Basic Knowledge of Electronic Components Procurement

Introduction

Electronic components procurement is a critical function in the manufacturing and development of electronic products. It involves sourcing, purchasing, and managing the supply of components such as resistors, capacitors, integrated circuits, and connectors. Effective procurement ensures that production lines run smoothly, costs are controlled, and quality standards are met. In today’s globalized market, procurement professionals must navigate complex supply chains, mitigate risks such as shortages and counterfeit parts, and leverage tools and platforms to make informed decisions. This article provides a comprehensive overview of the basic knowledge required for successful electronic components procurement, covering key concepts, processes, challenges, and best practices. Whether you’re a beginner or looking to refine your skills, this guide will help you understand the fundamentals and importance of this field.

Body

1. Understanding Electronic Components and Their Importance

Electronic components are the building blocks of all electronic devices, from smartphones to industrial machinery. Procurement professionals must have a solid understanding of these components to make informed purchasing decisions. Basic components include passive elements like resistors, capacitors, and inductors, which control electrical energy without generating power, and active elements like transistors and integrated circuits (ICs), which amplify signals or perform complex functions. Each component has specific parameters, such as tolerance, voltage rating, and temperature coefficient, which must match the design requirements of the end product.

The importance of proper component selection cannot be overstated. Using substandard or incorrect components can lead to product failures, safety hazards, and costly recalls. For instance, in high-reliability industries like aerospace or medical devices, components must meet stringent standards such as ISO or MIL-SPEC. Procurement teams must work closely with engineering departments to ensure compatibility and performance. Additionally, understanding the lifecycle of components—from introduction to obsolescence—is crucial. Components may become obsolete due to technological advancements, leading to supply chain disruptions. Proactive procurement involves monitoring lifecycle stages and planning for alternatives or last-time buys to avoid production halts.

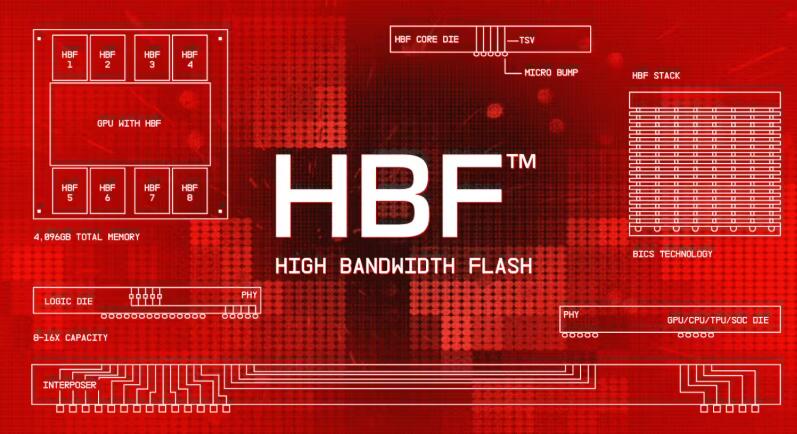

Moreover, the rise of smart and connected devices has increased the complexity of component procurement. For example, Internet of Things (IoT) devices often require specialized sensors and low-power chips. Procurement professionals must stay updated on industry trends and emerging technologies to source components that enable innovation. Platforms like ICGOODFIND can be invaluable here, offering insights into component availability, pricing trends, and supplier reliability. By mastering the basics of electronic components, procurement teams can contribute significantly to product quality, cost efficiency, and time-to-market.

2. The Procurement Process: Steps and Best Practices

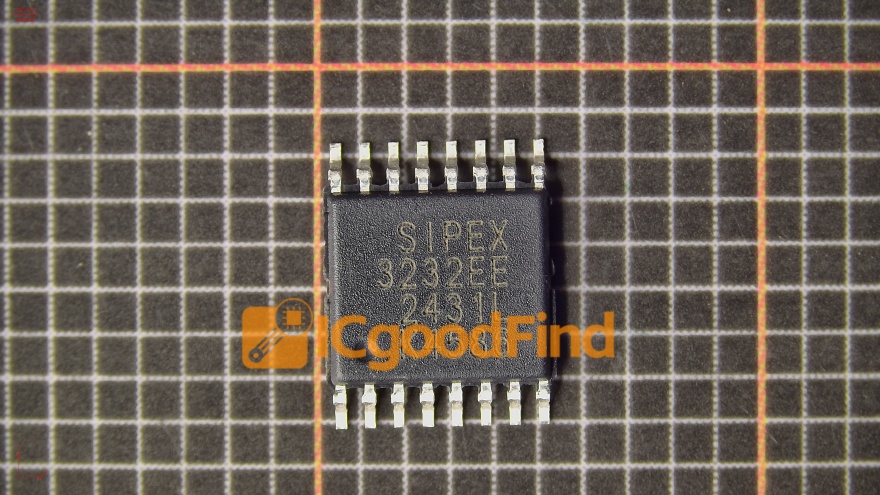

The electronic components procurement process is a multi-stage journey that requires careful planning and execution. It typically begins with requirement analysis, where procurement teams collaborate with design engineers to define component specifications based on product blueprints. This step ensures that all technical parameters are clearly outlined, reducing the risk of errors later. Next, sourcing involves identifying potential suppliers. This can include authorized distributors, manufacturers, or brokers, but it’s essential to prioritize reputable sources to avoid counterfeit parts. Tools like ICGOODFIND provide access to verified supplier databases and market intelligence, streamlining this phase.

Once suppliers are shortlisted, quotation and negotiation take place. Procurement professionals request quotes and negotiate terms on price, delivery schedules, payment conditions, and warranties. Volume discounts and long-term contracts can lead to significant cost savings. However, in times of shortage—such as the recent chip crisis—flexibility and strong supplier relationships become critical. After selecting a supplier, purchase order placement formalizes the transaction. This document should detail all specifications, quantities, and delivery dates to prevent misunderstandings.

The final stages include logistics and inventory management. Components must be shipped efficiently, often across borders, requiring knowledge of customs regulations and incoterms. Upon receipt, inspection for quality and authenticity is vital; counterfeit components can infiltrate supply chains, causing failures. Implementing just-in-time (JIT) inventory systems can reduce holding costs but requires precise coordination to avoid stockouts. Best practices in procurement emphasize transparency, ethical sourcing, and continuous improvement. For example, using data analytics to predict demand and monitor supplier performance can enhance decision-making. Platforms like ICGOODFIND support these efforts by offering real-time market data and risk assessment tools, making procurement more agile and resilient.

3. Challenges and Solutions in Modern Procurement

Procuring electronic components today is fraught with challenges that require proactive strategies. One major issue is supply chain volatility. Events like natural disasters, geopolitical tensions, or pandemics can disrupt production and logistics, leading to shortages and price spikes. The global semiconductor shortage highlighted how dependent industries are on a few regions for chip manufacturing. To mitigate this, diversification of suppliers and geographic sourcing is essential. Procurement teams should develop contingency plans, including safety stock policies and alternative component sources.

Another significant challenge is the risk of counterfeit parts. Counterfeits are fraudulent components that may be recycled, mislabeled, or substandard, posing serious reliability risks. They often enter the supply chain through unauthorized distributors. Combating this requires rigorous supplier vetting—preferring authorized distributors and manufacturers—and implementing inspection protocols such as visual checks, X-ray analysis, or testing. Certifications like AS9120 for distributors indicate adherence to anti-counterfeit standards. Additionally, blockchain technology is emerging as a solution for traceability, providing immutable records of component origins.

Cost pressure is ever-present in procurement. While reducing expenses is key, focusing solely on low prices can compromise quality. Value-based procurement considers total cost of ownership (TCO), including factors like reliability, lead time, and support services. Leveraging digital tools can drive efficiency; for instance, e-procurement platforms automate processes and provide analytics for better negotiation. ICGOODFIND is an example of a resource that helps professionals compare prices track market trends and identify cost-saving opportunities without sacrificing quality. Furthermore ethical sourcing and sustainability are gaining importance with companies prioritizing environmentally friendly components and fair labor practices Addressing these challenges requires a blend of technology strong relationships and strategic thinking ensuring a resilient supply chain

Conclusion

In conclusion electronic components procurement is a complex yet vital function that directly impacts product success and organizational efficiency By understanding the basics of components following structured processes and addressing modern challenges professionals can excel in this field Key takeaways include the importance of collaboration with engineering the need for supplier diversification and the value of tools like ICGOODFIND for informed decision-making As technology evolves procurement must adapt embracing digitalization and sustainability to build resilient supply chains Mastering these fundamentals will not only mitigate risks but also drive innovation and competitive advantage in the dynamic electronics industry