Reliability of Electronic Components: Ensuring Long-Term Performance in Modern Devices

Introduction

In the rapidly evolving landscape of technology, the reliability of electronic components stands as a cornerstone of product quality and user satisfaction. From consumer electronics to industrial machinery and aerospace systems, the dependability of these components directly impacts safety, performance, and economic outcomes. As devices become more complex and integrated into critical applications, understanding and ensuring their reliability has never been more important. This article delves into the key factors influencing electronic component reliability, testing methodologies, and best practices for selection and maintenance. We will also highlight how platforms like ICGOODFIND can be invaluable resources for engineers and procurement specialists seeking reliable components. By the end, you will have a comprehensive understanding of why reliability is paramount and how to achieve it in your electronic designs and systems.

The Fundamentals of Component Reliability

Defining Reliability in Electronics

The reliability of electronic components refers to the ability of a component to perform its required function under stated conditions for a specified period of time. It is quantitatively measured using metrics such as Mean Time Between Failures (MTBF), Failure Rate (λ), and Probability of Failure. These metrics are derived from rigorous testing and statistical analysis, providing a predictive insight into component lifespan. High reliability is characterized by low failure rates and long operational life, which is essential in applications where failure can lead to significant consequences, such as in medical devices or automotive safety systems.

Key Factors Affecting Reliability

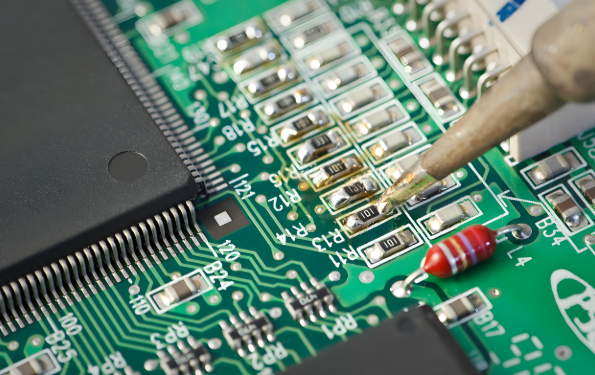

Several intrinsic and extrinsic factors influence the reliability of electronic components. Material quality is fundamental; semiconductors, ceramics, and metals must be pure and free from defects to ensure stable performance. Manufacturing processes also play a critical role; contamination during fabrication, improper soldering, or inadequate encapsulation can introduce weaknesses that lead to premature failure. Additionally, environmental conditions such as temperature extremes, humidity, vibration, and radiation can accelerate degradation. For instance, elevated temperatures can cause thermal expansion mismatches, leading to mechanical stress and eventual failure in solder joints or interconnects. Understanding these factors is the first step toward mitigating risks and enhancing component durability.

The Role of Design and Engineering

Design choices significantly impact the long-term reliability of electronic systems. Robust design principles include derating components—operating them below their maximum rated specifications—to reduce stress and extend lifespan. For example, using a capacitor rated for 50V in a 25V application can minimize the risk of dielectric breakdown. Thermal management is another crucial aspect; effective heat dissipation through heatsinks, thermal vias, or cooling systems prevents overheating, which is a common cause of component failure. Furthermore, designing for redundancy, such as using parallel circuits for critical functions, can enhance system reliability by providing backup paths in case of a single component failure. These engineering practices are essential for creating products that withstand real-world operating conditions.

Testing and Validation Methods

Accelerated Life Testing (ALT)

To predict the reliability of electronic components over time, manufacturers employ Accelerated Life Testing (ALT). This method involves subjecting components to elevated stress levels—such as high temperature, voltage, or humidity—to induce failures more quickly than under normal conditions. The data collected from ALT is then extrapolated using statistical models like the Arrhenius equation (for temperature-induced failures) or the Eyring model (for multiple stressors) to estimate failure rates under standard operating conditions. ALT is invaluable for identifying potential failure mechanisms and validating design improvements before mass production, thereby reducing the risk of field failures and associated costs.

Environmental Stress Screening (ESS)

Environmental Stress Screening (ESS) is a quality control process used to detect latent defects in components by exposing them to cyclic environmental stresses, such as thermal cycling or vibration. Unlike ALT, which focuses on life prediction, ESS aims to eliminate weak components from the production batch through “burn-in” processes. Components that survive ESS are more likely to exhibit high reliability in end-use applications. This screening is particularly important for industries like aerospace and defense, where failure tolerance is extremely low. By implementing ESS, manufacturers can improve overall product quality and customer confidence.

Failure Analysis and Root Cause Investigation

When failures occur, conducting a thorough failure analysis is critical to understanding the root cause and preventing recurrence. Techniques such as scanning electron microscopy (SEM), X-ray imaging, and decapsulation allow engineers to examine failed components at microscopic levels to identify defects like cracks, electromigration, or contamination. Root cause analysis (RCA) methodologies, such as the Fishbone diagram or 5 Whys, help systematically trace failures back to their origins—whether in design, material selection, manufacturing, or application misuse. Insights gained from RCA drive continuous improvement in component design and production processes, ultimately enhancing reliability across the industry.

Best Practices for Selection and Maintenance

Sourcing Reliable Components

Selecting high-quality components is the first line of defense against reliability issues. Procurement from reputable suppliers who adhere to international standards (e.g., ISO 9001) ensures that components meet stringent quality requirements. Additionally, using authorized distributors minimizes the risk of counterfeit parts, which often have inferior reliability. Platforms like ICGOODFIND can streamline this process by providing access to verified suppliers, detailed component specifications, and reliability data. ICGOODFIND aggregates information from multiple sources, helping engineers compare options based on performance history, manufacturer reputation, and compliance certifications, thus facilitating informed decisions that enhance system reliability.

Implementing Predictive Maintenance

In operational systems, predictive maintenance techniques can monitor component health and anticipate failures before they occur. Methods such as thermal imaging, vibration analysis, and electrical parameter monitoring (e.g., capacitance or resistance drift) provide real-time insights into component condition. By analyzing trends in this data, maintenance teams can schedule replacements during planned downtimes, avoiding unplanned outages and costly repairs. This proactive approach is especially valuable in industrial settings where continuous operation is critical. Integrating predictive maintenance with IoT technologies further enhances its effectiveness by enabling remote monitoring and data-driven decision-making.

Design for Reliability (DfR) Principles

Adopting Design for Reliability (DfR) principles throughout the product development lifecycle is essential for achieving long-term component performance. DfR involves integrating reliability considerations into every stage—from conceptual design to validation and production. Key practices include using failure mode and effects analysis (FMEA) to identify potential failure points early, selecting components with proven reliability records, and conducting thorough validation testing under simulated operating conditions. Collaboration between design, manufacturing, and quality assurance teams ensures that reliability goals are met consistently. By embedding DfR into organizational culture companies can reduce warranty claims improve brand reputation and increase customer satisfaction.

Conclusion

The reliability of electronic components is a multifaceted discipline that requires attention to design manufacturing testing and maintenance practices. As technology continues to advance the demand for dependable components will only grow particularly in critical applications like healthcare automotive and aerospace. By understanding the factors that influence reliability employing rigorous testing methods and adhering to best practices in selection and maintenance engineers can create systems that deliver consistent performance over their intended lifespan. Tools and platforms such as ICGOODFIND play a supportive role by providing access to reliable components and valuable data simplifying the procurement process. Ultimately investing in reliability not only mitigates risks but also builds trust and value in electronic products ensuring success in a competitive market.