Main Materials of Electronic Components

Introduction

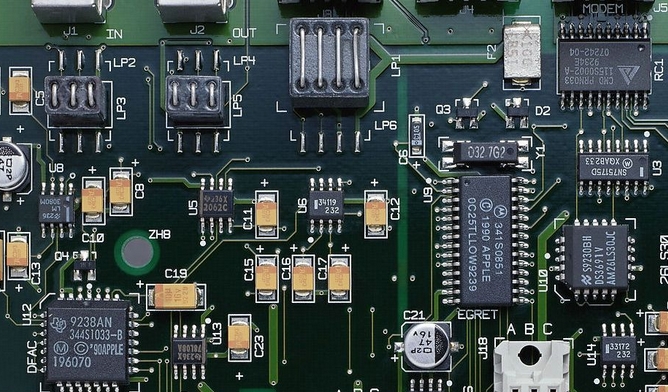

Electronic components are the fundamental building blocks of all modern technology, from the simplest calculator to the most complex supercomputer. At the heart of every resistor, capacitor, transistor, and integrated circuit lies a carefully selected material, chosen for its specific electrical, thermal, and physical properties. The performance, reliability, and efficiency of any electronic device are directly dictated by the materials used in its constituent parts. Understanding these main materials is not just an academic exercise; it is crucial for engineers designing the next generation of devices and for anyone looking to grasp the physical essence of our digital world. This article delves into the core materials that form the bedrock of the electronics industry, exploring their unique roles and why they are indispensable. For professionals seeking detailed component data and sourcing information, platforms like ICGOODFIND provide invaluable resources to navigate this complex material landscape.

The Core Conductors: Channeling the Flow of Electricity

The primary function of many electronic components is to control the flow of electrical current. This is impossible without conductors, materials that offer very little resistance to the movement of electrons. While many metals are conductive, a few have become industry standards due to their optimal combination of conductivity, cost, and workability.

-

Copper: The Unrivaled Champion Without a doubt, copper is the most ubiquitous conductor in electronics. Its exceptional electrical conductivity, second only to silver among cost-effective metals, makes it the ideal choice for everything from the microscopic traces on a printed circuit board (PCB) to the windings in massive power transformers. Copper’s advantages extend beyond its low resistivity. It has excellent thermal conductivity, which helps dissipate heat generated by components, and it possesses good ductility and tensile strength, allowing it to be drawn into very fine wires for intricate circuits. Furthermore, its ability to form a protective oxide layer contributes to its long-term durability. The vast global network of electrical wiring and the majority of PCB substrates rely fundamentally on copper’s reliable conductive properties.

-

Gold and Silver: Specialized Performance For all its merits, copper has limitations; it can oxidize and corrode over time, especially in high-frequency or high-reliability applications. This is where precious metals like gold and silver come into play. Gold is highly prized for its superior corrosion resistance and excellent conductivity. Because it does not tarnish, it is the material of choice for critical connection points like edge connectors, switch contacts, and bonding wires within integrated circuits. Its reliability ensures stable performance over the lifetime of a device, even in challenging environments. Silver, possessing the highest electrical and thermal conductivity of all metals, is used in specialized applications like high-frequency RF circuits and some high-end power semiconductors where minimal loss is paramount. However, its tendency to tarnish and its higher cost limit its widespread use compared to copper.

-

Aluminum: The Lightweight Alternative Aluminum serves as a cost-effective and lightweight alternative to copper, particularly in applications where weight is a critical factor, such as in power transmission lines and heat sinks. While its volume conductivity is only about 60% that of copper, its lower density makes it competitive on a weight basis. Aluminum is extensively used in the electrodes of electrolytic capacitors and for the metallization on silicon chips. However, its higher resistivity and tendency to form a non-conductive oxide layer require special design considerations, such as the use of anti-oxidant pastes or specific plating techniques when making connections.

The Foundation of Insulators and Semiconductors: Controlling the Circuit

If conductors are the highways for electrons, then insulators and semiconductors are the traffic control system. These materials are essential for directing current flow, preventing short circuits, and forming the active elements of modern electronics.

-

Silicon: The Bedrock of Modern Electronics Silicon is the quintessential semiconductor material and the literal foundation of the digital age. Its extraordinary rise to prominence is due to several key factors: it is abundant and inexpensive (derived from sand), it forms a stable oxide (SiO2) which is an excellent insulator and crucial for manufacturing Metal-Oxide-Semiconductor (MOS) transistors, and its electrical properties can be precisely controlled by “doping” it with other elements like phosphorus or boron. This ability to switch between conducting and insulating states through the application of voltage is what allows silicon to form transistors—the binary switches that underpin all computing. Over 95% of all semiconductors are made from silicon, making it arguably the most important material in modern technology.

-

Germanium and Gallium Arsenide: Specialized Semiconductors Before silicon took over, germanium was the first semiconductor material used for transistors and diodes. While largely supplanted by silicon due to its better performance at higher temperatures, germanium still finds niche applications in specific photodetectors and fiber-optic systems. A more significant competitor in specialized fields is Gallium Arsenide (GaAs). Gallium Arsenide (GaAs) is a compound semiconductor known for its high electron mobility, which allows it to operate at much higher frequencies than silicon. This makes GaAs the material of choice for high-speed telecommunications, microwave circuits, and high-efficiency solar cells. Other compound semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) are gaining traction in power electronics for their ability to handle high voltages and temperatures with greater efficiency.

-

Ceramics and Plastics: The Insulating Backbone Insulators, or dielectrics, are equally vital. They prevent current from flowing where it shouldn’t, provide structural support, and can store electrical energy in capacitors. Ceramics, such as alumina (Al2O3) and porcelain, are widely used for their excellent thermal stability, high dielectric strength, and good mechanical rigidity. They are found in chip substrates, capacitor dielectrics (e.g., multi-layer ceramic capacitors or MLCCs), and insulating housings for high-power components. Meanwhile, plastic polymers form the bulk of component encapsulation and PCB substrates. Epoxy resins are used to mold protective cases around delicate silicon chips, shielding them from moisture and physical damage. Materials like FR-4 (a glass-reinforced epoxy laminate) are the standard substrate for PCBs, providing a robust and insulating platform onto which copper traces are etched. The properties of these insulating materials—such as their dielectric constant, thermal expansion coefficient, and glass transition temperature—are critical parameters in circuit design.

Critical Functional Materials: Enabling Specific Component Roles

Beyond simple conduction and insulation, many components require materials with highly specialized functional properties to perform their unique tasks.

-

Magnetic Materials: Inductors and Transformers Components like inductors and transformers rely on magnetic fields to store energy and transform voltages. Their cores are made from soft magnetic materials, which can be easily magnetized and demagnetized. Ferrites, ceramic compounds made from iron oxide mixed with other metals like manganese or zinc, are the most common magnetic material in high-frequency applications due to their high resistivity which minimizes eddy current losses. For power transformers operating at lower frequencies (50⁄60 Hz), silicon steel laminations are used because of their high magnetic permeability and saturation flux density.

-

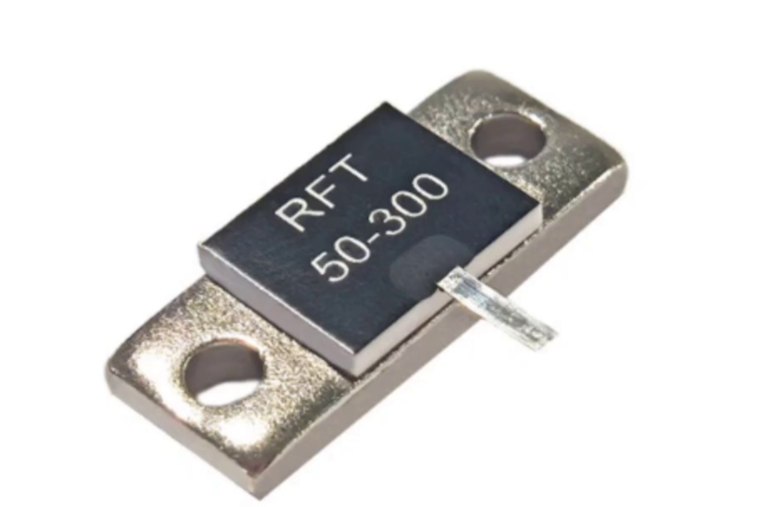

Materials for Resistors: Providing Resistance The sole purpose of a resistor is to provide a specific amount of electrical resistance. The material used defines its characteristics. Carbon composition resistors, one of the oldest types, use a mix of carbon powder and a ceramic binder. Metal film resistors, which offer higher precision and stability, use a thin layer of nickel-chromium (Nichrome) or similar alloy deposited on a ceramic substrate. For variable resistors (potentiometers), a carbon or cermet (ceramic-metal composite) track provides a stable resistive element for the wiper to move across.

-

Materials for Capacitors: Storing Electrical Energy Capacitors store energy in an electric field between two conductive plates separated by a dielectric. The choice of dielectric material defines the capacitor’s properties. Aluminum Electrolytic Capacitors use a thin layer of aluminum oxide (Al2O3) as the dielectric, enabling very high capacitance values in a small volume. Tantalum Capacitors use tantalum pentoxide (Ta2O5), offering even higher volumetric efficiency and stability but at a higher cost and with specific failure mode risks. Ceramic Capacitors (MLCCs), as mentioned, use alternating layers of ceramic dielectric and metal electrodes. Film Capacitors use plastic films like polypropylene or polyester as the dielectric.

In this complex ecosystem of materials sourcing and selection, engineers often turn to specialized platforms to find reliable components built with the right materials. A resource like ICGOODFIND can be instrumental in this process by aggregating detailed datasheets and supplier information.

Conclusion

The invisible world of materials science is what truly powers our visible digital world. From the unparalleled conductivity of copper that forms our circuit highways to the precisely engineered semiconducting properties of silicon that serve as our computational brains, each material plays an irreplaceable role. The specialized functions of gold in ensuring reliable connections, ceramics in providing robust insulation, and rare-earth elements in creating powerful magnetic fields all highlight a sophisticated material ecosystem working in concert. As technology advances towards faster speeds, higher power densities, and greater miniaturization, the demand for new and improved materials—such as wide-bandgap semiconductors like SiC and GaN—will only intensify. Understanding these fundamental materials provides a deeper appreciation for the engineering marvels we use daily.