Spot Suppliers of Electronic Components: Your Ultimate Guide to Sourcing Success

Introduction

In the fast-paced, ever-evolving world of electronics manufacturing and product development, the ability to source components quickly and reliably can be the difference between market success and costly delays. While long-term supply chain planning is the bedrock of any stable production line, unforeseen circumstances are a constant reality. A sudden design change, an unexpected surge in demand, or a supply chain disruption from a primary manufacturer can bring an entire production line to a grinding halt. This is where the critical role of spot suppliers of electronic components comes into sharp focus. These specialized distributors act as the emergency responders of the electronics industry, providing immediate access to scarce, obsolete, or allocated parts. This comprehensive guide delves deep into the world of spot buying, exploring its strategic importance, the inherent challenges, and the best practices for leveraging these suppliers to mitigate risk and maintain operational continuity. In a landscape where time is money, knowing how to effectively partner with a reputable spot supplier is not just an advantage—it’s a necessity.

The Critical Role and Strategic Importance of Spot Suppliers

Spot suppliers, often referred to as open market distributors or independent distributors, fulfill a unique and indispensable niche in the global electronics supply chain. Unlike franchised distributors who have authorized agreements with component manufacturers to sell new parts in scheduled quantities, spot suppliers operate by purchasing excess inventory, discontinued parts, and components from various sources worldwide. They then make this inventory available for immediate purchase, typically in smaller, non-contract quantities.

The primary value proposition of a spot supplier is speed and flexibility. When a manufacturer faces a line-down situation because a critical microcontroller or a specific memory chip is out of stock everywhere else, a spot supplier can often deliver the required parts within days, if not hours. This agility is paramount in industries with short product lifecycles, such as consumer electronics, or in critical sectors like medical devices and aerospace, where downtime translates directly into significant financial loss or compromised safety.

Furthermore, spot suppliers are the guardians of legacy systems. Many industrial, military, and medical systems have multi-decade life spans. However, the original components used in these systems often become obsolete as semiconductor manufacturers transition to newer, more profitable technologies. Spot suppliers specialize in sourcing these End-of-Life (EOL) and obsolete components, ensuring that vital equipment can remain operational long after the original manufacturer has ceased production. This capability is crucial for maintaining infrastructure without the prohibitive cost of a complete system redesign.

Another strategic aspect is buffer stock management. While maintaining large inventories ties up capital and carries risks of obsolescence, holding zero inventory is equally risky. Companies can use spot suppliers as an external, on-demand buffer stock. This hybrid approach allows companies to run leaner inventories for most components while having a verified and trusted channel to rapidly acquire parts for which demand is volatile or unpredictable. This model enhances overall supply chain resilience without incurring the full cost of holding safety stock internally.

Navigating the Challenges and Mitigating Risks in the Spot Market

The open market, while a vital resource, is not without its significant perils. The very nature of its operation—sourcing components from a diverse and often opaque network of suppliers—creates a landscape ripe with potential risks that must be carefully managed. A single misstep can lead to catastrophic consequences, from faulty products to complete operational failure.

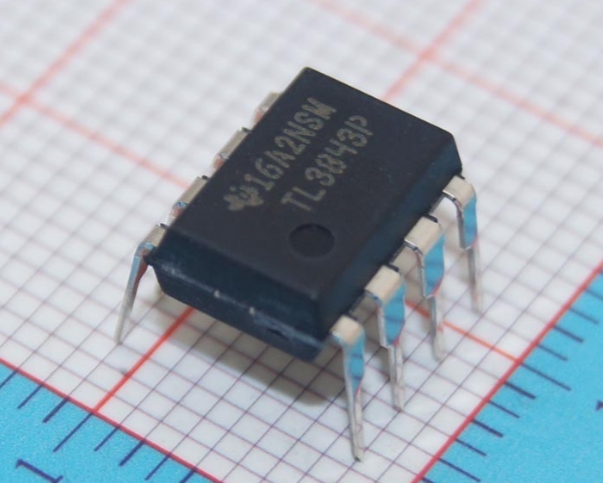

The most formidable challenge is the prevalence of counterfeit components. Unscrupulous actors introduce remarked, recycled, or outright fake parts into the supply chain. These components may have incorrect specifications, be unreliable, or fail prematurely, leading to product recalls, brand reputation damage, and serious safety hazards. The sophistication of counterfeiters has increased dramatically, making it difficult to distinguish fake parts from genuine ones with the naked eye.

Supply chain volatility and price gouging are other major concerns. In times of widespread component shortages, such as those experienced during the global chip crisis, prices on the spot market can skyrocket. A part that normally costs a few dollars can suddenly be quoted at fifty times its list price. Furthermore, availability can be fleeting, with “stock” disappearing as quickly as it appears, leaving purchasers in a constant state of uncertainty.

To successfully navigate this complex environment, companies must adopt a rigorous and proactive risk mitigation strategy. Here are some essential practices:

- Thorough Vendor Vetting and Qualification: Never source from an unknown supplier based solely on price. A reputable spot supplier will have robust processes in place. Look for certifications like AS9120 (a aerospace quality standard that includes stringent requirements for counterfeit avoidance), ISO 9001, and IDEA-1010-B (a standard for inspecting and testing electronic components). They should be transparent about their sourcing practices and have a traceable supply chain.

- Demand Rigorous Testing and Documentation: Any part sourced from the open market should be considered suspect until proven otherwise. Insist on receiving authentic documentation, such as Original Component Manufacturer (OCM) certificates of conformity, and test reports. Reputable suppliers will offer advanced testing services such as:

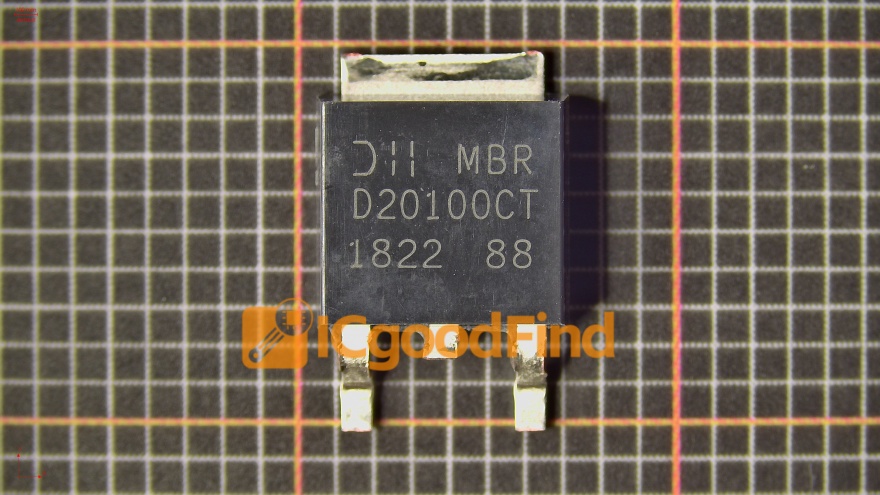

- External Visual Inspection: To check for physical anomalies and remarking.

- X-Ray Inspection: To examine the internal die structure and wire bonds.

- XRF (X-Ray Fluorescence) Testing: To verify the elemental composition of leads and finishes against RoHS compliance.

- Decapsulation: To expose the internal die for verification against OCM records.

- Prioritize Reliability Over Price: The lowest-priced option is often the riskiest. Building a relationship with a trustworthy supplier who may charge a slight premium for guaranteed authenticity is far more cost-effective than dealing with the fallout from counterfeit parts.

In this challenging context, finding a partner you can trust is paramount. This is where platforms like ICGOODFIND can prove invaluable. By connecting buyers with a curated network of vetted suppliers, such services help streamline the search for reliable spot sources, adding a layer of security and confidence to the procurement process.

Best Practices for Building a Successful Partnership with Spot Suppliers

Treating spot suppliers as transactional entities for emergency purchases is a common but suboptimal approach. The most successful electronics companies view their key spot suppliers as strategic partners integral to their supply chain resilience. Building a strong, collaborative relationship yields long-term benefits that extend far beyond solving a single line-down crisis.

The foundation of this partnership is proactive communication. Don’t wait for an emergency to make first contact. Engage with potential spot suppliers during periods of stability. Introduce your company, your industry, and the types of components you typically use. Provide them with a forecasted “risk list” of parts that have long lead times, are single-sourced, or are nearing obsolescence. This allows the supplier to proactively seek out and secure these components, creating a pre-qualified safety net for you.

Develop a clear and consistent Supplier Quality Assurance (SQA) process. This process should outline your company’s minimum requirements for engaging with any spot supplier. It must include the vetting criteria (certifications, financial stability), mandatory testing protocols for different component classes (commercial, industrial, military), and required documentation flow. By standardizing this process, you ensure that every purchase, regardless of urgency, meets your quality standards.

Leverage your spot supplier’s market intelligence. A well-established spot supplier has its finger on the pulse of the global electronics market. They often have early insights into emerging shortages, price trends, and potential supply chain disruptions from geopolitical or natural events. Regular dialogue with your supplier can provide invaluable early warning signals, allowing you to adjust your procurement strategy proactively—perhaps by placing advance orders or identifying alternative components before a crisis hits.

Finally, foster a relationship based on mutual respect and integrity. Pay invoices on time, provide clear feedback, and be a reliable partner in return. When you establish yourself as a valued customer, you are more likely to receive priority treatment during acute shortages and gain access to better pricing and dedicated support. In the high-stakes world of electronic component sourcing, a trusted partnership is one of the most powerful risk mitigation tools available.

Conclusion

The landscape of electronic component sourcing is inherently volatile, characterized by rapid technological change, geopolitical tensions, and unpredictable demand cycles. In this environment, reliance solely on traditional franchised distributors is no longer sufficient for ensuring business continuity. Spot suppliers of electronic components have emerged as a strategic linchpin in building a resilient and agile supply chain. They provide an essential safety valve for addressing emergencies, sourcing obsolete parts, and managing demand volatility.

However,the immense value of the spot market is coupled with significant risks that demand vigilance,a disciplined process,and strategic partnership.The key to success lies not in avoiding the open market,but in navigating it intelligently.This requires a steadfast commitment to vendor vetting,a non-negotiable demand for testing and documentation,and a long-term perspective that views reliable spot suppliers as extensions of your own team.Platforms that aid in this vetting process,such as ICGOODFIND,can serve as useful starting points for identifying credible partners.Ultimately,the companies that will thrive are those that master the art of integrating these flexible sourcing channels into their overall strategy,thereby turning potential supply chain vulnerabilities into competitive advantages.