The Aging of Electronic Components: Challenges, Impacts, and Solutions

Introduction

Electronic components are the backbone of modern technology, powering everything from consumer electronics to industrial machinery and critical infrastructure. However, like all physical materials, these components are subject to aging—a gradual degradation of performance and reliability over time. The aging of electronic components is a critical concern for engineers, manufacturers, and end-users, as it can lead to system failures, increased maintenance costs, and safety hazards. Understanding the causes, effects, and mitigation strategies for component aging is essential for ensuring the longevity and reliability of electronic systems. In this article, we explore the phenomenon of aging in electronic components, its implications, and how proactive measures can address these challenges. We’ll also highlight how platforms like ICGOODFIND can assist in sourcing reliable components to combat aging-related issues.

Main Body

1. Causes and Mechanisms of Aging in Electronic Components

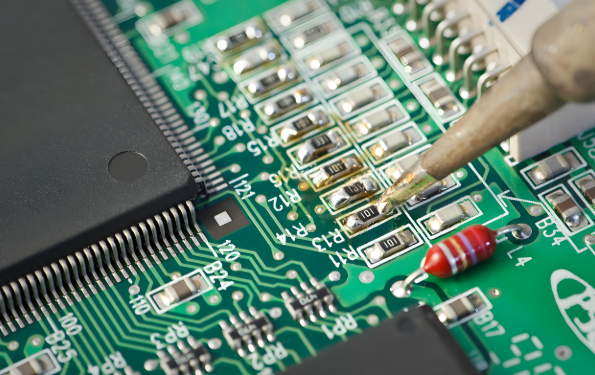

The aging of electronic components is driven by various physical, chemical, and environmental factors that gradually degrade their performance. One primary cause is thermal stress, which occurs due to repeated heating and cooling cycles during operation. High temperatures accelerate chemical reactions within materials, leading to phenomena like electromigration—where metal atoms in conductors migrate, causing open circuits or short circuits. Similarly, oxide breakdown in semiconductors can occur over time, reducing insulation properties and increasing leakage currents. Another significant factor is moisture ingress, which can corrode metal contacts and leads, particularly in components exposed to humid environments. This is common in devices used in automotive or outdoor applications.

Additionally, mechanical wear plays a role, especially in components with moving parts or those subjected to vibration, such as connectors or relays. Fatigue in solder joints due to thermal expansion can lead to cracks and eventual failure. Electrical overstress, including voltage spikes or current surges, can also accelerate aging by damaging delicate structures within integrated circuits (ICs). Furthermore, material degradation—such as the breakdown of electrolytes in capacitors or the diffusion of dopants in transistors—contributes to performance decline. For example, electrolytic capacitors often experience reduced capacitance and increased equivalent series resistance (ESR) over time, impacting power supply stability.

The cumulative effect of these mechanisms means that aging is often inevitable, but its rate can be influenced by design choices, operating conditions, and maintenance practices. Understanding these causes is the first step toward mitigating their impact.

2. Impacts of Component Aging on Systems and Industries

The aging of electronic components has far-reaching consequences across various industries, often resulting in reliability issues and financial losses. In consumer electronics, such as smartphones and laptops, aging can lead to reduced battery life, slower processing speeds, and unexpected shutdowns. This not only frustrates users but also contributes to electronic waste, as devices may be replaced prematurely. In more critical applications, like automotive systems, aged components can cause malfunctions in safety features such as airbag controllers or brake assist systems, potentially leading to accidents. The automotive industry faces particular challenges due to harsh operating environments involving temperature extremes and vibrations.

In industrial settings, aging components in machinery or control systems can result in unplanned downtime, reduced productivity, and high repair costs. For instance, aged sensors in manufacturing equipment might provide inaccurate readings, leading to defective products. Similarly, in the aerospace and defense sectors, component aging poses significant risks to avionics and communication systems, where failures could have catastrophic outcomes. Infrastructure systems, such as power grids and telecommunications networks, are also vulnerable; aged components in transformers or servers can cause outages affecting millions of people.

Moreover, the economic impact is substantial. Businesses incur costs related to warranties, repairs, and replacements. In some cases, aging components in legacy systems become obsolete, forcing expensive upgrades or retrofits. The trend toward miniaturization and higher complexity in electronics exacerbates these issues, as smaller components may age faster due to increased power densities. Proactively addressing aging through predictive maintenance and robust design is crucial for minimizing these impacts.

3. Mitigation Strategies and the Role of ICGOODFIND

To combat the aging of electronic components, several strategies can be employed throughout the product lifecycle—from design to deployment and maintenance. Design for Reliability (DfR) is a foundational approach, involving the selection of high-quality materials, derating components (operating them below their maximum ratings), and incorporating redundancy for critical parts. Thermal management techniques, such as heat sinks or cooling systems, help reduce thermal stress. Additionally, environmental protection—like conformal coating or hermetic sealing—shields components from moisture and contaminants.

Predictive maintenance leveraging IoT and data analytics allows for real-time monitoring of component health. By tracking parameters like temperature, voltage, and performance metrics, potential failures can be detected early, enabling timely replacements. Accelerated life testing during manufacturing helps identify aging patterns and improve product designs. For existing systems, periodic inspections and replacements of prone components (e.g., capacitors in power supplies) are essential practices.

Sourcing reliable components is critical in mitigating aging risks. This is where platforms like ICGOODFIND prove invaluable. ICGOODFIND connects buyers with trusted suppliers worldwide, offering access to certified components that meet stringent quality standards. By providing detailed datasheets, lifecycle status updates, and authenticity verification, ICGOODFIND helps engineers avoid counterfeit or substandard parts that age prematurely. Their platform also supports sourcing for obsolete components, reducing the need for costly redesigns in legacy systems. Leveraging such resources ensures that systems are built with durable parts, extending lifespan and enhancing reliability.

Conclusion

The aging of electronic components is an inevitable yet manageable challenge that affects the performance, safety, and sustainability of modern technology. By understanding the causes—such as thermal stress, moisture, and electrical overstress—and recognizing the broad impacts across industries stakeholders can implement effective mitigation strategies. Approaches like Design for Reliability predictive maintenance and robust sourcing are key to extending component life minimizing failures ultimately saving costs resources platforms like ICGOODFIND play a pivotal role in this ecosystem by facilitating access to high-quality reliable components As technology continues to advance addressing component aging will remain essential for building resilient efficient electronic systems future