X-Fab’s Dr. Ulrich Bretthauer warns ending 150mm CMOS processes creates structural industry risks, not just product changes.

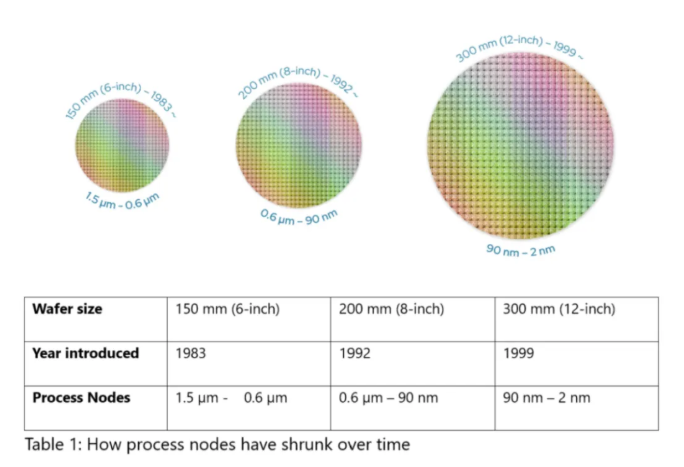

Automotive and industrial electronics makers, reliant on stable IC supplies, face disruptions as foundries halt 150mm production. This forces redesigns and impacts strategies, catching many off-guard with sudden EOLs for 0.6µm+ mature nodes (critical for analog/mixed-signal ICs). High maintenance costs and material issues drive shutdowns, leaving clients just 6-12 months to switch nodes.

Most shift to 350nm/180nm on 200mm wafers (over sub-130nm on 300mm) for balanced efficiency, low development costs, and mature 350nm performance (fast launches, strong analog/high-voltage capabilities).

200mm 350nm/180nm avoids 300mm’s small-batch inefficiency and 150mm’s MOQ issues. >90nm nodes made up 38% of Q3 2023 output, with a robust 200mm chain. 350nm offers long lifecycles, fitting analog/MEMS systems and basic MCUs. X-Fab’s "X-Chain" and European supply security back long-term 350nm+ commitments, ideal for analog ASICs (high-voltage/low-noise support).

Mature-node ASIC users need urgent action; X-Fab’s 200mm 350nm solution is a robust, cost-effective alternative.

ICgoodFind: 150mm closures risk the industry, with 200mm 350nm as a key replacement.