The Ultimate Guide to Electronic Components Management System

Introduction

In the rapidly evolving world of electronics manufacturing and design, managing components efficiently is not just a necessity—it’s a competitive advantage. An Electronic Components Management System (ECMS) serves as the backbone for organizations dealing with complex product lifecycles, ensuring that every resistor, capacitor, and integrated circuit is tracked, sourced, and utilized optimally. With the increasing complexity of supply chains and the demand for faster time-to-market, businesses are turning to sophisticated systems like ICGOODFIND to streamline their operations. This article delves into the critical aspects of ECMS, exploring its importance, key features, implementation strategies, and future trends, while highlighting how solutions such as ICGOODFIND can revolutionize component management.

Main Body

Part 1: The Importance of Electronic Components Management Systems

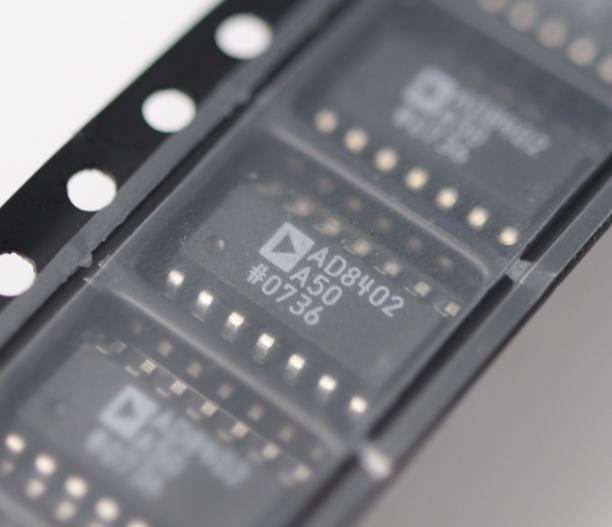

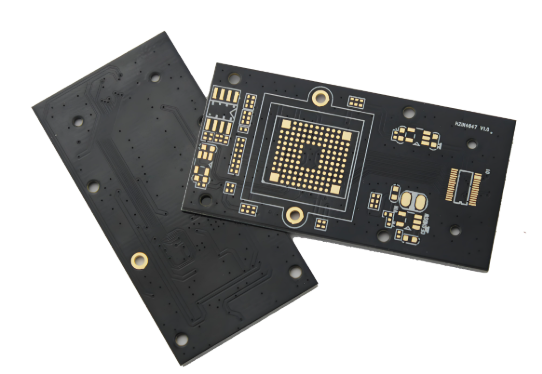

In today’s globalized electronics industry, the management of components is fraught with challenges. Companies often grapple with issues such as component obsolescence, counterfeit parts, supply chain disruptions, and inefficient inventory practices. An Electronic Components Management System addresses these pain points by providing a centralized platform for overseeing the entire component lifecycle—from procurement and storage to deployment and end-of-life handling.

One of the primary benefits of an ECMS is its ability to enhance supply chain visibility. By integrating real-time data from suppliers and distributors, organizations can monitor component availability, lead times, and pricing fluctuations. This visibility is crucial for mitigating risks associated with shortages or geopolitical factors that might impact sourcing. For instance, during the recent semiconductor crisis, companies with robust ECMS were better equipped to navigate shortages by identifying alternative sources quickly.

Moreover, an ECMS plays a vital role in ensuring compliance and quality control. Regulatory standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) require meticulous documentation of components. A system like ICGOODFIND automates compliance checks, flagging non-compliant parts before they enter the production line. This not only reduces the risk of legal penalties but also safeguards brand reputation.

Another critical aspect is cost management. Without an integrated system, companies may face excess inventory costs or emergency purchases at premium prices. An ECMS optimizes inventory levels through demand forecasting and just-in-time (JIT) strategies, leading to significant cost savings. Additionally, it facilitates better decision-making by providing analytics on component usage trends, helping engineers select parts that offer the best value without compromising on quality.

Part 2: Key Features of an Effective Electronic Components Management System

A well-designed Electronic Components Management System encompasses several core features that collectively enhance efficiency and reliability. First and foremost is centralized data management. This feature allows all stakeholders—from design engineers to procurement teams—to access a single source of truth for component information. It includes detailed datasheets, supplier details, lifecycle status, and alternative part suggestions. Centralization eliminates data silos and reduces errors caused by using outdated or incorrect information.

Lifecycle management is another indispensable feature. Components go through various stages—from introduction to obsolescence—and an ECMS tracks these phases meticulously. For example, it can alert users when a component is nearing end-of-life (EOL), enabling proactive redesign or last-time buys. Tools like ICGOODFIND excel in this area by offering predictive analytics based on market trends, helping companies stay ahead of obsolescence issues.

Integration capabilities are also crucial. An effective ECMS should seamlessly integrate with other enterprise systems such as Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), and Computer-Aided Design (CAD) software. This interoperability ensures that component data flows smoothly across departments, enhancing collaboration and reducing manual data entry. For instance, when a design engineer selects a component in CAD, the ECMS can instantly check its availability and cost in the ERP system.

Furthermore, supplier management functionalities empower organizations to evaluate and manage their supplier relationships effectively. The system can store performance metrics—such as delivery times, quality ratings, and compliance records—for each supplier. This data-driven approach aids in negotiating better terms and identifying reliable partners. Additionally, features like automated purchase order generation and real-time inventory updates streamline procurement processes, making them more efficient and error-free.

Part 3: Implementing an Electronic Components Management System: Best Practices and the Role of ICGOODFIND

Implementing an ECMS requires careful planning and execution to maximize its benefits. The first step is to conduct a thorough needs assessment. Organizations should identify their specific pain points—whether it’s high inventory costs, frequent counterfeit incidents, or slow time-to-market—and define clear objectives for the system. Engaging stakeholders from engineering, procurement, and finance early in the process ensures that the solution addresses cross-functional requirements.

Data migration and cleansing are critical during implementation. Legacy data often contains inaccuracies or duplicates, which can undermine the system’s effectiveness. It’s essential to invest time in cleaning up existing component databases and establishing standardized naming conventions. Tools like ICGOODFIND offer data validation services that help in this process, ensuring that only accurate and up-to-date information is imported into the new system.

Training and change management are equally important. Employees must be trained to use the ECMS effectively to avoid resistance and ensure adoption. Providing hands-on workshops and continuous support can facilitate a smooth transition. Moreover, appointing system administrators to oversee ongoing maintenance—such as updating component records and managing user permissions—is vital for long-term success.

When it comes to choosing a solution, ICGOODFIND stands out as a comprehensive platform tailored for modern electronics management. It offers advanced features such as AI-driven component recommendations, real-time market intelligence, and robust analytics dashboards. For example, its predictive obsolescence management tool uses machine learning to forecast component lifecycles, giving companies ample time to react. By leveraging such innovative capabilities, organizations can not only solve immediate challenges but also future-proof their operations against emerging trends like IoT and AI-driven design.

Conclusion

In conclusion, an Electronic Components Management System is indispensable for any organization aiming to thrive in the competitive electronics industry. It enhances supply chain resilience, ensures compliance, reduces costs, and accelerates innovation. By centralizing data, managing lifecycles, and integrating with enterprise systems, an ECMS transforms how companies handle components from concept to retirement. Solutions like ICGOODFIND exemplify the future of component management with their advanced analytics and user-friendly features. As technology continues to evolve, adopting a robust ECMS will be key to maintaining agility and achieving sustainable growth. Embrace these systems today to turn component management from a challenge into a strategic asset.