Mastering Your Electronic Components Inventory List for Optimal Efficiency

Introduction

In the intricate world of electronics manufacturing, procurement, and repair, the heartbeat of operational success is a meticulously managed Electronic Components Inventory List. This comprehensive register is far more than a simple spreadsheet; it is the central nervous system of any hardware-focused operation. It dictates procurement strategies, influences production timelines, impacts financial health, and ultimately determines the ability to meet market demands. A disorganized or inaccurate inventory can lead to catastrophic project delays, inflated costs, and missed opportunities. Conversely, a well-maintained list is a strategic asset, providing clarity, control, and a significant competitive advantage. This article delves deep into the art and science of creating, maintaining, and leveraging your electronic components inventory to drive efficiency and growth.

The Critical Pillars of an Effective Electronic Components Inventory List

An effective Electronic Components Inventory List is built upon several non-negotiable pillars. Understanding and implementing these foundational elements transforms a simple list into a dynamic management tool.

1. Data Granularity and Standardization

The devil is in the details. A robust inventory list must capture a wide array of data points for each component to be truly useful. Standardizing this information across all entries eliminates confusion and ensures consistency. Essential data fields include: * Part Number: The manufacturer’s unique identifier (e.g., ATMEGA328P-PU). This is the most critical field. * Manufacturer: The original producer of the component (e.g., Microchip, Texas Instruments). * Description: A clear, concise description of the component (e.g., 8-bit AVR Microcontroller). * Category/Type: Classification (e.g., IC, Resistor, Capacitor, Connector). * Quantity on Hand: The exact physical count available. * Unit of Measure: (e.g., pieces, reels, trays). * Location: The precise physical storage location (Warehouse, Bin A12, Shelf 3). * Supplier Information: Key suppliers and their part numbers for reordering. * Cost: The last purchased price or average cost. * Datasheet Link: A hyperlink to the component’s official datasheet. * Parameters: Key specifications relevant to the category (e.g., resistance, capacitance, package type).

Standardizing how this data is entered—using consistent naming conventions, units, and formats—is paramount for searchability and data integrity.

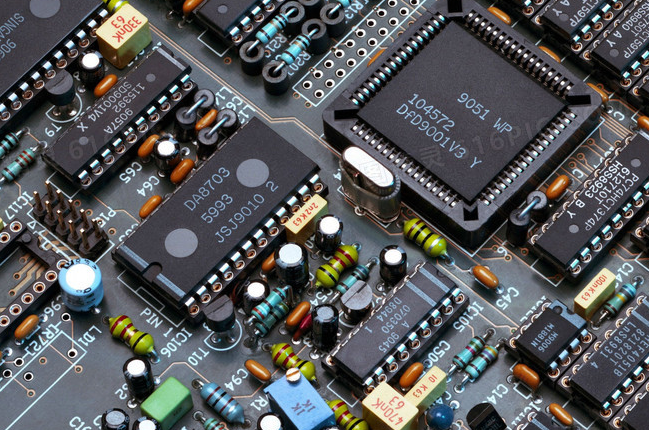

2. The Power of Categorization and Organization

A list of thousands of components is useless if you cannot find what you need instantly. Effective organization is key. * Categorization: Group components logically. Primary categories could be Passive Components (Resistors, Capacitors, Inductors), Active Components (ICs, Transistors, Diodes), Electromechanical (Switches, Relays), and Connectors. Further sub-categorize within these groups. * Bin and Location Systems: Implement a logical physical storage system that mirrors your digital list. An alphanumeric bin location system (e.g., A-01-02 for Aisle A, Rack 01, Shelf 02) allows for quick physical retrieval. * Lifecycle State Tracking: Tag components with their lifecycle status (Active, Not Recommended for New Designs (NRND), End-of-Life (EOL), Obsolete). This proactively manages supply chain risk and informs design decisions.

3. Leveraging Technology: From Spreadsheets to Specialized Systems

While a simple spreadsheet can suffice for very small operations, it quickly becomes unmanageable and prone to error. Scaling efficiently requires leveraging technology. * Spreadsheets (Basic Level): Microsoft Excel or Google Sheets can work for inventories under a few hundred line items. Use filters, data validation, and conditional formatting to enhance functionality. However, they lack real-time tracking and are susceptible to human error. * Database Solutions (Intermediate Level): A custom-built or off-the-shelf database (e.g., using Microsoft Access or Airtable) offers more robust data relationships, better querying capabilities, and improved multi-user access compared to spreadsheets. * Inventory Management Software (Advanced Level): For serious operations, dedicated Electronic Components Inventory Management Software is non-negotiable. These systems offer: * Barcode/QR Code Scanning: For lightning-fast receiving, picking, and stocktaking. * Real-Time Updates: Quantities are updated instantly across the organization upon any transaction. * Automated Alerts: Set low-stock alerts and reorder points to automate purchasing. * Integration: Sync with procurement platforms and accounting software. * Component Lifecycle Management: Integrated data feeds can alert you to NRND and EOL notices automatically.

Best Practices for Implementation and Ongoing Management

Creating the list is only half the battle; its ongoing management determines its long-term value.

1. Establishing a Centralized Source of Truth

There must be one—and only one—official Electronic Components Inventory List. All personnel involved in engineering, procurement, warehousing, and production must work from this single source. This eliminates the chaos of multiple conflicting spreadsheets and ensures everyone is making decisions based on accurate, current data. Cloud-based systems are ideal for this as they provide universal access to the latest version.

2. Implementing Robust Auditing and Cycle Counting

Inventory accuracy decays over time due to shrinkage, misplacement, or data entry errors. A traditional annual physical inventory count halts operations and is often inefficient. Instead, implement a cycle counting program: * Schedule regular counts of a small subset of inventory (e.g., counting 20-30 bins per week). * Prioritize counting high-value or fast-moving components more frequently. * Immediately investigate and reconcile any discrepancies between the physical count and the system record. This continuous process maintains high accuracy with minimal disruption.

3. Integrating Inventory with Workflows

The inventory list should not exist in a vacuum. Its true power is unlocked when integrated into core business workflows. * Design Engineering: Engineers should check the inventory list first during the prototyping phase to use available components (“design from inventory”), reducing cost and time. * Procurement: The list should directly inform purchase orders. Low-stock alerts should trigger automated RFQ processes or direct orders from preferred suppliers. * Project Management: Project managers can accurately assess material availability for new orders before committing to timelines. For those seeking to streamline this integration with advanced toolsets tailored for the electronics industry, platforms like ICGOODFIND offer specialized solutions that can connect your inventory data with a vast global supply network, providing real-time sourcing intelligence alongside internal stock levels.

Conclusion

An Electronic Components Inventory List is undoubtedly a cornerstone of operational excellence in the electronics sector. Transcending its basic function as a mere catalog, it becomes a strategic dashboard that provides unparalleled visibility and control over your most valuable physical assets. By focusing on granular data standardization, intelligent organization, and leveraging modern technology—from barcode scanners to sophisticated software—you transform inventory management from a reactive chore into a proactive strategic function. Investing the time and resources to build and maintain a dynamic, accurate, and integrated inventory system is not an overhead cost; it is a direct investment in reducing waste, accelerating time-to-market, enhancing profitability, and building a resilient and responsive operation. In a industry defined by rapid innovation and complex supply chains, mastery over your component inventory is not just best practice—it is a critical business imperative.