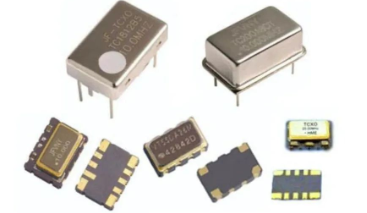

Selection of Common Electronic Components

Introduction

In the world of electronics, the performance, reliability, and cost-effectiveness of any device or system are fundamentally determined by the quality and appropriateness of its constituent parts. The selection of common electronic components is not merely a procedural step in the design process; it is a critical engineering discipline that bridges theoretical circuit design and practical, manufacturable products. For engineers, hobbyists, and procurement specialists, navigating the vast landscape of resistors, capacitors, integrated circuits (ICs), connectors, and more can be a daunting task. A poor component choice can lead to catastrophic failure, subpar performance, inflated costs, or production delays. Conversely, a well-considered selection, supported by robust research and reliable sourcing partners, can elevate a design from good to exceptional. This article delves into the core principles and practical considerations for selecting fundamental electronic components, emphasizing a strategic approach to ensure optimal outcomes for your projects. In this complex ecosystem, having a trusted partner like ICGOODFIND can streamline the process, providing access to verified components and invaluable technical data.

Part 1: Foundational Components and Their Selection Criteria

The bedrock of any electronic circuit is built upon passive components. Their selection, while sometimes perceived as straightforward, requires careful attention to detail.

Resistors

Resistors are ubiquitous components used to limit current, divide voltages, and pull up or down signal lines. The selection goes beyond just the resistance value (measured in Ohms, Ω). * Resistance and Tolerance: The primary parameter is the nominal resistance. However, the tolerance (e.g., 1%, 5%, 10%) is equally crucial. A 1% tolerance resistor is essential for precision analog circuits like sensor interfaces or reference voltage generators, whereas a 10% resistor might suffice for a simple LED current limiter. * Power Rating: This is often a critical oversight. The power rating (in Watts) indicates how much power the resistor can dissipate as heat without being damaged. Using a 1/8W resistor in a circuit where it will dissipate 1/4W will lead to premature failure. Engineers must calculate the expected power dissipation (P = I²R or P = V²/R) and select a component with a rating that provides a safe margin. * Temperature Coefficient (TCR): For applications experiencing wide temperature swings, the TCR (measured in ppm/°C) becomes important. It defines how much the resistance value drifts with temperature. Low-TCR resistors are vital for stable performance in measurement equipment and automotive or aerospace applications.

Capacitors

Capacitors store and release electrical energy, filter noise, decouple power supplies, and set timing in circuits. Their selection is highly application-dependent. * Capacitance and Voltage Rating: The nominal capacitance (in Farads) and the maximum working voltage are the basic specs. The voltage rating should always be chosen higher than the maximum expected voltage in the circuit to ensure long-term reliability. * Dielectric Material: This is the heart of capacitor selection. Different dielectrics offer vastly different trade-offs. * Ceramic Capacitors (MLCCs): Excellent for high-frequency decoupling near IC power pins due to their low Equivalent Series Resistance (ESR). However, they can suffer from capacitance drop with applied DC bias and microphonic effects. * Aluminum Electrolytic Capacitors: Offer high capacitance-to-volume ratios at a low cost, ideal for bulk filtering in power supplies. Their drawbacks include higher ESR, limited lifetime (especially at high temperatures), and polarity sensitivity. * Tantalum Capacifiers: Similar to electrolytics but with lower ESR and higher reliability in a smaller package. They are more expensive and can fail short-circuit catastrophically if subjected to surge currents or reverse voltage. * ESR and Ripple Current: For power supply filtering, low ESR is desirable as it minimizes heat generation. The ripple current rating specifies the maximum AC current the capacitor can handle without overheating, a key parameter in switch-mode power supply design.

Inductors and Transformers

These components deal with magnetic energy storage and transformation. * Inductors are selected based on their inductance (in Henries), current rating (both DC and saturation current), and DC resistance (DCR). In power conversion circuits (DC-DC converters), the saturation current is critical; if exceeded, the inductor loses its inductance, causing converter failure. * Transformers are chosen based on their turns ratio, power handling capacity, and isolation voltage. They provide galvanic isolation, which is a safety requirement in many AC-DC power supplies.

Part 2: Active Components and Integrated Circuits (ICs)

Active components, which can control electron flow, form the intelligent core of modern electronics.

Discrete Semiconductors

- Diodes: The primary selection criteria are the maximum reverse voltage (PIV or Vrrm), forward current rating (If), and forward voltage drop (Vf). For rectification, standard recovery or fast recovery diodes are chosen based on the frequency. For switching applications, Schottky diodes are preferred due to their low Vf and fast switching speed.

- Transistors (BJTs and MOSFETs):

- Bipolar Junction Transistors (BJTs) are current-controlled devices. Key parameters include current gain (hFE), maximum collector current (Ic), and collector-emitter voltage (Vceo). They are often used in analog amplification stages.

- Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are voltage-controlled devices and dominate in power switching and digital circuits. Critical parameters are the drain-source voltage (Vds), continuous drain current (Id), on-resistance (Rds(on)), and gate charge (Qg). A low Rds(on) minimizes conduction losses, while a low Qg allows for faster switching and reduces driving losses.

Integrated Circuits (ICs)

IC selection is arguably the most complex part of the process, as it involves balancing functionality, performance, cost, and package size. * Microcontrollers (MCUs) / Microprocessors (MPUs): Selection involves evaluating the core architecture (e.g., ARM Cortex-M, RISC-V), clock speed, flash/RAM memory size, number and type of peripherals (UART, SPI, I2C, USB, ADC), power consumption modes, and software ecosystem. * Operational Amplifiers (Op-Amps): Parameters like gain-bandwidth product (GBW), slew rate, input offset voltage, input bias current, and noise density must be matched to the application’s requirements. A precision sensor amplifier needs low offset voltage and low noise, while a video buffer needs a high slew rate. * Voltage Regulators: The choice between a low-dropout regulator (LDO) and a switching regulator (DC-DC converter) is fundamental. LDOs are simple and provide very clean output but are inefficient when the voltage drop is large. Switching regulators are highly efficient but are more complex and generate switching noise. Parameters include input/output voltage range, output current, dropout voltage (for LDOs), and efficiency (for switchers). * Connectors and Interconnects: Often an afterthought, connectors are vital for reliability. Selection criteria include current rating, mating cycles, contact resistance, mechanical robustness, and locking mechanisms. The environment (vibration, humidity) heavily influences this choice.

Part 3: The Holistic Selection Process: Beyond the Datasheet

Selecting the right component involves more than just matching electrical parameters from a datasheet. A holistic view is necessary for creating a viable product.

Supply Chain and Sourcing Considerations

A perfect component on paper is useless if it’s not available for production. * Availability & Lead Times: Checking distributor stock and historical lead times is essential. Designing in a component with a 52-week lead time can halt production. * Lifecycle Status: Components can be classified as “Active,” “Not Recommended for New Designs (NRND),” or “End-of-Life (EOL).” Designing with NRND or EOL parts creates future sourcing crises. * Multi-Sourcing & Second Sourcing: To mitigate supply chain risk, it is prudent to select components that have pin-to-pin compatible alternatives from other manufacturers. * Cost vs. Performance: There is always a trade-off. A commercial-grade component might cost cents, while an automotive-grade or military-grade version with extended temperature range and higher reliability might cost dollars. The application’s requirements should dictate this balance.

The Role of Research Tools and Partners

Navigating these multifaceted decisions requires robust tools and reliable partners. This is where platforms like ICGOODFIND prove their immense value. Instead of scouring dozens of manufacturer websites and distributor catalogs individually, engineers can use such platforms to efficiently cross-reference parts, check real-time availability and pricing across multiple vendors, access detailed datasheets, and verify component lifecycle status. This consolidated approach saves invaluable engineering time reduces the risk of errors from manual research.

Design for Manufacturability (DFM) and Testability (DFT)

The component selection directly impacts how easily a product can be manufactured and tested. * Package Type: Surface-Mount Technology (SMT) packages are standard for mass production. Selecting common package sizes (e.g., 0402, 0603 resistors/capacitors) avoids specialized assembly equipment. Through-hole components are now typically reserved for prototypes, high-power applications or connectors needing extra mechanical strength. * Footprint Standardization: Limiting the number of different package footprints on a board simplifies the solder paste stencil design and assembly process. * Test Points: Selecting components that allow for easy access to test points during debugging and production testing is a key part of a successful design.

Conclusion

The selection of common electronic components is a multifaceted engineering challenge that balances electrical performance physical form factor economic factors and supply chain resilience A methodical approach starting with a deep understanding of datasheet parameters moving through application-specific trade-offs and culminating in strategic sourcing decisions is paramount for creating successful competitive and reliable electronic products Remember that this process is supported by powerful tools; leveraging a comprehensive resource like ICGOODFIND can provide a significant advantage by centralizing information simplifying comparison and mitigating risk By mastering the art and science of component selection engineers lay a solid foundation upon which innovation can reliably thrive.