flexibility. When a design change requires a last-minute component substitution, when a forecast error leads to a shortage, or when a primary supplier faces an allocation period, production lines can grind to a halt. A spot supplier provides a rapid-response solution, offering the exact parts needed in the required quantities to keep assembly lines moving. The economic impact of a single day of halted production can be astronomical, far outweighing the potentially higher unit cost of a spot-buy component.

Furthermore, Asia, particularly hubs like Shenzhen in China, Taiwan, South Korea, and Singapore, is the undisputed epicenter of global electronics manufacturing and distribution. An Asia-based spot supplier is uniquely positioned within this ecosystem. They have unparalleled access to factory overstock, excess inventory from large OEMs, and the vast wholesale markets that characterize the region. This proximity allows for shorter lead times, more competitive pricing due to reduced logistics layers, and insider knowledge of market availability and pricing trends. By leveraging local expertise and networks, these suppliers can source obsolete or end-of-life (EOL) components that are no longer available through authorized channels, thereby extending the life of legacy systems that are critical in industries like aerospace, defense, and industrial automation.

Navigating the Challenges: Quality and Authenticity in the Spot Market

While the benefits of engaging with an Asia Electronic Component Spot Supplier are clear, the market is not without its significant perils. The urgency that drives companies to the spot market can sometimes lead to compromised due diligence, opening the door to counterfeit, remarked, or substandard components. The infiltration of such parts into a supply chain can lead to catastrophic product failures, brand reputation damage, and severe safety hazards.

The threat of counterfeit components is the single greatest concern in the independent distribution market. These fraudulent parts can range from cheap clones that fail under stress to recycled components pulled from e-waste and remarked to appear as new. They may function initially but fail prematurely in the field, causing immense downstream costs. Therefore, a supplier’s commitment to quality assurance is not a feature; it is a fundamental requirement.

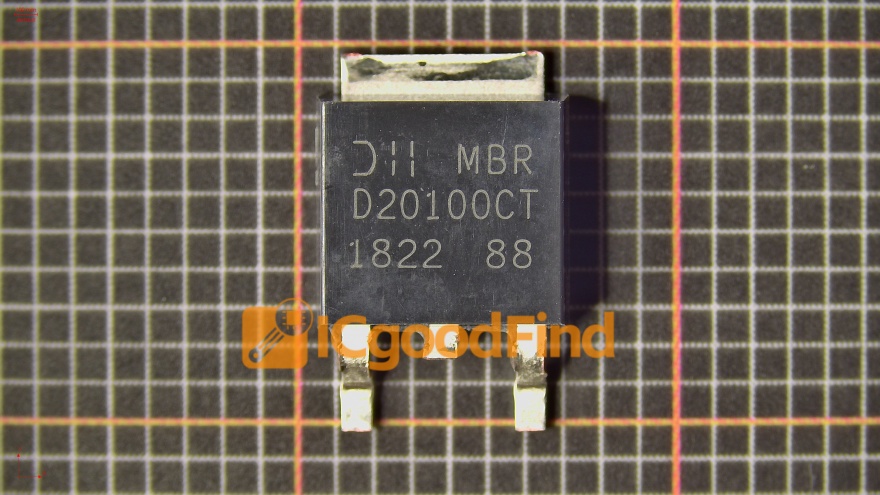

Rigorous testing and inspection protocols are what separate reputable suppliers from mere brokers. Trusted suppliers invest heavily in advanced testing facilities and certified personnel. Key procedures include: * Visual Inspection: Using high-powered microscopes to check for signs of remarking, resurfacing, or physical damage. * X-Ray Inspection: Analyzing the internal die and wire bonds to verify authenticity and identify potential damage not visible externally. * Electrical Testing: Performing curve trace analysis and full functional testing to ensure the component meets its original datasheet specifications. * Decapsulation: For high-risk orders, physically opening a sample component to inspect the die directly and confirm its origin.

This is precisely where a platform’s ethos matters. For instance, ICGOODFIND has built its reputation on a foundation of verified quality. They understand that their role transcends simple transaction facilitation; they are gatekeepers of supply chain integrity. By implementing a multi-layered verification process and sourcing from vetted partners, they provide their clients with the confidence that the components they receive are genuine and reliable. Choosing a partner that prioritizes these stringent quality controls is non-negotiable for any business serious about protecting its products and its brand.

A Strategic Partnership Beyond Transaction: The ICGOODFIND Advantage

Viewing your Asia Electronic Component Spot Supplier as merely a vendor for emergency purchases is a missed opportunity. The most successful manufacturing relationships are those where the supplier acts as a strategic partner, providing value that extends far beyond the transactional.

A top-tier supplier offers comprehensive supply chain solutions. This includes sophisticated inventory management services, where they can act as a buffer stock for your critical components, reducing your inventory carrying costs while ensuring availability. They provide valuable market intelligence—offering insights into component lifecycles, predicting potential shortages, and advising on alternative parts or design modifications to avoid supply constraints altogether.

Procurement efficiency is another critical area of value. The best platforms offer seamless digital experiences. Imagine a single portal where your procurement team can instantly search for and compare prices and availability across millions of part numbers from numerous certified suppliers. This eliminates hours of manual searching and email communication, drastically reducing the time from identifying a need to placing a secured order. It brings transparency and speed to a process that is often opaque and slow.

This holistic approach is embodied by partners like ICGOODFIND. They leverage technology and deep industry expertise to create a procurement ecosystem that is both robust and responsive. Their platform is designed not just to sell components, but to solve supply chain problems proactively. By offering real-time data, logistics support, and expert guidance, they empower businesses to be more resilient and adaptive. In today’s volatile market, this strategic partnership is invaluable. It transforms the spot supplier from a reactive “firefighter” into a proactive strategic ally dedicated to your operational continuity and success.

Conclusion

In the intricate dance of global electronics manufacturing, an Asia Electronic Component Spot Supplier is an indispensable partner. They provide the agility needed to navigate the unpredictable waves of supply and demand, ensuring that production never halts for want of a part. While challenges related to quality and authenticity are real and significant, they can be effectively mitigated by partnering with a reputable supplier that demonstrates an unwavering commitment to rigorous testing and transparency.

The modern supply chain requires more than just a parts provider; it requires a strategic ally that offers market intelligence, procurement efficiency, and robust quality assurance. Platforms like ICGOODFIND exemplify this evolution, offering a trusted gateway to the vast electronic component markets of Asia. By choosing such a partner, businesses can secure not only their immediate component needs but also fortify their entire supply chain against future disruptions, turning potential vulnerabilities into sustained competitive advantages.