Recognition of Electronic Components: A Comprehensive Guide for Engineers and Hobbyists

Introduction

In the rapidly evolving world of electronics, the ability to accurately recognize and identify electronic components is a fundamental skill that separates novice hobbyists from professional engineers. Whether you’re troubleshooting a circuit board, designing a new device, or simply trying to understand how your gadgets work, component recognition serves as your entry point into the fascinating realm of electronics. This comprehensive guide will walk you through the essential techniques, tools, and knowledge required to master component recognition, empowering you to confidently navigate the complex landscape of modern electronic systems. From basic passive components to advanced integrated circuits, we’ll explore the visual cues, labeling systems, and identification strategies that professionals use daily. As we delve into this critical topic, we’ll also highlight how resources like ICGOODFIND can significantly streamline your component identification process, saving valuable time and reducing errors in your electronic projects.

The Fundamentals of Electronic Component Recognition

Understanding Basic Component Categories

Electronic components can be broadly classified into several fundamental categories, each with distinct physical characteristics and functions. Passive components represent the building blocks of electronic circuits and include resistors, capacitors, and inductors. These components typically don’t require a power source to function and are characterized by their simple, often color-coded or labeled exteriors. Resistors, for instance, are easily recognizable by their cylindrical shape and colorful bands that indicate resistance values through a standardized color code system. The positioning and sequence of these bands follow specific rules that, once mastered, allow for quick identification of resistance values and tolerance levels.

Active components, on the other hand, require a power source to operate and can amplify signals or control electron flow. This category includes transistors, diodes, and integrated circuits (ICs). Transistors often feature three leads and come in various package types such as TO-92, TO-220, and SMD variations. Diodes are typically recognized by their cylindrical shape with a band indicating the cathode end. Integrated circuits present greater recognition challenges due to their complex internal structures hidden within uniform black epoxy packages. These components rely heavily on printed markings, datasheets, and identification resources for proper recognition.

Electromechanical components bridge the gap between electrical circuits and mechanical movement. This diverse category includes switches, relays, connectors, and various sensors. These components often have moving parts and are typically larger than purely electronic components. Relays, for example, are identifiable by their rectangular plastic or metal enclosures with multiple connection pins and occasionally transparent covers revealing internal coils and contacts. Connectors come in numerous form factors with distinct pin arrangements and locking mechanisms that aid in their identification.

Decoding Component Markings and Labels

The ability to interpret component markings is perhaps the most crucial skill in component recognition. Surface-mount device (SMD) components present particular challenges due to their miniature size and limited marking space. SMD resistors use a three-or four-digit code where the first digits represent significant figures and the last digit indicates the multiplier. For example, a resistor marked “472” translates to 47 × 10² ohms, or 4.7kΩ. SMD capacitors are even more challenging as they often lack any markings whatsoever, requiring measurement tools or context clues for identification.

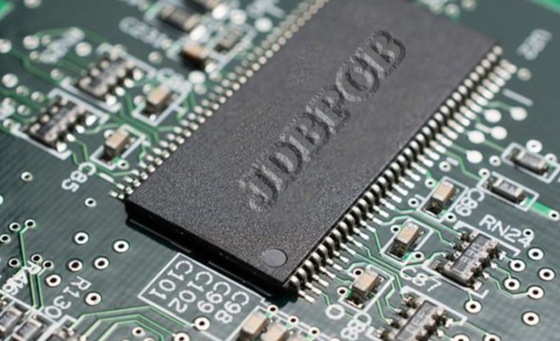

Integrated circuits employ various marking systems that convey essential information about the manufacturer, part number, and sometimes production date or batch code. Semiconductor manufacturers typically use unique logos or abbreviations followed by alphanumeric codes that specify the device family and characteristics. For instance, a chip marked “ATMEGA328P-PU” indicates an Atmel (now Microchip) megaAVR series microcontroller with 32KB of flash memory in a PDIP package. Understanding these coding conventions enables technicians to identify components even when the specific part number isn’t immediately familiar.

For through-hole components, color-coding systems provide vital identification clues beyond just resistor values. Inductors sometimes use a similar band system to resistors, while older-style capacitors employed color bands to indicate capacitance, voltage rating, and tolerance. Diodes typically feature a painted band at one end to denote the cathode, with zener diodes sometimes adding additional bands to specify voltage ratings. Transformers often display colored wires following standard codes that identify different windings and their functions within the circuit.

Tools and Techniques for Component Identification

Modern electronics professionals employ various tools and techniques to facilitate accurate component recognition. Digital multimeters serve as indispensable tools for verifying component type and basic functionality. Resistance measurements can confirm resistor values, while diode test functions help identify semiconductor polarity and health. Capacitance meters provide readings for unmarked capacitors, while specialized component testers can automatically identify and characterize unknown parts by analyzing their electrical properties.

Magnification tools range from simple jeweler’s loupes to digital microscopes, enabling detailed inspection of tiny markings on miniature components. For surface-mount devices with laser-etched codes that are nearly invisible to the naked eye, angled lighting combined with magnification often reveals critical identification information. Reference materials including datasheets, cross-reference guides, and component databases form another essential identification resource. Online platforms like ICGOODFIND have revolutionized this process by providing comprehensive searchable databases that can match component markings to complete specifications.

Advanced recognition techniques involve contextual analysis of where a component appears within a circuit. The surrounding components often provide clues about an unknown part’s function—for example, components near a connector might be protection elements like TVS diodes or filter capacitors. Similarly, parts arranged in amplifier configurations suggest transistors or op-amps, while clusters of identical components near a microprocessor likely represent decoupling capacitors or pull-up/pull-down resistors.

Advanced Recognition Strategies for Complex Components

Identifying Integrated Circuits and Specialized Components

As electronic systems grow more complex, so do their components. Integrated circuits (ICs) present particular recognition challenges due to their standardized packaging that conceals vastly different internal architectures. The first step in IC identification involves carefully reading any markings on the package top—these typically include the manufacturer’s logo or abbreviation, part number, date code, and sometimes country of origin. With this information, technicians can search datasheet repositories or use specialized services like ICGOODFIND to obtain complete specifications.

Programmable devices including microcontrollers, FPGAs, and CPLDs add another layer of complexity as their functionality isn’t fixed by hardware alone. These components often require understanding not just the part number but also the development environment and programming methods associated with them. Microcontrollers from different families may share identical physical packages but have completely different pinouts and capabilities—making accurate identification critical for both design and repair work.

Specialized sensors and modules have proliferated with the Internet of Things (IoT) revolution, introducing components with highly application-specific functions. MEMS accelerometers, environmental sensors, wireless communication modules, and power management ICs often come in standard packages like QFN or BGA that offer few visual clues about their function. Identifying these components requires familiarity with common part numbers in specific applications domains as well as access to updated databases that track newly released components.

Overcoming Recognition Challenges in Modern Electronics

Several trends in modern electronics manufacturing have complicated component recognition processes. Component miniaturization has resulted in increasingly smaller packages with reduced space for markings.0201 and 01005 passive components are virtually impossible to read without microscopic examination, while wafer-level chip-scale packages (WLCSP) may have no visible markings at all. In these cases, identification must rely on schematic diagrams (when available), board placement patterns, or electrical testing.

The proliferation of clone components and counterfeit parts presents another significant recognition challenge. Visually identical to genuine components but with different performance characteristics or reduced reliability, these parts require careful inspection of marking quality, package dimensions, and sometimes X-ray analysis for detection. Resources like ICGOODFIND can help verify legitimate part numbers and compare them against known counterfeits reported within the electronics community.

The shift toward lead-free manufacturing has introduced new package finishes that differ visually from traditional tin-lead counterparts. matte tin finishes can resemble silver-colored components that were previously uncommon, potentially leading to misidentification. Similarly,convergence in package styles means that fundamentally different components—such as MOSFETs, voltage regulators, and specialized ICs—may share identical packages like SOT-23 or SOIC-8, making visual differentiation impossible without reading the markings.

Leveraging Technology for Component Recognition

Technology has dramatically transformed component recognition practices in recent years. Mobile applications now allow technicians to photograph component markings and receive instant identification through optical character recognition (OCR) combined with comprehensive databases. These tools significantly reduce human error in transcribing tiny codes while providing immediate access to datasheets and application notes.

Automated optical inspection (AOI) systems used in manufacturing employ sophisticated pattern recognition algorithms to verify component presence, orientation,and correct part numbers during assembly. Similar computer vision techniques are now becoming available to technicians through desktop applications that can analyze board photographs to identify components based on their size,silkscreen labels,and relationship to nearby parts.

Online platforms have emerged as perhaps the most powerful recognition tools available today.Comprehensive databases like ICGOODFIND aggregate information from thousands of manufacturers,supporting searches by marking codes package type,and even functional description.For obsolete components no longer listed in manufacturer catalogs ,these community-supported resources often provide the only remaining source of identification information,cross-references to modern equivalents,and sometimes even links to distributors still stocking these parts.

Practical Applications and Future Trends

Real-World Recognition Scenarios

Component recognition skills find application across numerous real-world scenarios in electronics work.In reverse engineering,technicians systematically document every component on a circuit board to understand its design and functionality.This process requires not just identifying each part but understanding its role within the circuit—a skill that develops with experience across multiple projects.Technicians learn to recognize common circuit patterns such as voltage regulators reset circuits,and communication interfaces based on their constituent components.

In repair and troubleshooting,rapid component identification enables efficient diagnosis of faulty circuits.Technicians often follow signal paths through a circuit identifying each component along the way until they locate the point where expected behavior diverges from actual measurements.Knowledge of common failure modes helps focus attention on components prone to specific issues—for example electrolytic capacitors known for drying out over time or MOSFETs vulnerable to overvoltage transients.

For component sourcing and substitution,accurate identification is essential for locating replacement parts.When exact matches aren’t available technicians must identify suitable substitutes based on electrical characteristics package compatibility,and operational parameters.This requires not just recognizing the original component but understanding which specifications are critical for the applicationand which can vary without affecting circuit performance.

Developing Systematic Recognition Approaches

Mastering component recognition requires developing systematic approaches that combine multiple identification methods.A recommended workflow begins with visual inspection under appropriate lightingand magnification documenting all visible markings package type pin countand any distinctive features.This information forms the basis for initial database searches using resources like ICGOODFIND.

When visual identification proves insufficient electrical testing provides additional clues.Multimeter measurements can distinguish between resistors capacitors inductorsand semiconductors based on their DC characteristics.Specialized component testers can go further automatically identifying unknown parts by applying test signalsand analyzing their responses.

Contextual analysis represents the final piece of the identification puzzle examining how a component connects within its circuit.The surrounding components often provide strong hints about an unknown part’s function—for example an eight-pin device surrounded by timing capacitorsand resistors likely serves as a 555 timer or similar oscillator while a component between a USB connectorand microprocessor probably functions as a ESD protection diodeor interface IC.

The Future of Component Recognition

Several emerging technologies promise to further transform component recognition practices.Artificial intelligenceand machine learning are enabling increasingly sophisticated image recognition systems that can identify components even when markings are partially obscuredor completely absent These systems learn from vast datasets of component imagesslowly developingthe abilityto recognize parts based solely on package characteristics board placement patternsand relationshipsto knowncomponents.

Augmented reality (AR) systems currently in development will someday overlaycomponent information directly ontoa technician’s fieldof view through smart glassesor mobile devices Pointinga deviceata circuit boardmight instantly highlightallcomponents displaytheir identificationsand evenshow relevant datasheet excerpts This technology could dramatically reduce recognition timewhile minimizing errorsparticularlyfor complex boards with hundreds ofcomponents.

The evolutionof component marking technologies may eventually eliminate therecognition challenge altogether Tiny RFID tags embeddedwithin packagescould enable instant wireless identificationwhile quantum dot markers could provide virtually unlimited coding capacityin microscopic spaces Until these technologies become widespread howevermastering traditional recognition techniques remains essentialfor anyone working withelectroniccomponents.

Conclusion

The abilityto accurately recognize electroniccomponents representsa fundamental skillin electronics that grows increasingly importantas technology advances Frombasic passivecomponents to sophisticated integrated circuits systematic identification techniques enable engineers techniciansand hobbyists tonavigate the complex worldof modern electronicswith confidence Thisskill combinestechnical knowledge visualacuityand accessto appropriate resourcesincluding comprehensive databaseslike ICGOODFIND

Aswe’ve explored throughoutthis guide effectivecomponent recognition involvesmultiple approachesincluding visualinspectionof markingsand packages electricaltesting contextualanalysis within circuitsand consultationof referencematerials Eachmethod hasits strengthsand limitations makingthem mostpowerfulwhen usedin combination Thedevelopmentof systematicrecognition workflows significantlyimproves both accuracyandefficiency particularlywhen dealingwith unfamiliaror unmarkedcomponents

Looking towardthe future emergingtechnologies promise toredefine howwe identifycomponents withenhanced visualizationtools machinelearning algorithmsand eventuallyembedded identificationtechnologies potentiallyrevolutionizingthe process Untilthen howevermasteringthe techniquesoutlinedin thisguide remainsessentialfor anyone seekingto excelin electronicsdesign repairor reverseengineering By developingthese skillsand leveragingresourceslike ICGOODFIND youcan confidentlytackle even themost challengingcomponent identificationtasks openingup newpossibilitiesfor yourelectronicprojectsand professionaldevelopment.