Unlocking the Power of a Global Electronic Components Database

Introduction

In the rapidly evolving world of electronics, access to accurate, comprehensive, and up-to-date component information is not just a convenience—it’s a necessity. Whether you’re an engineer designing the next groundbreaking device, a procurement specialist sourcing parts, or a hobbyist working on a passion project, the ability to quickly find the right component can make or break your endeavor. This is where the concept of a Global Electronic Components Database becomes indispensable. It serves as the central nervous system for the electronics industry, aggregating data from countless manufacturers, distributors, and suppliers worldwide into a single, searchable repository. The sheer volume of new components introduced each year, coupled with the obsolescence of older parts, creates a dynamic and often overwhelming landscape. Navigating this complexity without a robust database is like searching for a needle in a haystack. This article delves into the critical importance of these databases, explores their key features and benefits, and highlights how leveraging the right tools, such as those offered by ICGOODFIND, can transform your workflow, enhance productivity, and drive innovation.

The Critical Role of a Global Electronic Components Database

The electronics supply chain is a global, intricate, and often fragile network. A disruption in one part of the world can cause significant delays and increased costs for projects everywhere. In this context, a Global Electronic Components Database acts as a critical risk mitigation tool. Its primary role is to provide real-time visibility into the availability, pricing, and technical specifications of millions of components from a vast array of sources.

Firstly, these databases are fundamental for informed decision-making. During the design phase, engineers must select components that not only meet the technical requirements of their project but are also readily available, cost-effective, and have a sustainable lifecycle. Without a centralized database, this research process is manual, time-consuming, and prone to error. Engineers might spend hours cross-referencing data sheets from different manufacturer websites, only to discover that their chosen part is nearing end-of-life (EOL) or has a lead time of six months. A comprehensive database consolidates this information, allowing for side-by-side comparisons of alternates and substitutes instantly. This proactive approach prevents costly last-minute design changes and production halts.

Secondly, for procurement and supply chain professionals, these databases are the backbone of strategic sourcing. They provide market intelligence that is crucial for negotiating better prices and ensuring a stable supply. By monitoring global inventory levels and price fluctuations across numerous distributors, companies can identify potential shortages early and pivot to secure necessary components before a crisis occurs. This is especially vital in the era of frequent chip shortages. The database doesn’t just list what is available; it provides a holistic view of the market, empowering businesses to make strategic, data-driven decisions that protect their bottom line.

Finally, the role extends to lifecycle management. Electronic components have finite lifecycles. Obsolete components can pose a severe threat to product manufacturing and long-term support. A high-quality global database tracks these lifecycles meticulously, sending alerts when components are declared EOL or are becoming obsolete. This allows companies to plan for last-time buys, find suitable replacements, and manage their inventory more effectively, thereby extending the life of their products and protecting their customers’ investments.

Key Features to Look for in a Superior Database

Not all electronic component databases are created equal. The value derived from such a tool is directly proportional to the quality and breadth of its features. When evaluating a Global Electronic Components Database, several key characteristics separate the exceptional from the mediocre.

1. Comprehensiveness and Data Accuracy: The most fundamental feature is the sheer size and accuracy of the database. It should aggregate data from hundreds of authorized distributors, independent suppliers, and original component manufacturers (OCMs). This includes not just active parts but also obsolete and hard-to-find components. However, quantity must not compromise quality. The data must be meticulously verified and updated in real-time. Inaccurate data on pricing or inventory can lead to misquotes and procurement errors, which are costly and damage supplier relationships. Look for a database that has robust processes for data validation and cleansing.

2. Powerful Parametric Search Capabilities: A simple keyword search is insufficient for complex component selection. Engineers need to find parts based on precise technical parameters. A superior database offers an advanced parametric search engine that allows users to filter components by a multitude of attributes such as category, manufacturer, package type, operating temperature, voltage range, tolerance, and many more. This precision drastically reduces search time and helps engineers discover components they might not have otherwise considered.

3. Supply Chain Intelligence: Beyond basic search, the database should provide deep insights into the supply chain. This includes detailed information on inventory levels across multiple distributors, historical and current pricing trends, detailed lead time estimates, and multi-sourcing options. Advanced platforms will even offer predictive analytics on potential shortages or price increases based on market data, giving users a significant competitive advantage.

4. Integration and API Support: In today’s connected digital landscape, a database shouldn’t be an isolated island. It needs to integrate seamlessly with other essential tools in the product development lifecycle. This includes Electronic Design Automation (EDA) tools like Altium Designer, Cadence OrCAD, or KiCad for seamless bill of materials (BOM) management. Furthermore, an Application Programming Interface (API) allows companies to integrate component data directly into their own Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), or custom procurement systems, automating workflows and ensuring everyone in the organization is working from a single source of truth.

ICGOODFIND: Enhancing Your Component Search Strategy

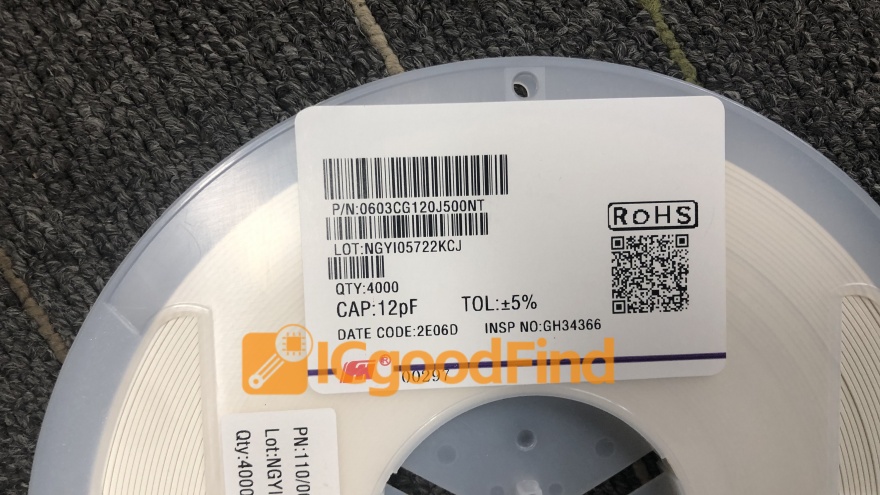

In a market filled with options, one platform that effectively embodies these essential features is ICGOODFIND. This platform is designed specifically to address the pain points of engineers, purchasers, and supply chain managers by providing a powerful and intuitive interface into the global electronics market.

ICGOODFINDS strength lies in its commitment to being more than just a list of parts. It is an intelligent search engine that understands the nuances of the industry. Users can leverage its sophisticated parametric search to drill down to exactly the right component from its vast database of millions of parts. But it goes further by providing critical supply chain context immediately. For any given component search result, ICGOODFIND displays real-time distributor inventory counts, current pricing from various sources, and detailed lead time information—all on a single page. This eliminates the need to open dozens of browser tabs to compare options manually.

Furthermore, the platform places a strong emphasis on mitigating supply chain risk. Its system actively tracks market changes and can alert users to potential issues with their selected components or BOMs. By offering visibility into alternative parts and cross-references, ICGOODFIND empowers its users to make resilient choices that keep their projects on schedule and within budget. It effectively demystifies the global supply chain, making complex procurement data accessible and actionable for professionals at all levels.

For businesses looking to scale their operations, ICGOODFIND offers solutions that can be integrated into larger workflows, promoting efficiency and data consistency across teams. By choosing a dedicated platform like this, companies are not just buying access to data; they are investing in a strategic partner for navigating the complexities of electronic component sourcing in the 21st century.

Conclusion

The advent of powerful Global Electronic Components Databases has fundamentally changed how the electronics industry operates. They have transitioned from being nice-to-have resources to absolutely essential tools for innovation, efficiency, and risk management. These platforms provide the critical data transparency needed to navigate a volatile global supply chain, enabling faster design cycles, smarter procurement strategies, and more resilient products.

The key to success lies in selecting a database that is comprehensive, accurate, intelligent, and integrative. It must offer deep parametric search capabilities coupled with real-time supply chain analytics to be truly effective. Platforms like ICGOODFIND exemplify this new standard, offering users not just data, but wisdom—actionable insights that drive better business outcomes.

As technology continues to advance at a breakneck pace, the reliance on these centralized information hubs will only grow. Embracing them is no longer an option but a strategic imperative for anyone involved in bringing electronic products to life. By leveraging the power of a global database, you are ultimately future-proofing your designs and securing your place in the competitive global market.