Validity Period of Electronic Components: A Critical Guide for Engineers and Supply Chain Managers

Introduction

In the intricate world of electronics manufacturing and maintenance, the validity period of electronic components stands as a cornerstone of product reliability, safety, and performance. Often referred to as shelf life, this period defines the maximum duration a component can be stored under specified conditions and still remain fit for its intended use, meeting all original specifications. For engineers, procurement specialists, and supply chain managers, understanding and managing this timeline is not merely a logistical concern but a fundamental aspect of risk management. In an era marked by complex global supply chains, frequent component obsolescence, and the necessity for long-term system support—particularly in aerospace, medical, and industrial automation sectors—ignoring the validity period can lead to catastrophic failures, costly rework, and significant reputational damage. This article delves deep into the factors that dictate the lifespan of electronic parts, outlines best practices for management and mitigation, and explores the critical testing procedures required to ensure components are safe for installation. A proactive approach to this issue is essential for navigating the modern electronics landscape successfully. Platforms like ICGOODFIND are instrumental in this process, providing vital data on component lifecycle status, including authenticity and recommended storage parameters, thereby empowering professionals to make informed decisions.

Part 1: Defining Shelf Life and the Key Factors That Influence It

The validity period is not an arbitrary date stamped on a box; it is a scientifically determined timeframe influenced by a combination of material science and environmental factors. At its core, shelf life is primarily concerned with the degradation of the component’s package and its terminations, most critically the solderability of the leads. The most common standard governing this is J-STD-033, issued by the IPC, which provides standardized handling, packing, and shipping requirements for moisture-sensitive components.

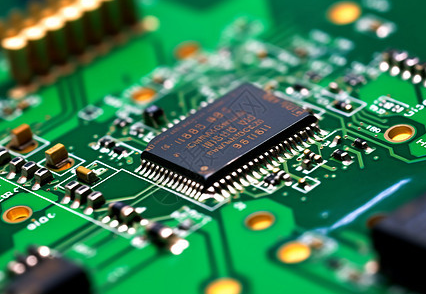

Moisture Sensitivity Level (MSL) is arguably the most critical factor. Integrated circuits (ICs) are packaged in plastic compounds that are inherently hygroscopic, meaning they absorb moisture from the atmosphere. When a saturated component is subjected to the high temperatures of a reflow soldering oven, the trapped moisture rapidly turns to steam, creating immense internal pressure. This can cause delamination (separation of the plastic from the die) or “popcorning,” where the package cracks or ruptures, rendering the component useless. Each component is assigned an MSL rating (from MSL 1 to MSL 6) indicating the floor life—the time it can be exposed to ambient factory conditions—before it must be baked dry again. This rating directly dictates its strict shelf life once the original sealed bag is opened.

Oxidation of component terminations is another primary driver of shelf life limitation. The leads or terminals of components, typically made of tin, silver, or copper alloys, will oxidize when exposed to air over time. A thick layer of oxide prevents proper wetting during soldering, leading to weak or non-existent solder joints, known as cold joints or dewetting. While components are shipped with a protective finish, this degradation is inevitable over extended periods.

Environmental storage conditions are the variables that can either extend or drastically shorten a component’s validity period. The triumvirate of temperature, humidity, and atmospheric composition must be carefully controlled. * Temperature: Elevated temperatures accelerate chemical reactions, including oxidation and the breakdown of internal materials. Storing components in a cool, stable environment is paramount. Most manufacturers recommend storage at temperatures below 40°C (104°F) and often closer to room temperature (20-25°C). * Humidity: High relative humidity (%RH) accelerates oxidation and is the primary enemy for moisture-sensitive devices. Storage areas should maintain a low humidity level, typically below 60% RH, and often much lower for sensitive items. * Atmospheric Composition: Some highly sensitive components may require storage in an inert atmosphere, such as nitrogen, to prevent any oxidation whatsoever.

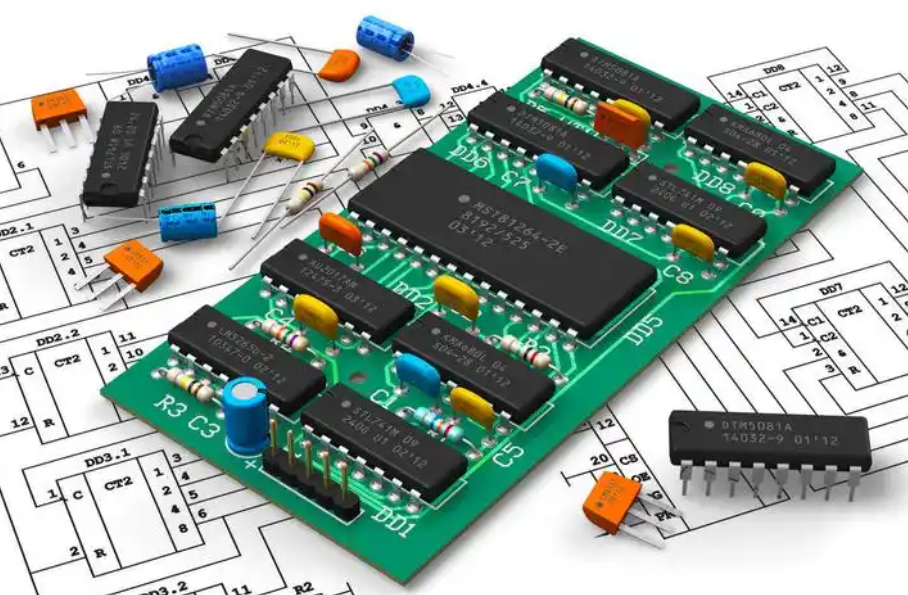

Finally, the type of component itself plays a significant role. Non-moisture-sensitive parts like resistors, capacitors (certain types), and inductors generally have a much longer shelf life—often several years—as their failure modes are less dramatic. In contrast, Moisture-Sensitive Devices (MSDs), complex ICs, electrolytic capacitors (which can dry out), and batteries (which self-discharge) have much stricter and shorter validity periods.

Part 2: Managing and Mitigating Shelf Life Challenges in the Supply Chain

Effective management of component validity is a proactive discipline that spans from procurement to production. A reactive approach—discovering a batch of oxidized or moisture-damaged parts just before a production run—is a recipe for delays and financial loss.

The first line of defense is proper packaging and labeling. Manufacturers ship MSDs in sealed Moisture Barrier Bags (MBBs) along with a humidity indicator card (HIC) and desiccant to control the internal environment. The exterior of the bag must be clearly labeled with critical information: the part number, lot code, MSL rating, peak reflow temperature, and the date code. It is imperative that this packaging remains sealed until the components are ready for use in a controlled environment.

Implementing a First-In-First-Out (FIFO) inventory system is a fundamental best practice. This logistics strategy ensures that the oldest stock (based on date code) is used first, preventing components from languishing in storage beyond their effective life. Modern Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS) can automate this process, tracking date codes and alerting planners when stock is approaching its recommended shelf life.

For components that have exceeded their floor life or whose MBB has been breached, controlled baking is the standard recovery process. As defined in J-STD-033, baking involves heating components in a dedicated oven for a specified duration at a temperature below their maximum tolerance (typically 125°C) to drive out absorbed moisture. The required bake time depends on the component’s thickness and MSL rating. However, it is crucial to note that baking is not a cure-all; it can stress components and may not fully restore solderability if oxidation is severe.

In today’s market, where counterfeit components and extended lead times are common challenges, sourcing from reputable distributors is more important than ever. This is where specialized platforms prove their worth. ICGOODFIND serves as a critical resource for engineers and purchasers, offering a centralized database to verify component authenticity, access detailed datasheets including MSL ratings, and identify alternative or obsolete parts. By providing reliable information on a component’s provenance and lifecycle status, such platforms help mitigate the risk of introducing aged or counterfeit parts into the supply chain inadvertently.

Part 3: Testing and Requalification of Aged Components

When dealing with components that are near or past their official shelf life—a common scenario in repair operations or for legacy systems—simply proceeding with assembly is an unacceptable risk. A rigorous process of testing and requalification must be undertaken to verify fitness for use.

The most common and critical test is solderability testing. This evaluates the ability of the component’s leads to form a reliable solder joint. A standard method involves dipping sample leads into a pot of molten solder and assessing the quality of wetting—whether the solder flows smoothly and evenly coats the surface. Poor wetting indicates significant oxidation and signals that the component should not be used without rework.

Visual inspection under magnification is another essential step. Inspectors look for signs of oxidation (discoloration or dulling of the leads), damage to the package integrity (cracks or scratches), and legibility of markings. Any physical anomalies are red flags.

For more critical applications, electrical testing may be necessary. This involves using specialized equipment to verify that the component still meets its key electrical parameters (e.g., resistance, capacitance, threshold voltages). While this may not be feasible for every single part in a large batch, performing these tests on a representative sample can provide confidence in the entire lot.

In cases where solderability has been compromised but the component is otherwise functional, lead re-finishing may be an option. This process typically involves abrading or chemically cleaning the oxidized layer from the leads and reapplying a fresh solder coating. This is a specialized process that should be performed by qualified technicians, as it can easily damage sensitive components.

The decision to use aged components always involves a risk-versus-reward calculation. The cost of testing and requalification must be weighed against the cost and lead time of procuring new components. For high-reliability applications where failure is not an option, using new parts from an authorized source is almost always the recommended path.

Conclusion

The validity period of electronic components is an indispensable consideration that permeates every stage of the product lifecycle, from design and procurement to assembly and long-term support. It is a multidimensional challenge influenced by material properties, environmental conditions, and rigorous industry standards like the J-STD-033 for moisture sensitivity. Successfully navigating this challenge requires a disciplined approach centered on proper storage practices, strict FIFO inventory management, and a clear understanding of mitigation techniques like controlled baking. Furthermore, when dealing with aged stock, a methodical regimen of testing and requalification is non-negotiable for ensuring end-product quality and reliability. In an increasingly complex global marketplace, leveraging comprehensive information resources such as ICGOODFIND provides a significant strategic advantage, enabling professionals to verify component data proactively and manage their inventories with greater confidence. Ultimately, respecting the shelf life is not just about preserving components; it is about safeguarding reputation, ensuring safety, and achieving operational excellence.