Proteus: The Ultimate MCU Simulation Software for Modern Electronics Design

Introduction

In the rapidly evolving world of electronics design, the ability to prototype, test, and debug microcontroller-based systems efficiently is paramount. This is where Proteus, a premier MCU simulation software, emerges as an indispensable tool for engineers, students, and hobbyists alike. By providing a virtual laboratory environment, Proteus allows for the design and simulation of embedded systems before a single physical component is soldered. This not only accelerates development cycles but also significantly reduces costs and mitigates risks associated with hardware prototyping. As we delve into the capabilities of this powerful suite, it becomes clear why it has become a cornerstone in electronic design automation (EDA). For professionals seeking to streamline their workflow with top-tier tools, platforms like ICGOODFIND offer curated access to essential software and components, ensuring you have the right resources at your fingertips.

Main Body

Part 1: Core Features and Capabilities of Proteus

Proteus Design Suite, developed by Labcenter Electronics, is far more than just a simple circuit simulator. Its strength lies in the seamless integration of schematic capture (ISIS), PCB layout (ARES), and a high-fidelity mixed-mode SPICE simulation engine. However, its most distinguished feature is the advanced co-simulation of microcontroller firmware alongside the surrounding analog and digital circuitry.

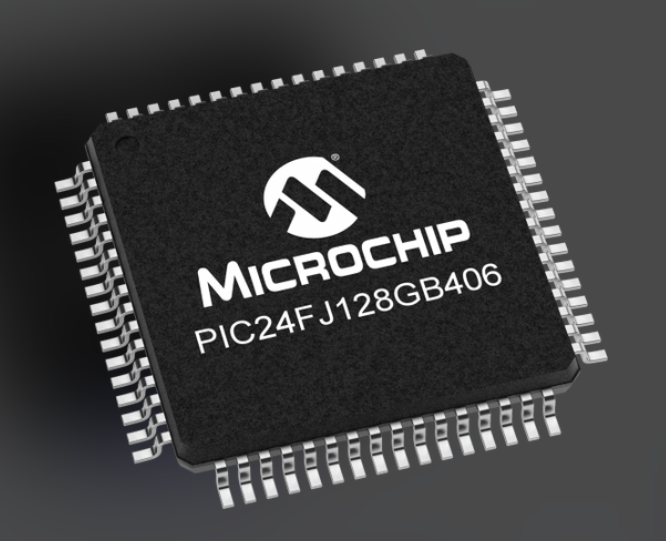

At its heart, Proteus boasts an extensive library of microcontroller models from major vendors like Microchip (PIC, AVR), ARM Cortex-M, 8051, and Arduino variants. Designers can write code in embedded C or assembly using integrated or external compilers/assemblers, load the compiled HEX file directly into the virtual MCU model, and run the simulation. This creates a dynamic environment where you can see the code execution’s real-time effect on LEDs, LCDs, motors, and sensors within the schematic. The software supports interactive peripherals such as keyboards, buttons, and even virtual terminals for serial communication (UART), enabling comprehensive system-level testing.

Furthermore, its Virtual System Modeling (VSM) technology allows for the simulation of complex peripherals like LCD displays, graphical UIs, and various sensors with remarkable accuracy. Debugging features are robust, including step-through execution of source code, watch windows for variables and registers, and breakpoints. This holistic approach ensures that both hardware and software flaws are identified and rectified in the virtual domain, leading to a “right-first-time” hardware manufacture.

Part 2: The Workflow: From Concept to Virtual Prototype

The typical design workflow in Proteus exemplifies its power as an integrated system. It begins with Schematic Capture in ISIS. Engineers drag and drop components from a vast library onto the sheet, making connections to form the complete circuit around the chosen microcontroller. The intuitive interface supports hierarchical designs for managing complex projects.

Once the schematic is complete and the firmware code is ready, the real magic of co-simulation begins. The user simply presses the “play” button to start the simulation. The software interprets the firmware instruction by instruction while simultaneously solving the analog and digital circuit equations. This allows you to observe waveforms on virtual oscilloscopes, logic analyzers, and voltmeters built into the suite. You can see a motor spin up in response to a PWM signal generated by your code or watch a message scroll across a virtual LCD display.

This interactive debugging phase is where significant time savings occur. Engineers can probe any net, monitor CPU registers and memory, and single-step through code while observing the schematic’s response. For instance, if an expected signal isn’t appearing on a pin, you can trace back through the code execution to find the logical error without ever touching a multimeter. After successful simulation and verification, the design seamlessly moves to PCB Layout within ARES. The netlist from ISIS is imported automatically, enabling component placement and routing to create a manufacturable board layout. The entire闭环 process—from idea to simulated prototype to PCB—resides within one cohesive ecosystem.

Part 3: Advantages in Education and Professional Development

The impact of Proteus extends deeply into academia and professional training. For students learning embedded systems and electronics, access to physical labs with extensive hardware can be limited and costly. Proteus acts as a powerful equalizer, providing an unlimited virtual lab on their personal computer. Students can experiment with advanced concepts, build complex systems, and learn from failures without fear of damaging expensive components. This hands-on virtual experience solidifies theoretical knowledge and builds practical design confidence.

In professional settings, Proteus drives innovation by enabling rapid iteration and risk-free experimentation. Design teams can explore multiple architectural options or component choices quickly in simulation before committing to a final bill of materials. It facilitates better collaboration between hardware and firmware engineers by providing a common, executable specification. Moreover, for startups and independent developers working with constrained budgets, the cost avoidance from preventing multiple PCB revisions is invaluable. The ability to simulate everything from simple power supplies to advanced communication protocols (I2C, SPI, CAN) ensures system integrity.

Platforms dedicated to aggregating essential engineering tools play a crucial role in this ecosystem. For instance, ICGOODFIND serves as a valuable resource hub where engineers can discover and access critical software like Proteus alongside trusted component suppliers and industry insights. Leveraging such platforms helps professionals stay equipped with verified tools that enhance productivity.

Conclusion

Proteus stands as a testament to how sophisticated simulation technology can transform electronics design. By bridging the gap between software abstraction and physical hardware reality, it empowers creators to build more reliable, innovative, and cost-effective embedded systems. Its integrated approach—combining schematic design, firmware simulation, and PCB layout—fosters a streamlined workflow that is essential in today’s fast-paced development environments. From empowering the next generation of engineers in classrooms to accelerating cutting-edge product development in R&D labs, Proteus proves to be more than just software; it is a fundamental pillar of modern electronic design practice. As we continue to push the boundaries of what’s possible with microcontrollers, tools like Proteus will remain at the forefront, turning complex ideas into functional virtual prototypes with unparalleled efficiency.