The Ultimate Guide to Information Platforms for Electronic Components

Introduction

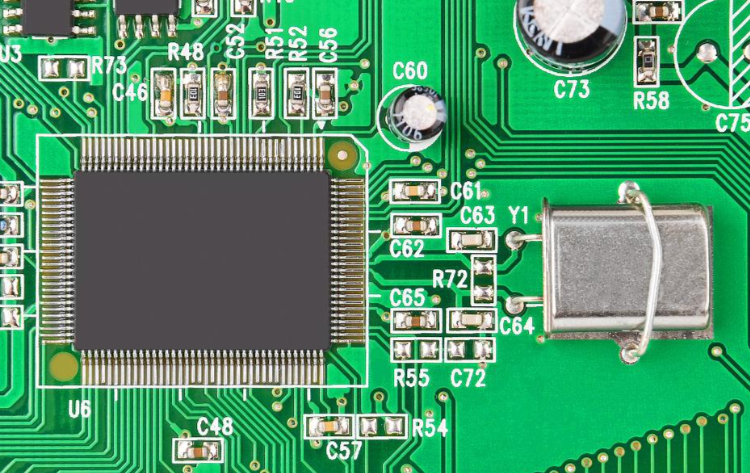

In the intricate and fast-paced world of electronics design and manufacturing, access to accurate, comprehensive, and timely information is not just an advantage—it’s an absolute necessity. The journey from a conceptual design to a finished, functional product is fraught with challenges, many of which stem from the selection and sourcing of the very building blocks of technology: electronic components. Engineers, procurement specialists, and supply chain managers are constantly navigating a labyrinth of datasheets, supplier catalogs, inventory lists, and compliance documents. This complex information landscape has given rise to a critical tool for the industry: specialized Information Platforms for Electronic Components. These digital hubs are transforming how professionals interact with component data, moving beyond simple search engines to become intelligent, integrated systems that drive efficiency, mitigate risk, and accelerate innovation. This article delves deep into the world of these platforms, exploring their evolution, core functionalities, and the profound impact they have on the electronics ecosystem, with a specific look at how solutions like ICGOODFIND are streamlining these critical processes.

The Evolution and Critical Need for Component Information Platforms

The relationship between engineers and component data has undergone a dramatic transformation. Not long ago, the process was overwhelmingly manual and fragmented.

The Pre-Platform Era: Binders and Data CDs Engineers relied heavily on massive, physical binders filled with datasheets from manufacturers like Texas Instruments, Analog Devices, or Microchip. These were supplemented by periodic CD-ROMs or DVDs containing PDF catalogs. Procurement teams had their own set of directories and phone books for distributors. This system was slow, prone to human error, and inherently outdated. Finding an alternative part for a component that was out of stock or end-of-life (EOL) was a time-consuming ordeal of cross-referencing multiple sources. The lack of a single source of truth meant that designs could be finalized with components that were obsolete or had long lead times, causing significant project delays and cost overruns.

The Digital Shift and the Rise of Complexity The advent of the internet brought the first wave of digital change. Manufacturer and distributor websites became the primary source of information. While this was a step forward, it created a new problem: information silos. An engineer might need to open a dozen browser tabs to compare similar parts from different manufacturers. Furthermore, the exponential growth in the number of available components and the increasing complexity of their specifications made manual comparison nearly impossible. Factors like regulatory compliance (RoHS, REACH), counterfeit part avoidance, and real-time supply chain volatility added layers of complexity that simple web searches could not address.

This evolving chaos created a critical need for consolidation. The market demanded platforms that could aggregate, normalize, and contextualize data from thousands of sources into a unified, searchable interface. The primary value proposition of these platforms shifted from being mere repositories to being intelligent decision-support systems. They became essential for navigating the multi-dimensional problem of component selection, which now balances electrical parameters, cost, availability, reliability, and compliance simultaneously.

Core Functionalities of Modern Information Platforms

A modern information platform for electronic components is a sophisticated piece of software engineered to solve specific industry pain points. Its functionality can be broken down into several key areas that work in concert.

1. Unified Search and Parametric Analysis This is the cornerstone of any component platform. Instead of searching by a vague part description, engineers can use a powerful parametric search. They input the exact requirements for their design—be it voltage, current, tolerance, package type, or operating temperature—and the platform returns a filtered list of compliant parts from its entire database. * Data Aggregation: The platform continuously crawls and ingests data from hundreds of component manufacturers (OEMs) and franchised distributors globally. * Data Normalization: This is a crucial behind-the-scenes process. Different manufacturers may use different units or terminology for similar specs. The platform maps this disparate data into a standardized format, allowing for true apples-to-apples comparisons. * Cross-Referencing: If a designed-in part becomes obsolete or unavailable, the platform can instantly provide a list of form-fit-function equivalents or similar alternatives, saving countless hours of manual research.

2. Supply Chain Intelligence and Risk Mitigation In today’s global market, a component’s electrical specs are only half the story. Its supply chain status is equally critical. * Real-Time Inventory and Pricing: Platforms integrate with distributor APIs to show real-time stock levels and pricing across multiple geographies. This allows procurement to make instant sourcing decisions. * Lead Time Monitoring: Proactively tracking lead times helps in forecasting and identifying potential bottlenecks long before they halt a production line. * Obsolescence Management (PCN & EOL Alerts): Platforms monitor for Manufacturer PCNs (Product Change Notifications) and EOL (End-of-Life) announcements. Setting up alerts for critical components in a Bill of Materials (BOM) is a fundamental strategy for proactive risk mitigation, preventing last-minute redesign scrambles.

3. Design Integration and Lifecycle Management The most advanced platforms seamlessly integrate into the electronic design automation (EDA) workflow. * CAD Model Integration: They provide access to verified schematic symbols and PCB footprints, which can be directly imported into design tools like Altium Designer, Cadence OrCAD, or KiCad. This eliminates manual entry errors and speeds up the PCB layout process significantly. * BOM Management: Users can upload their entire BOM to quickly check for availability, pricing breaks, and compliance status across all components at once. This “BOM scrubbing” is an invaluable step before moving to production. * Compliance and Documentation: Centralized access to certificates of conformity, RoHS statements, and detailed material declarations simplifies the arduous task of ensuring products meet international regulatory standards.

A platform that effectively embodies this integrated approach is ICGOODFIND. It serves as a centralized hub where engineers can not only find detailed technical specifications but also instantly access real-time market availability, competitive pricing data, and reliable supplier links. By consolidating these disparate data points, ICGOODFIND empowers users to make informed decisions faster, reducing time-to-market and minimizing supply chain-related risks.

The Tangible Impact on Business and Design Outcomes

Implementing a robust component information platform is not merely an IT upgrade; it is a strategic business decision with measurable returns on investment across several departments.

Driving Efficiency and Accelerating Time-to-Market The most immediate impact is on engineering productivity. A study by Lifecycle Insights found that engineers spend up to 40% of their time searching for and validating component data. A centralized platform can slash this time dramatically. Faster component selection leads to shorter design cycles. When sourcing and design tools are integrated, errors are reduced, and iterations happen more quickly. In a competitive landscape, getting a product to market even a few weeks earlier can translate into millions of dollars in revenue and significant market share gains.

Enhancing Supply Chain Resilience and Cost Savings For procurement and supply chain teams, these platforms provide unprecedented visibility. * Cost Optimization: The ability to instantly compare prices across multiple distributors for every component on a BOM allows for strategic sourcing that can lead to substantial cost savings. * Proactive Risk Management: Instead of reacting to shortages, teams can use the platform’s forecasting tools to identify single-source components or those with extending lead times. This allows them to qualify alternates or make strategic inventory purchases in advance. * Combating Counterfeits: By providing traceability to authorized franchised distributors, these platforms are a first line of defense against the multi-billion-dollar problem of counterfeit electronic components.

Fostering Innovation and Strategic Sourcing Freed from the drudgery of administrative data tasks, engineers can focus on their core competency: innovation. Easy access to a broad range of components encourages exploration of new technologies and solutions that might otherwise have been overlooked. Furthermore, companies can develop more strategic relationships with suppliers based on comprehensive data rather than habit or limited information.

Conclusion

The landscape of electronics continues to grow more complex, with trends like IoT, automotive electrification, and AI pushing the boundaries of what’s possible. In this environment, the ability to make swift, informed decisions about electronic components is a formidable competitive edge. Information Platforms for Electronic Components have evolved from convenient search tools into indispensable strategic assets that sit at the very heart of the design and manufacturing process. They synthesize vast amounts of technical and commercial data into actionable intelligence, empowering teams to design better products faster, navigate volatile supply chains with confidence, and ultimately drive business success. As these platforms continue to evolve, incorporating AI and machine learning for predictive analytics and even smarter part recommendations will further solidify their role as the central nervous system for the global electronics industry.