MCU Power Supply Circuit: The Unsung Hero of Reliable Embedded Systems

Introduction

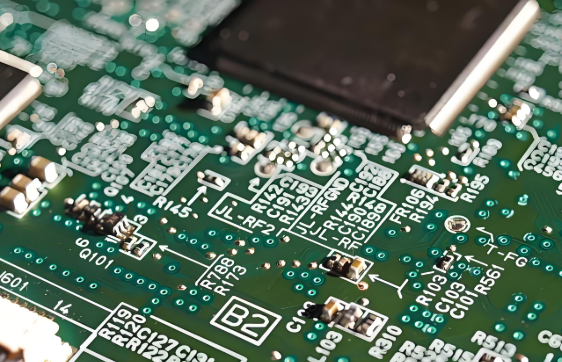

In the intricate world of embedded electronics, the spotlight often shines on the Microcontroller Unit (MCU) itself—its processing speed, architecture, and peripheral features. However, the silent guardian ensuring its very existence and stable operation is frequently overlooked: the MCU Power Supply Circuit. This critical subsystem is far more than just a voltage converter; it is the foundational bedrock upon which system reliability, performance, and longevity are built. A poorly designed power supply can lead to a cascade of failures, from erratic behavior and data corruption to permanent hardware damage. This article delves deep into the essential components, design considerations, and best practices for creating robust MCU power supply circuits, highlighting why meticulous attention to this area is non-negotiable for any successful product. For engineers seeking reliable components to bring these designs to life, platforms like ICGOODFIND offer a streamlined path to sourcing verified power management ICs and supporting components.

Main Body

Part 1: Core Components and Topology of an MCU Power Rail

An MCU’s power requirement is not monolithic. Modern MCUs often require multiple voltage rails: a core voltage (e.g., 1.2V, 3.3V) for internal logic, an I/O voltage (e.g., 3.3V, 5V) for communicating with external devices, and sometimes an analog voltage for sensitive ADCs/DACs. The power supply circuit must cater to these needs with precision and isolation.

The primary components include: * Voltage Regulator: The heart of the circuit. The choice between a Low-Dropout Regulator (LDO) and a Switching Regulator (Buck, Boost) is fundamental. * LDOs provide superior noise performance and simplicity, making them ideal for noise-sensitive analog rails or as post-regulators after a switching stage. Their key drawback is efficiency, as they dissipate excess voltage as heat. * Switching Regulators (SMPS) are highly efficient (often >90%) and can step-up (boost), step-down (buck), or invert voltages. They are essential for battery-powered applications or when significant voltage differences exist. However, they introduce switching noise that must be carefully managed through layout and filtering. * Passive Components: These are not mere supporting actors. High-quality, low-ESR capacitors are crucial for stability, transient response, and noise filtering. Ceramic capacitors placed close to the MCU pins decouple high-frequency noise, while bulk tantalum or electrolytic capacitors handle lower-frequency transients. Inductors in switching circuits store and transfer energy; their saturation current and DC resistance directly impact performance. * Protection Circuits: A robust design anticipates faults. Transient Voltage Suppression (TVS) diodes clamp voltage spikes from electrostatic discharge (ESD) or inductive load switching. Polymer fuses or resettable PPTCs protect against overcurrent conditions. Input reverse-polarity protection using a series diode or MOSFET is also a common safeguard.

Part 2: Critical Design Considerations for Stability and Efficiency

Moving beyond component selection, the actual performance hinges on detailed design decisions.

- Voltage Accuracy and Ripple: The MCU’s specified operating voltage range is absolute. Excessive ripple or an out-of-spec voltage can cause internal logic errors, ADC inaccuracies, or even latch-up. Design must account for load transients—when the MCU suddenly switches on a peripheral—ensuring the regulator responds quickly to prevent sagging below the minimum voltage. This involves careful feedback loop compensation and proper output capacitor selection.

- Power Sequencing: In multi-rail systems, the order in which voltages are applied and removed can be critical. Some MCUs require the core voltage to be established before or simultaneously with the I/O voltage to prevent internal parasitic currents. This often necessitates regulators with enable pins controlled by simple RC delays or by a dedicated power management IC.

- Thermal Management: Heat is the enemy of electronic reliability. The power supply is often the primary heat source. The power dissipated in a linear regulator is (V_in - V_out) * I_load. For high currents or large voltage differences, this mandates a heatsink or a forced switch to an SMPS topology. Proper PCB layout with adequate copper pours for heat sinking is essential.

- Electromagnetic Compatibility (EMC): The power supply circuit can be both a victim and a source of electromagnetic interference. Switching regulators generate high-frequency noise that can radiate or conduct back into the input line or into the MCU itself. Strategies include:

- Using a pi-filter (C-L-C) at the input of switching regulators.

- Implementing a star-grounding topology to avoid noisy return currents flowing under sensitive analog sections.

- Keeping high-current switching loops as small as physically possible.

- Shielding inductors in noise-critical applications.

Part 3: Layout Best Practices: Where Theory Meets Reality

A perfect schematic can be ruined by a poor PCB layout, especially for power supplies. Adhering to layout rules is paramount.

- Minimize High-Current Paths: The main current paths from the input source, through the switch (in an SMPS), through the inductor, to the output capacitor, and back to ground should be kept extremely short and wide. This reduces parasitic inductance that causes voltage spikes and reduces radiated noise.

- Component Placement: Place the regulator IC, its associated input capacitor, output capacitor, and inductor (if any) as close together as possible. The critical bypass/decoupling capacitors for the MCU must be placed as close as physically feasible to its power pins, with vias directly connecting to the ground plane.

- Ground Plane Integrity: A solid, low-impedance ground plane is the most important noise mitigation tool. Avoid splitting the ground plane under the analog power section; instead, use a single continuous plane and carefully place components to separate current flows logically.

- Feedback Trace Sensitivity: The trace connecting the output voltage divider to the regulator’s feedback pin is highly sensitive. It should be kept away from all sources of noise like switching nodes and inductor magnetic fields. Often, it is recommended to route this trace as a dedicated “microstrip” back to the IC.

Navigating these complex design and sourcing challenges is where a specialized component platform proves invaluable. Engineers can leverage resources like ICGOODFIND to efficiently compare specifications, access datasheets, and procure genuine power management ICs and precision passive components that meet the stringent demands of modern MCU power systems.

Conclusion

The MCU power supply circuit is a masterpiece of pragmatic engineering that balances efficiency, stability, cost, and size. It demands respect and deep understanding from the designer. Neglecting its intricacies risks dooming an otherwise brilliant embedded system design to field failures and unreliable operation. By mastering the interplay between topology selection, component characteristics, protection mechanisms, and—most critically—PCB layout practices, engineers can transform this “unsung hero” into a pillar of robustness. In an era where devices are expected to operate flawlessly in increasingly challenging environments, investing time in perfecting the power supply is not just good practice—it is essential engineering discipline. Ultimately, a reliable product starts with clean, stable power.