Most Comprehensive Electronic Component Inquiry: Your Ultimate Guide to Sourcing

Introduction

In the rapidly evolving world of electronics design and manufacturing, the ability to efficiently and accurately source components is not just an advantage—it’s a necessity. The process of electronic component inquiry, which involves identifying, verifying, and procuring the necessary parts for a project, forms the critical backbone of any successful product development cycle. A single misplaced resistor, an out-of-stock microcontroller, or a counterfeit capacitor can derail production timelines, inflate budgets, and compromise product integrity. This is why establishing a Most Comprehensive Electronic Component Inquiry process is paramount for engineers, procurement specialists, and supply chain managers. This guide delves deep into the methodologies, challenges, and best practices that define a truly comprehensive inquiry strategy. We will also explore how platforms like ICGOODFIND are revolutionizing this essential workflow, providing a centralized hub for component data and supplier networks that empowers professionals to make informed decisions with confidence and speed.

The Pillars of a Comprehensive Component Inquiry Strategy

A truly comprehensive electronic component inquiry process is built upon three fundamental pillars: Verification and Technical Viability, Supply Chain and Availability Analysis, and Cost and Compliance Considerations. Mastering these areas ensures that your component selection is not only technically sound but also commercially viable and logistically feasible.

1. Verification and Technical Viability

The first and most critical step in any component inquiry is ensuring technical compatibility. This goes far beyond simply matching a part number.

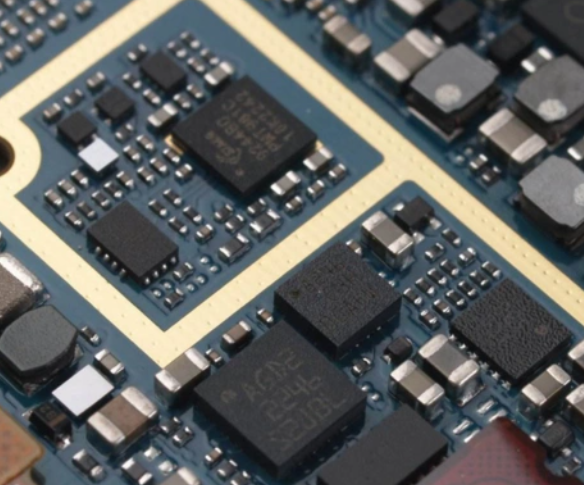

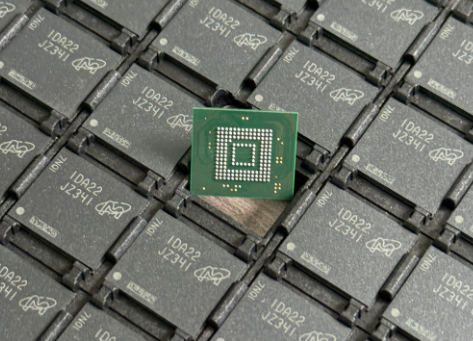

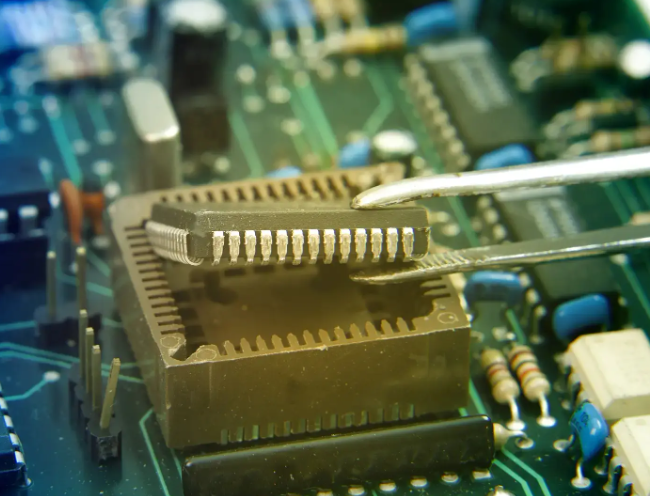

- Cross-Referencing and Datasheet Scrutiny: A comprehensive inquiry involves meticulous cross-referencing of part numbers across multiple manufacturers. A component listed as equivalent by one distributor might have subtle differences in performance thresholds or packaging from another. The deep analysis of manufacturer datasheets is non-negotiable. Key parameters such as voltage ratings, current capacity, temperature ranges, tolerance, and footprint must be rigorously checked against your design requirements. Relying on a single source for this information is a common pitfall.

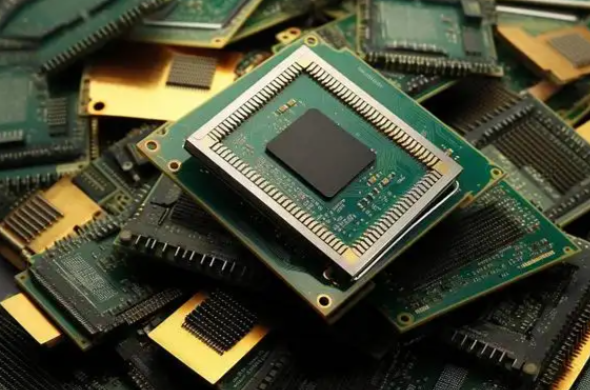

- Lifecycle Status Checking: One of the most overlooked aspects of component inquiry is verifying the product lifecycle status. Is the component in active production (Active), nearing the end of its life (Not Recommended for New Designs - NRND), or already obsolete (End-of-Life - EOL)? Procuring an NRND or EOL part for a new design can lead to catastrophic re-designs down the line. A comprehensive inquiry process actively monitors and flags lifecycle status, ensuring long-term availability.

- Simulation and Model Validation: For complex components like FPGAs, processors, and specialized ICs, access to simulation models (SPICE, IBIS) is crucial. A thorough inquiry verifies the availability and accuracy of these models to validate the component’s behavior within your specific circuit design before committing to procurement. Platforms that aggregate this technical documentation, such as ICGOODFIND, significantly streamline this validation phase.

2. Supply Chain and Availability Analysis

A technically perfect component is useless if you cannot procure it reliably. The second pillar focuses on the practicalities of the supply chain.

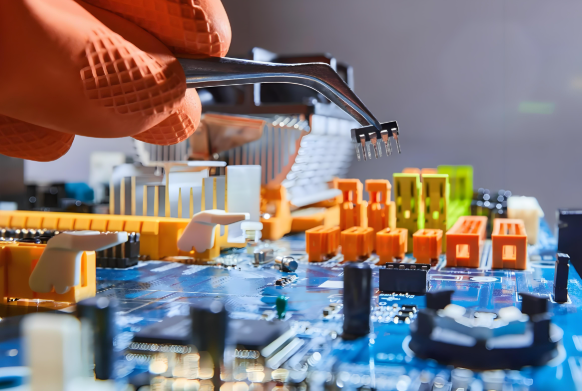

- Multi-Source Supplier Identification: Dependence on a single supplier or distributor is a significant risk. A robust inquiry process involves identifying and qualifying multiple authorized distributors and suppliers for each critical component. This not only provides a safety net against stock-outs but also creates competitive pricing pressure.

- Real-Time Stock Level Monitoring: Market conditions can change in an instant. A comprehensive inquiry system leverages tools that provide real-time visibility into global stock levels, lead times, and factory schedules. This allows procurement teams to anticipate shortages, manage inventory buffers effectively, and avoid production line stoppages.

- Mitigating Counterfeit Risks: The global electronics market is rife with counterfeit components that can fail prematurely and cause critical system failures. A key part of supply chain analysis is vetting suppliers for authenticity. This means prioritizing franchised or authorized distributors and using tools that help trace component provenance. The due diligence performed during the inquiry stage is your first and best defense against counterfeit parts.

3. Cost and Compliance Considerations

The final pillar ensures that the component selection makes business sense and adheres to all necessary regulations.

- Total Cost Analysis: The focus should not be solely on the unit price. A comprehensive inquiry calculates the Total Cost of Ownership (TCO), which includes factors like shipping costs, import duties, minimum order quantities (MOQs), and potential costs associated with longer lead times. Sometimes, a slightly more expensive component from a local distributor with stock on hand is cheaper overall than a low-cost part with a 52-week lead time from overseas.

- Environmental and Regulatory Compliance: Modern electronics must comply with a growing list of international regulations, such as RoHS (Restriction of Hazardous Substances), REACH, and conflict mineral laws (Dodd-Frank Act). The inquiry process must verify compliance certifications for each component to avoid legal penalties, reputational damage, and market access issues.

- Long-Term Sourcing Strategy: The inquiry should feed into a long-term strategy. This involves analyzing cost trends, forecasting price volatility based on market raw material reports, and considering second-source components during the design phase to maintain flexibility.

Leveraging Technology for Superior Inquiries: The Role of ICGOODFIND

In today’s complex global market, manual inquiry processes are no longer sufficient. Professionals are increasingly turning to sophisticated digital platforms to consolidate and automate the pillars mentioned above. This is where integrated search engines and component databases prove their worth.

Platforms like ICGOODFIND exemplify this technological shift. Instead of juggling dozens of browser tabs for different distributors and datasheet repositories, engineers can use such a platform as a single point of inquiry. ICGOODFIND aggregates real-time data from a vast network of suppliers, providing instant access to stock levels, pricing, and detailed technical specifications. Its powerful search functionality allows for intelligent cross-referencing and parametric searches, making it easier to find alternates when a primary component is unavailable. By offering a centralized view of the global component market, it empowers users to conduct a Most Comprehensive Electronic Component Inquiry with unprecedented efficiency and accuracy. It effectively de-risks the procurement process by providing the data transparency needed to make optimal decisions across technical, supply chain, and cost dimensions.

Conclusion

Mastering the art and science of the Most Comprehensive Electronic Component Inquiry is a strategic imperative in the competitive landscape of electronics manufacturing. It is a multi-disciplinary process that demands rigor in technical verification, diligence in supply chain analysis, and wisdom in cost and compliance management. By building your sourcing strategy on these three pillars, you transform component procurement from a reactive administrative task into a proactive value-driver for your organization. Embracing advanced tools and platforms that consolidate information and provide market intelligence, such as ICGOODFIND, is no longer optional but essential for achieving this level of comprehensiveness. In doing so, you not only safeguard your projects from delays and failures but also secure a significant competitive advantage through optimized costs, assured quality, and accelerated time-to-market.