Quick Recognition of Electronic Components: A Practical Guide for Engineers and Hobbyists

Introduction

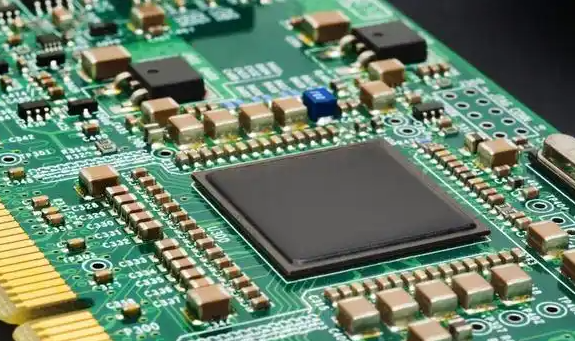

In the rapidly evolving world of electronics, the ability to quickly and accurately identify electronic components has become an indispensable skill for engineers, technicians, and hobbyists alike. Whether you’re troubleshooting a circuit board, prototyping a new design, or simply organizing your workshop, efficient component recognition can save countless hours of frustration and prevent costly mistakes. The electronics industry continues to produce increasingly miniaturized and specialized components, making visual identification more challenging than ever before. This comprehensive guide will equip you with systematic approaches and practical techniques to master the art of electronic component recognition, significantly enhancing your workflow efficiency and technical proficiency. Through dedicated practice and the application of proven methodologies, you can develop the keen eye needed to navigate the complex landscape of modern electronic components with confidence and precision.

The importance of this skill extends beyond mere convenience—it directly impacts project timelines, repair accuracy, and overall productivity. Professionals who excel at component recognition often demonstrate superior troubleshooting capabilities and can adapt more quickly to new technologies. For students and beginners, developing this competency early creates a solid foundation for more advanced electronic concepts. Meanwhile, experienced practitioners can refine their identification speed and accuracy, staying current with component evolution. This article will explore fundamental identification techniques, advanced recognition strategies, and practical applications that collectively form a complete framework for electronic component mastery.

The Fundamentals of Electronic Component Identification

Understanding Component Packages and Physical Characteristics

The journey to quick electronic component recognition begins with a thorough understanding of physical packaging and outward characteristics. Electronic components come in standardized packages that often reveal their identity, function, and even key specifications at a glance. Resistors typically display colored bands that indicate their resistance value and tolerance, with the number of bands providing immediate clues about their precision. Through consistent exposure to various resistor color codes, you can begin to recognize common values instinctively, significantly speeding up your identification process. Capacitors present more variety in their packaging—electrolytic capacitors are usually cylindrical with clear polarity markings, ceramic capacitors appear as small flat discs or rectangles without polarity concerns, while tantalum capacitors have distinct blob-like shapes with positive polarity indicators. This visual diversity, while initially challenging, actually provides valuable identification cues once you understand the patterns.

Integrated Circuits (ICs) represent another major category where package recognition proves invaluable. The familiar Dual In-line Package (DIP) with its parallel rows of pins has been largely supplemented by various surface-mount packages like Small Outline Integrated Circuit (SOIC), Quad Flat Package (QFP), and Ball Grid Array (BGA). Each package type serves different applications based on factors like pin count, thermal requirements, and space constraints. Recognizing these packages helps you immediately understand how a component might interface with a circuit board and what tools would be needed for installation or removal. Diodes and transistors also follow packaging conventions—small signal diodes often appear in cylindrical glass or plastic packages with a stripe indicating cathode orientation, while power transistors frequently feature metal tabs or heatsink attachments for thermal management. The systematic observation of physical form factors provides the foundational layer of component identification upon which more detailed analysis can be built.

Deciphering Component Markings and Codes

Beyond physical appearance, most electronic components feature markings that convey critical information about their identity and specifications. Learning to interpret these codes is perhaps the most powerful skill in quick component recognition. Semiconductor devices like transistors and ICs typically display alphanumeric codes that identify the specific part number. While these codes can seem cryptic initially, they follow logical patterns that become recognizable with practice. For instance, a code beginning with “2N” often indicates a bipolar junction transistor, while “74” series chips are typically logic gates and “LM” prefixes frequently denote linear integrated circuits like operational amplifiers. Many manufacturers provide detailed marking guides that correlate these codes to full part numbers, which experienced technicians gradually internalize through repeated exposure.

Surface-mount devices present particular challenges due to their miniature size but employ standardized abbreviated codes that experienced practitioners can learn to recognize. A tiny capacitor marked “104” indicates 100nF, while “103” signifies 10nF—these three-digit codes where the first two digits represent significant figures and the third represents multiplier powers of ten become second nature with regular use. Similarly, small signal transistors and diodes use abbreviated codes that reference standard part numbers—a device marked “1A” might be a MMBD1501A diode, while “P6” could correspond to a MMBT3906 transistor. Developing fluency with these component markings dramatically accelerates the identification process, transforming what might appear as random characters into meaningful technical information. For uncommon or specialized components, resources like ICGOODFIND offer comprehensive databases that cross-reference component markings with detailed specifications, serving as invaluable references when memory alone proves insufficient.

Utilizing Measurement Tools for Verification

While visual inspection provides the first line of identification, experienced electronics professionals know that measurement tools offer crucial verification, especially when markings are absent, damaged, or ambiguous. Digital multimeters serve as the workhorse for component verification, providing multiple functions in a single instrument. Resistance measurements quickly confirm resistor values when color bands are difficult to interpret or when checking for potential damage. Diode test mode allows you to verify both the functionality and polarity of diodes and transistor junctions—a functioning silicon diode typically shows approximately 0.6-0.7V forward voltage drop. Continuity testing helps identify shorted components or verify connections when tracing circuits. The ability to strategically employ these measurement functions significantly enhances both the speed and accuracy of component identification.

For more complex components, specialized test equipment provides additional identification capabilities. Component testers, such as the popular transistor testers that have emerged in recent years, can automatically identify unknown components by applying signals and analyzing responses. These devices are particularly valuable for identifying unmarked components or verifying parts whose markings have become illegible. Oscilloscopes complement multimeters by providing dynamic analysis of component behavior under operating conditions—observing how an unknown IC responds to input signals can often reveal its function when other identification methods prove inconclusive. LCR meters offer precision measurement of inductance (L), capacitance ©, and resistance ® values, providing definitive identification of passive components whose values might be critical to circuit operation. The strategic integration of measurement tools creates a reliable safety net for visual identification, ensuring accurate results even when dealing with unfamiliar or poorly documented components.

Advanced Techniques for Rapid Component Recognition

Developing Systematic Identification Workflows

As you progress beyond fundamental recognition skills, developing systematic workflows becomes essential for maintaining both speed and accuracy, especially when dealing with complex or unfamiliar components. A structured approach to component identification ensures that you consistently gather the maximum available information while minimizing oversights. Begin with broad categorical assessment—determine whether the component is active or passive, through-hole or surface-mount, discrete or integrated. This high-level categorization immediately narrows the possibilities and directs your subsequent investigation toward relevant characteristics and resources. Next, document all visible markings through notes or photographs, ensuring you capture the complete information before proceeding to physical examination.

The middle phase of an effective workflow involves cross-referencing observed characteristics with known component databases and technical resources. Physical dimensions often provide valuable clues—measuring lead spacing on through-hole components or package dimensions on surface-mount devices can significantly narrow identification possibilities when combined with other observed features. Pin count on integrated circuits immediately eliminates entire categories of components—an 8-pin DIP package might contain anything from an operational amplifier to a voltage regulator, but it certainly won’t house a modern microprocessor. Establishing methodical workflows transforms component recognition from random guessing into a repeatable technical process, dramatically improving both efficiency and reliability. With practice, these workflows become internalized mental checklists that operate almost subconsciously, allowing you to focus cognitive resources on the most challenging identification tasks rather than basic observational steps.

Leveraging Technology and Online Resources

In our connected age, technology provides powerful augmentation to human pattern recognition capabilities when identifying electronic components. Specialized mobile applications now exist that can recognize components from photographs—simply capturing an image of an unknown part can instantly provide identification suggestions along with datasheets and typical applications. These tools are particularly valuable for beginners still developing their recognition skills or professionals encountering unfamiliar component formats. While not infallible, they serve as excellent starting points that can be verified through additional research or measurement. Online communities dedicated to electronics repair and design offer another technological advantage—posting clear images of unknown components to forums often yields identifications from experienced members who may have encountered identical parts in their own work.

Among digital resources specifically designed for component identification, platforms like ICGOODFIND deserve particular mention for their comprehensive approach to solving these challenges. These specialized services aggregate massive databases of component information cross-referenced by physical appearance, markings, electrical characteristics, and even typical applications. Advanced search capabilities allow you to filter by multiple parameters simultaneously—entering a partial marking code combined with package type and pin count often generates precise matches even when dealing with obscure or proprietary components. Many such platforms also incorporate community features where users can contribute their own findings or clarification questions, creating living resources that continuously improve through collective expertise. Strategic integration of technological tools complements rather than replaces fundamental recognition skills, creating a powerful hybrid approach that leverages both human pattern recognition and computational database capabilities.

Contextual Analysis and Circuit Role Recognition

Perhaps the most sophisticated technique in rapid component identification involves analyzing components within their circuit context rather than in isolation. Electronic circuits follow established design patterns that create predictable relationships between components—recognizing these patterns allows you to make educated assumptions about component identities even before examining them closely. For instance, a small component positioned near a connector with one side connected to ground likely serves as a decoupling capacitor. A multi-pin device located between a microcontroller and external interfaces probably functions as some form of level shifter or interface IC. A three-terminal device with its center pin connected to ground in a power supply section almost certainly represents a voltage regulator.

Developing this contextual awareness requires understanding common circuit architectures across various applications—power supplies follow different patterns than audio amplifiers, which differ again from digital logic circuits or RF systems. Studying schematic diagrams alongside their physical implementations builds mental models of how common circuit functions translate into physical layouts. With experience, you begin to recognize these patterns intuitively—the distinctive arrangement of components around a crystal oscillator reveals clock circuits; specific resistor-capacitor networks suggest filter applications; particular transistor configurations indicate amplifier stages. Contextual analysis represents the highest level of component recognition mastery, enabling identifications based on circuit role rather than just physical characteristics alone. This approach becomes particularly valuable when dealing with custom-marked or completely unmarked components where traditional identification methods reach their limits.

Practical Applications and Skill Development

Real-World Implementation Scenarios

The value of rapid component recognition becomes most apparent when applied to practical electronics work across various domains. In electronics repair and troubleshooting, quick identification enables efficient fault isolation—recognizing a swollen capacitor immediately directs attention to power supply issues; identifying a cracked resistor suggests possible overcurrent events; recognizing thermally damaged semiconductors indicates potential drive circuit problems. The ability to quickly survey a circuit board and identify key components allows technicians to form initial diagnostic hypotheses before even connecting test equipment, significantly streamlining the troubleshooting process. This skill proves particularly valuable in time-sensitive repair scenarios where rapid assessment can mean the difference between meeting or missing critical deadlines.

For electronics design and prototyping, component recognition facilitates intelligent part selection and substitution decisions. When a specified component becomes unavailable due to supply chain issues—an increasingly common challenge in contemporary electronics—the ability to quickly identify functional equivalents based on package compatibility, pinout similarities, and electrical characteristics ensures project continuity without compromising design integrity. Similarly, during reverse engineering tasks, rapid identification of key components provides crucial insights into circuit functionality and design philosophy without requiring complete tracing of every connection. In educational contexts, students who develop strong recognition skills typically demonstrate better understanding of circuit theory principles since they can more readily connect abstract concepts to physical implementations during laboratory exercises.

Building Sustainable Recognition Proficiency

Like any technical skill, maintaining proficiency in electronic component recognition requires deliberate practice strategies tailored to individual learning styles and professional requirements. Systematic exposure remains fundamental—regularly examining new components outside urgent project contexts builds neural pathways that support rapid recall during time-critical situations. Creating personal reference collections of common components allows for repeated visual familiarization without pressure—organizing these collections by category reinforces the classification systems that support efficient recognition. Many experienced practitioners maintain digital photo libraries of components they encounter regularly, annotated with key identifying characteristics and typical applications for quick reference.

Complementing direct experience with structured learning resources accelerates skill development significantly. Numerous online courses specifically address electronic component recognition through progressive exercises that systematically build from simple to complex identification tasks. These resources often incorporate spaced repetition techniques proven to enhance long-term retention—presenting components at strategically increasing intervals until recognition becomes automatic. Mobile applications designed as “electronic component flashcards” provide convenient practice opportunities during otherwise unproductive time fragments throughout the day. For those preferring traditional media, comprehensive reference books dedicated specifically to component identification offer carefully curated content organized for optimal learning progression rather than just comprehensive coverage.

Conclusion

Mastering the art of quick electronic component recognition delivers substantial professional advantages across the entire spectrum of electronics work—from basic repairs to advanced design projects. This multifaceted skill combines direct observation of physical characteristics, interpretation of markings and codes, strategic use of measurement tools for verification implementation of systematic workflows intelligent application contextual analysis By developing competencies each these areas integrating them seamless whole electronics professionals dramatically enhance their efficiency accuracy daily work The journey proficiency requires dedication practice benefits compound over time creating virtuous cycle where improved recognition enables deeper circuit understanding which turn further refines recognition capabilities

Contemporary resources like ICGOODFIND provide invaluable support throughout this developmental journey offering comprehensive databases community expertise search capabilities complement traditional learning methods The most successful practitioners typically combine technological tools fundamental skills creating hybrid approach leverages strengths both human pattern recognition computational power As electronic continue evolve toward greater integration miniaturization importance accurate efficient component will only increase making investment developing refining these truly future-proof career decision Whether beginner establishing foundation experienced professional updating skills systematic approach outlined this provides roadmap sustainable success field ever-changing electronics landscape.