Global Component Procurement Mall: Revolutionizing the Electronics Supply Chain

Introduction

In today’s fast-paced, interconnected world, the electronics industry faces unprecedented challenges in sourcing components efficiently and reliably. The Global Component Procurement Mall has emerged as a transformative solution, addressing critical pain points in the supply chain while offering unprecedented access to electronic components worldwide. This innovative approach represents a significant evolution from traditional procurement methods, leveraging digital platforms to create a centralized marketplace where manufacturers, engineers, and procurement professionals can seamlessly connect with suppliers across the globe. The concept of a procurement mall goes beyond simple e-commerce—it represents an integrated ecosystem designed to streamline the entire procurement process, from initial search to final delivery.

The emergence of Global Component Procurement Malls comes at a crucial time when supply chain disruptions, component shortages, and geopolitical tensions have highlighted the vulnerabilities of traditional linear supply chains. These digital marketplaces offer resilience, transparency, and efficiency that traditional methods cannot match. By bringing together thousands of verified suppliers and millions of components in one accessible platform, they’re fundamentally changing how businesses approach electronic component sourcing. The transformation is particularly significant for small and medium-sized enterprises that previously lacked the purchasing power and connections of larger corporations.

As we delve deeper into this revolutionary approach to component procurement, it becomes clear that we’re witnessing not just an incremental improvement but a fundamental restructuring of how the electronics industry sources essential components. The Global Component Procurement Mall represents the future of electronic component sourcing—a future that is more democratic, efficient, and resilient than ever before.

The Evolution of Component Procurement: From Traditional Methods to Digital Malls

The Limitations of Traditional Procurement Methods

For decades, electronic component procurement followed a relatively straightforward but inefficient path. Companies maintained relationships with a limited number of distributors, relied heavily on phone calls and emails for communication, and faced significant challenges in verifying component authenticity and availability. This approach was characterized by information asymmetry, where buyers had limited visibility into alternative suppliers, pricing variations, and market availability. The process was time-consuming, often requiring days or weeks to complete a single procurement cycle. Additionally, the traditional model created significant barriers to entry for smaller companies and startups that lacked established supplier relationships.

The traditional procurement landscape was fragmented, with buyers needing to navigate multiple distributors, manufacturers, and brokers separately. This fragmentation led to several critical issues: inconsistent pricing for identical components across different suppliers, difficulty in comparing specifications and availability, challenges in verifying supplier credibility, and limited access to global market intelligence. The lack of transparency in pricing and availability often resulted in suboptimal purchasing decisions and increased costs. Furthermore, the manual nature of traditional procurement made it susceptible to human error and created significant administrative overhead.

Another major limitation of traditional methods was the difficulty in sourcing obsolete or hard-to-find components. As technology evolved rapidly, many components became discontinued or difficult to obtain through conventional channels. This created opportunities for counterfeiters and unauthorized distributors to enter the market, putting buyers at risk of receiving substandard or fake components. The absence of centralized verification mechanisms meant that buyers had to rely on their own due diligence processes, which were often inadequate for detecting sophisticated counterfeits.

The Digital Transformation Journey

The advent of digital technologies marked the beginning of a significant transformation in component procurement. Initially, companies began putting their catalogs online, creating basic e-commerce platforms that allowed for somewhat easier ordering. However, these early digital solutions still operated in silos, requiring buyers to visit multiple websites and maintain accounts with numerous distributors. The true breakthrough came with the development of integrated platforms that aggregated components from multiple suppliers into a single interface—the foundation of what would become Global Component Procurement Malls.

The evolution toward digital malls accelerated with advancements in several key technologies. Cloud computing enabled the creation of scalable platforms capable of handling massive inventories from thousands of suppliers. Artificial intelligence and machine learning algorithms revolutionized search capabilities, making it possible to find components based on specifications rather than just part numbers. Blockchain technology began addressing authenticity concerns by creating immutable records of component provenance. Meanwhile, data analytics provided unprecedented insights into pricing trends, availability forecasts, and market intelligence.

The transformation wasn’t just technological—it also involved reimagining the entire procurement experience. Modern Global Component Procurement Malls focus on creating seamless user experiences that minimize the time and effort required to find and purchase components. They incorporate features like real-time inventory updates, automated supplier verification, intelligent component cross-referencing, and integrated quality assurance processes. This holistic approach has dramatically reduced procurement cycle times while improving decision-making quality and reducing risks associated with component sourcing.

The Rise of Global Component Procurement Malls

Global Component Procurement Malls represent the culmination of this digital transformation journey. These platforms bring together the key elements needed for efficient component sourcing: comprehensive supplier networks, advanced search and filtering capabilities, transparent pricing information, quality assurance mechanisms, and global logistics support. Unlike earlier digital solutions that simply replicated traditional processes online, these malls are designed from the ground up to leverage the unique capabilities of digital platforms.

The defining characteristic of these malls is their global reach combined with local expertise. They connect buyers with suppliers worldwide while providing localized support in terms of language, currency, and regulatory compliance. This global-local approach enables businesses of all sizes to access international markets without the traditional barriers of cross-border trade. Furthermore, these platforms continuously evolve based on user feedback and technological advancements, incorporating new features like predictive analytics for inventory management, automated compliance checking, and integration with enterprise resource planning systems.

The success of Global Component Procurement Malls has created a virtuous cycle: as more buyers join these platforms, they attract more suppliers, which in turn increases component availability and competitive pricing, drawing even more buyers. This network effect has accelerated the adoption of these platforms across the electronics industry. Today, leading procurement malls host millions of components from thousands of verified suppliers worldwide, processing billions of dollars in transactions annually and becoming indispensable tools for electronics manufacturers across the spectrum.

Key Features and Benefits of Global Component Procurement Malls

Comprehensive Component Selection and Availability

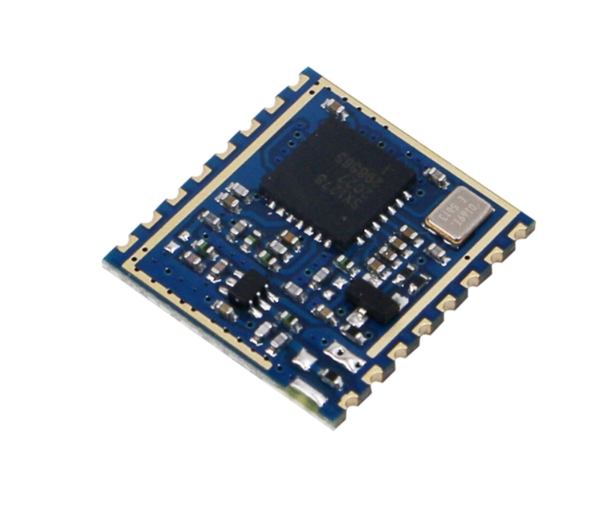

One of the most significant advantages of Global Component Procurement Malls is their unparalleled component selection. These platforms aggregate inventory from hundreds or even thousands of verified suppliers worldwide, creating a virtual supermarket for electronic components. Whether sourcing common resistors and capacitors or specialized processors and sensors, buyers can find virtually any component they need through a single platform. This comprehensive selection eliminates the need to search multiple distributor websites or contact numerous suppliers individually, saving valuable time and resources.

The scale of inventory available through these malls is staggering—leading platforms typically list hundreds of millions of component instances across countless part numbers and manufacturers. This extensive coverage is particularly valuable for companies working with legacy systems or specialized applications where specific components may be difficult to source through traditional channels. Additionally, many procurement malls specialize in hard-to-find or obsolete components, providing lifelines for manufacturers needing to maintain or repair older equipment where original components are no longer in production.

Beyond sheer volume, these platforms offer sophisticated tools for navigating their extensive inventories. Advanced search functionality allows engineers to find components based on technical specifications rather than just part numbers—a crucial capability when direct replacements aren’t available. Cross-referencing tools help identify alternative components with similar characteristics, while parametric search enables filtering based on specific technical requirements. These features transform what would otherwise be an overwhelming amount of information into a manageable and actionable resource for procurement decisions.

Transparent Pricing and Market Intelligence

Global Component Procurement Malls have brought unprecedented pricing transparency to the electronic components market. Unlike traditional distribution channels where pricing was often negotiated individually and varied significantly between customers, these platforms typically display clear pricing information available to all users. This transparency enables buyers to make informed decisions based on actual market prices rather than estimates or negotiated rates that may not reflect true market conditions.

The pricing models on these platforms vary but generally include real-time pricing from multiple suppliers for the same component, allowing for easy comparison shopping. Many platforms also provide historical pricing data, enabling buyers to identify trends and make purchasing decisions based on market direction rather than just current snapshot prices. Some advanced platforms even offer price forecasting based on machine learning algorithms that analyze multiple market factors—information that was previously available only to large corporations with dedicated market analysis teams.

Beyond basic pricing transparency, these malls provide valuable market intelligence that helps buyers optimize their procurement strategies. Features like inventory level indicators across multiple suppliers help assess market availability; lead time information assists in production planning; minimum order quantity displays prevent unexpected requirements; and real-time stock updates prevent orders for unavailable components. This comprehensive market intelligence transforms procurement from a reactive process to a strategic function that can significantly impact a company’s bottom line and operational efficiency.

Quality Assurance and Supply Chain Security

Perhaps the most critical concern in component procurement—especially in industries like aerospace, medical devices, and automotive where failure can have catastrophic consequences—is component authenticity and quality. Global Component Procurement Malls address this concern through sophisticated verification processes that go far beyond what individual companies can typically implement. Leading platforms employ multi-layered approaches to quality assurance including supplier verification programs; component testing services; documentation validation; and increasingly, blockchain-based provenance tracking.

Supplier verification is typically the first line of defense against counterfeit components. Reputable procurement malls implement rigorous supplier onboarding processes that include verification of business credentials; assessment of financial stability; evaluation of quality management systems; and review of customer feedback. Many platforms tier suppliers based on their verification level and performance history; providing clear indicators to buyers about supplier reliability. Some platforms even offer insurance or guarantees against counterfeit components; providing additional peace of mind for critical applications.

For additional security; many platforms offer value-added services like component testing; X-ray inspection; decapsulation; and functional testing—either performed by the platform itself or through certified third-party partners. These services provide physical verification of component authenticity and functionality; addressing one of the most significant risks in electronic component procurement. The comprehensive approach to quality assurance found in leading Global Component Procurement Malls has made them increasingly trusted sources for components—even for highly regulated industries with stringent quality requirements.

The Future Landscape: Emerging Trends in Component Procurement

Artificial Intelligence and Predictive Analytics

The integration of artificial intelligence is poised to take Global Component Procurement Malls to the next level of sophistication and utility. AI algorithms are already enhancing search functionality; making it easier for engineers to find exactly what they need based on incomplete information or performance requirements rather than specific part numbers. Machine learning systems can analyze historical purchasing patterns; market trends; and external factors like geopolitical developments or natural disasters to provide increasingly accurate predictions about component availability; pricing trends; and potential supply chain disruptions.

Looking forward; we can expect AI to play an even more significant role in automating routine procurement decisions while flagging anomalies that require human attention. Predictive inventory management systems will advise buyers on optimal ordering quantities and timing based on production schedules; market conditions; and lead time predictions. Natural language processing capabilities will enable more intuitive interactions with procurement platforms; allowing engineers to describe what they need in conversational language rather than technical specifications.

Perhaps most importantly; AI will enable increasingly sophisticated risk assessment across the supply chain. By analyzing data from thousands of transactions across multiple dimensions—supplier performance; geopolitical factors; transportation logistics; market dynamics—AI systems can identify potential vulnerabilities before they become critical issues. This predictive capability will be invaluable in an industry where supply chain disruptions can halt production lines and cost millions in lost revenue. As these AI systems mature; they’ll likely become indispensable tools for strategic sourcing decisions rather than just transactional platforms.

Blockchain for Provenance and Authenticity

Blockchain technology is emerging as a powerful solution to one of the most persistent challenges in component procurement: verifying authenticity throughout the supply chain. By creating immutable; transparent records of each component’s journey from manufacturer to end user; blockchain can virtually eliminate counterfeit components from entering legitimate supply chains. Several leading electronics manufacturers have already begun implementing blockchain-based provenance tracking for critical components; and this approach is gradually being integrated into Global Component Procurement Malls.

The implementation typically involves creating digital twins—blockchain tokens representing physical components—that are transferred between parties as components move through the supply chain. Each transaction is recorded on the blockchain; creating an auditable trail that verifies authenticity while protecting sensitive commercial information through appropriate privacy measures. This approach not only prevents counterfeiting but also simplifies compliance with regulatory requirements—particularly important in industries like aerospace; defense; and medical devices where component traceability is mandated.

Beyond anti-counterfeiting; blockchain enables new business models like component leasing rather than purchasing; facilitated by unambiguous ownership records. It also simplifies returns; repairs; and warranty claims by maintaining complete history records for individual components. As blockchain technology matures and becomes more widely adopted; we can expect it to become a standard feature of reputable Global Component Procurement Malls—particularly for high-value or safety-critical components where authenticity is non-negotiable.

Sustainability and Circular Economy Integration

The electronics industry faces increasing pressure to address its environmental impact—from resource extraction in manufacturing to electronic waste at end-of-life. Global Component Procurement Malls are uniquely positioned to facilitate more sustainable practices throughout the component lifecycle by enabling efficient reuse and recycling of electronic components. Several platforms have already begun incorporating sustainability features including carbon footprint calculations for shipments; identification of refurbished or recycled components; and tools for reselling surplus inventory.

The concept of a circular economy—where components are reused multiple times rather than discarded after single use—aligns perfectly with the multi-supplier; multi-buyer model of procurement malls. These platforms can efficiently match sellers of surplus or unused components with buyers who need them; reducing waste while providing cost savings. Similarly; they can facilitate the legitimate refurbishment and resale of components removed from retired equipment—a practice that was previously challenging due to difficulties in verifying quality and finding appropriate markets.

Looking forward; we can expect sustainability to become a central consideration rather than an afterthought in component procurement platforms. Features might include sustainability ratings for suppliers based on their environmental practices; automated calculation of carbon emissions reduction through component reuse; integration with take-back programs for end-of-life equipment; and tools for optimizing shipping routes to minimize environmental impact. As regulatory pressure increases and customer preferences shift toward more sustainable products; these features will become increasingly important differentiators for procurement platforms.

Conclusion

The emergence and evolution of Global Component Procurement Malls represent one of the most significant transformations in the electronics supply chain in decades. These platforms have democratized access to electronic components while bringing unprecedented efficiency; transparency; and security to procurement processes. By aggregating global supply into accessible digital marketplaces; they’ve eliminated traditional barriers that limited smaller companies’ access to essential components while providing all buyers with tools and information previously available only to industry giants.

The benefits extend far beyond convenience—these platforms have become essential tools for managing supply chain risk; optimizing costs; ensuring component quality; and ultimately maintaining competitive advantage in fast-moving electronics markets. The integration of emerging technologies like artificial intelligence; blockchain; and advanced analytics promises to further enhance these benefits while addressing longstanding industry challenges related to counterfeiting; supply chain visibility;and environmental sustainability.

As these platforms continue to evolve; we can expect them to become even more deeply integrated into product developmentand manufacturing processes—not just as purchasing channels but as strategic partners in supply chain management.Forward-thinking companies are already leveraging these platforms not just for cost savings but as sourcesof competitive advantage through superior supply chain resilienceand market intelligence.In this context;ICGOODFIND stands out as an exemplary platform that embodies these advancements;a comprehensive solution that connects businesses with verified global suppliers while providingthe toolsand insights needed tonavigate today’s complex electronics supply chain landscape.The futureof electroniccomponent procurementis undoubtedly digitalglobaland interconnected—and Global Component Procurement Mallsare leading thistransformation every step ofthe way.