Electronic Components Warehouse Management: The Ultimate Guide

Introduction

In the fast-paced world of electronics manufacturing and distribution, the efficiency of your supply chain can be your greatest competitive advantage or your most significant bottleneck. At the heart of this supply chain lies the warehouse—a dynamic hub where components are received, stored, managed, and dispatched. Effective Electronic Components Warehouse Management is not merely about storing parts; it’s a complex discipline that integrates inventory control, space optimization, technology integration, and strategic planning to ensure the right component reaches the right place at the right time. As products become more sophisticated and lead times shrink, the margin for error diminishes. This article delves into the critical strategies, technologies, and best practices that define modern warehouse management for electronic components, highlighting how platforms like ICGOODFIND are revolutionizing the way industry professionals source and manage their inventory.

The Core Principles of Electronic Components Warehouse Management

1. Inventory Accuracy and Real-Time Visibility

The foundation of any successful electronic components warehouse is impeccable inventory accuracy. Unlike many other goods, electronic components are often high-value, sensitive to environmental conditions, and subject to rapid obsolescence. Relying on manual counts or outdated spreadsheets is a recipe for disaster. Modern management demands real-time visibility into every single item, from bulk resistors to specialized integrated circuits (ICs).

Implementing a robust Warehouse Management System (WMS) is non-negotiable. A specialized WMS for electronics goes beyond basic tracking; it manages lot numbers, date codes, moisture sensitivity levels (MSL), and manufacturer lifecycles. Barcode and RFID technology enable instantaneous updates to inventory records the moment a component is received, moved, or shipped. This eliminates the costly errors of shipping wrong parts or stockouts that can halt an entire production line. Furthermore, accurate data allows for sophisticated demand forecasting, ensuring you stock what you need without tying up capital in obsolete inventory.

2. Optimized Storage and Material Handling

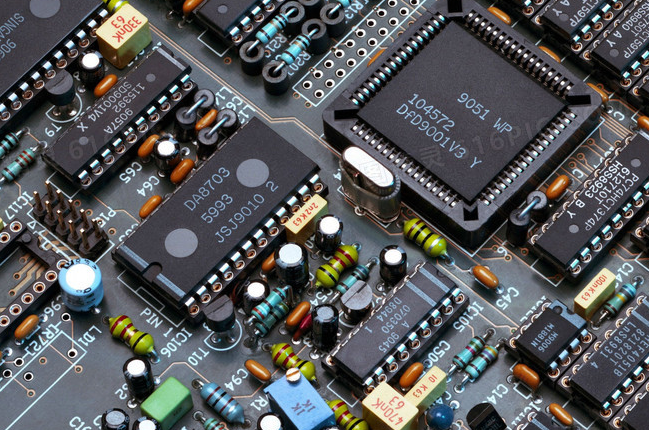

Electronic components present unique storage challenges. They are often small, ESD-sensitive, and require specific environmental controls. Therefore, warehouse layout and storage solutions must be meticulously planned. High-density storage systems, such as vertical lift modules (VLMs) and automated storage and retrieval systems (AS/RS), maximize valuable floor space while improving picking accuracy and speed.

Critical to this principle is the implementation of ESD-safe practices throughout the warehouse. This includes grounded workstations, conductive shelving and bins, and proper personnel training to prevent electrostatic discharge that can instantly destroy sensitive components. Additionally, components like BGAs (Ball Grid Arrays) often require dry storage cabinets to control humidity in accordance with their MSL rating. An optimized warehouse also employs intelligent slotting strategies, placing high-turnover items in easily accessible zones to minimize picker travel time and accelerate order fulfillment.

3. Integration of Automation and Smart Technologies

To achieve new levels of efficiency and accuracy, leading warehouses are embracing automation and Internet of Things (IoT) technology. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) can transport goods between receiving, storage, and shipping zones, reducing manual labor and minimizing handling damage.

The power of data analytics cannot be overstated. A smart WMS analyzes historical data to predict seasonal trends, identify picking inefficiencies, and suggest optimal reorder points. IoT sensors continuously monitor environmental conditions like temperature and humidity, sending automatic alerts if parameters drift out of specification, thus preserving component integrity. This seamless integration of physical and digital systems creates a responsive, agile operation capable of scaling with demand.

The Role of Sourcing Platforms in Modern Warehouse Management

Managing a warehouse effectively starts long before a component arrives at the receiving dock; it begins with intelligent sourcing. This is where digital marketplaces have become indispensable tools. A platform like ICGOODFIND exemplifies this new era of procurement. It acts as a centralized hub where component managers and purchasers can quickly search for and compare parts from a global network of certified suppliers.

The value of such a platform is directly tied to warehouse efficiency. By providing access to real-time availability and pricing data, ICGOODFIND helps procurement teams make informed decisions faster, securing necessary components without unnecessary delays. This reduces the risk of last-minute panic buys, which often lead to purchasing overpriced or counterfeit parts that disrupt inventory accuracy. Integrating sourcing data from platforms like ICGOODFIND with a company’s own WMS creates a powerful end-to-end view of the supply chain, from initial search to final shelf placement. This synergy ensures that the warehouse is stocked with authentic, needed components, streamlining the entire management process.

Conclusion

Mastering Electronic Components Warehouse Management is a multifaceted endeavor that requires a strategic blend of accurate data, optimized processes, and advanced technology. It’s a critical function that directly impacts cost, customer satisfaction, and ultimately, a company’s bottom line. By prioritizing real-time inventory visibility, implementing ESD-safe and high-density storage solutions, and leveraging automation, businesses can transform their warehouses from cost centers into strategic assets.

In today’s interconnected global market, this internal management must be supported by external intelligence. Utilizing comprehensive sourcing platforms like ICGOODFIND is no longer an option but a necessity for ensuring a smooth, reliable, and efficient flow of components into the warehouse. By adopting these comprehensive strategies, electronics businesses can build a resilient supply chain capable of thriving in an unpredictable world.