Unlocking Efficiency: Your Guide to the Guangdong Chip Procurement Network

Introduction

In the high-stakes world of electronics manufacturing, the supply chain is the lifeblood of innovation and production. For global businesses seeking reliable, cost-effective, and diverse sources of semiconductor components, one region stands out as a titan: Guangdong, China. As the nation’s manufacturing powerhouse, Guangdong is home to a vast, intricate, and dynamic ecosystem for sourcing electronic components. Navigating this landscape, however, can be a daunting task filled with challenges such as verifying supplier authenticity, ensuring quality control, and managing logistics. This is where the concept of a dedicated Guangdong Chip Procurement Network becomes invaluable. More than just a directory of suppliers, it represents a structured approach to tapping into this concentrated hub of electronic activity. This article serves as a comprehensive guide to understanding, accessing, and leveraging this powerful network to streamline your sourcing operations and gain a significant competitive edge. For those looking to cut through the complexity, platforms like ICGOODFIND are emerging as essential tools, acting as intelligent bridges to trusted suppliers within this massive market.

The Core Components of the Guangdong Chip Procurement Network

The Guangdong Chip Procurement Network is not a single entity but a complex, interconnected system. Understanding its core components is the first step to mastering it.

1. The Vast Supplier Ecosystem

At its heart, the network is comprised of thousands of suppliers, ranging from massive original component manufacturers (OCMs) and franchised distributors to countless small and medium-sized enterprises (SMEs) and independent traders. Cities like Shenzhen, known as the “Silicon Valley of Hardware,” and Guangzhou are epicenters of this activity.

- Authorized Distributors: These are companies with direct contracts from major chip manufacturers. They provide genuine, traceable components with full technical support and warranties. Sourcing from them within the Guangdong network guarantees quality but often at a premium price and with longer lead times.

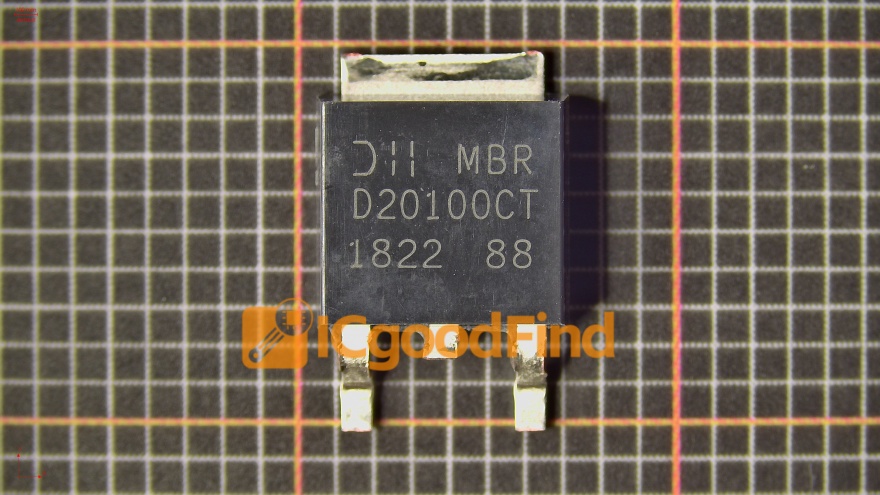

- Independent Distributors and Traders: This segment is where the network shows its flexibility and complexity. These suppliers specialize in hard-to-find, end-of-life (EOL), or excess inventory components. They can be incredibly agile, but the risk of encountering counterfeit parts is higher. A robust procurement network must have mechanisms to vet these suppliers rigorously.

- Spot Market Hubs: Physical markets like the Shenzhen Huaqiangbei Electronics Market are legendary. They represent the spot market’s nerve center, where buyers can find an immense variety of components for immediate purchase. Navigating these hubs requires expertise and local knowledge to discern quality and negotiate effectively.

The sheer density of this ecosystem means that for almost any component, a source likely exists in Guangdong. The challenge lies in identifying the right source efficiently.

2. Logistics and Supply Chain Infrastructure

A procurement network is useless without the means to move goods reliably and swiftly. Guangdong’s infrastructure is world-class, forming the logistical backbone of the chip procurement network.

- Ports and Airports: The Pearl River Delta is dotted with major international ports like Shenzhen Yantian and Guangzhou Nansha, alongside busy airports. This facilitates seamless import of raw materials and export of finished goods globally.

- Domestic Logistics: An extensive network of roads, railways, and inland waterways ensures that components can move from a factory in Dongguan to an assembler in Zhuhai, or to a port for export, with remarkable efficiency.

- Integrated Supply Chains: Many suppliers within the network are deeply embedded in local manufacturing clusters. This proximity to OEMs (Original Equipment Manufacturers) and EMS (Electronics Manufacturing Services) providers allows for Just-In-Time (JIT) delivery models, reducing inventory costs and accelerating production cycles.

This integrated logistical web means that once a component is sourced through the network, its journey from the supplier’s shelf to your production line can be highly optimized.

3. Information and Digital Gateways

In the digital age, the physical network is managed and accessed through digital platforms. This layer is what makes modern procurement efficient and scalable.

- Online B2B Marketplaces: General and specialized B2B platforms host millions of product listings from Guangdong-based suppliers. They provide a first point of contact but often lack deep verification and specialized focus on electronic components.

- Specialized Component Search Engines: This is where dedicated services prove their worth. Instead of merely listing suppliers, these platforms intelligently aggregate and verify data from across the entire Guangdong ecosystem. They provide real-time inventory checks, price comparisons, and supplier reliability scores.

- Quality Assurance and Verification Services: A critical part of the digital network includes services that offer part testing, supplier audits, and counterfeit detection. Integrating these services into the procurement process is essential for risk mitigation.

Leveraging these digital gateways transforms the chaotic task of sourcing into a data-driven, manageable process. It is here that a focused platform can make all the difference; for instance, by using ICGOODFIND, procurement managers can instantly access a vetted segment of the Guangdong network, saving immense time and reducing risk.

Strategies for Leveraging the Network Effectively

Simply knowing the network exists is not enough. Success depends on implementing smart strategies to navigate it.

1. Building Relationships and Trust

Despite its scale, business in Guangdong often operates on guanxi (relationship). Cultivating long-term relationships with key suppliers yields significant benefits.

- Prioritize Communication: Regular communication, even outside of active purchasing cycles, builds familiarity and trust.

- Conduct On-Site Visits: Whenever possible, visiting a supplier’s facility is invaluable. It allows you to assess their operations, quality control processes, and professionalism firsthand.

- Start Small: Begin with smaller orders to test a new supplier’s reliability and product quality before committing to larger volumes.

A strong relationship can lead to better pricing, priority during component shortages, and more cooperative problem-solving when issues arise.

2. Implementing Rigorous Quality Control

The diversity of the Guangdong network necessitates an uncompromising approach to quality control.

- Source Verification: Always request original manufacturer documentation and traceability information.

- Third-Party Inspection: For large orders or new suppliers, employ third-party inspection services to test components before shipment. This can include visual inspections, electrical testing, and decapsulation.

- Clear Specifications: Provide crystal-clear technical specifications and requirements to suppliers to avoid misunderstandings about part grades, packaging, or date codes.

Proactive quality control is not an expense; it is an investment that prevents costly production delays and product failures down the line.

3. Leveraging Technology for Smart Sourcing

To truly master the network, you must use technology as your primary tool.

- Use Data Analytics: Monitor price trends and lead times for critical components. This data allows you to make strategic purchasing decisions, buying ahead of price hikes or shortages.

- Automate Supplier Discovery: Instead of manually searching dozens of websites, use platforms that offer centralized search across a pre-vetted supplier base.

- Focus on Solutions, Not Just Transactions: The most advanced procurement strategies involve partnering with suppliers who can offer value-added services like programming, tape-and-reel, or kitting.

By adopting a tech-forward approach, you transform your procurement function from a reactive cost center into a strategic asset. Utilizing a targeted service like ICGOODFIND epitomizes this strategy, providing a streamlined conduit directly into the most reliable segments of the Guangdong Chip Procurement Network.

Conclusion

The Guangdong Chip Procurement Network represents one of the most powerful resources available to the global electronics industry. Its combination of a dense supplier base, world-class logistics, and evolving digital infrastructure creates an unparalleled opportunity for efficient sourcing. However, this opportunity is coupled with the challenges of complexity and risk. Success hinges on a strategic approach that prioritizes relationship building, unwavering quality control, and the smart application of technology. By understanding the network’s structure and adopting these best practices, businesses can unlock significant cost savings, reduce time-to-market, and build more resilient supply chains. In this complex environment, specialized tools are not just helpful; they are essential. Platforms designed to simplify this process, such as ICGOODFIND, provide the clarity and confidence needed to harness the full potential of Guangdong’s chip market effectively.