MCU Power Supply: The Unsung Hero of Reliable Embedded Systems

Introduction

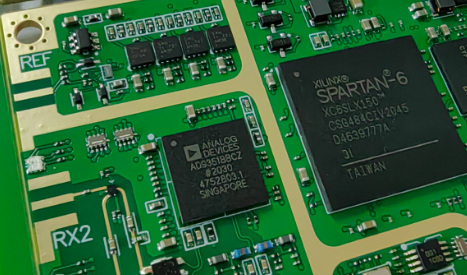

In the intricate world of embedded electronics, the spotlight often shines on the Microcontroller Unit (MCU) itself—its processing speed, architecture, and peripheral features. However, the consistent and reliable operation of any MCU is fundamentally dependent on a component that operates behind the scenes: the MCU Power Supply. This critical subsystem is far more than just a voltage converter; it is the foundational pillar that determines system stability, performance, and longevity. A poorly designed power supply can lead to erratic behavior, data corruption, premature failure, and increased electromagnetic interference (EMI), undermining even the most sophisticated MCU’s capabilities. This article delves into the core principles, design challenges, and best practices for creating robust MCU power solutions, ensuring your embedded design operates flawlessly from prototype to production. For engineers seeking to navigate the complexities of component selection and circuit optimization, platforms like ICGOODFIND provide invaluable resources for comparing power management ICs and sourcing reliable components.

The Core Principles of MCU Power Delivery

Understanding the fundamental requirements of an MCU is the first step in designing an appropriate power supply. Modern MCUs are not monolithic in their power needs; they often require multiple, precisely regulated voltage rails.

First and foremost is voltage regulation and accuracy. Most modern MCUs operate at core voltages as low as 1.8V, 3.3V, or 5V, with stringent tolerance requirements, often within ±5% or tighter. Exceeding these limits can cause permanent damage or latch-up. The power supply must maintain this regulation under varying conditions of input voltage and load current. Linear regulators offer simple, low-noise solutions for smaller voltage differentials, while switching regulators (SMPS) provide high efficiency for applications with wider input ranges or higher power demands, albeit with more complex noise management.

Secondly, managing dynamic current demands is crucial. An MCU’s current consumption is not constant. It experiences rapid spikes during events like CPU wake-up, peripheral activation (e.g., radio transmission), or flash memory writes. These transient load steps demand a power supply with excellent transient response. The output capacitors’ Equivalent Series Resistance (ESR) and Inductance (ESL), along with the regulator’s control loop bandwidth, must be carefully designed to prevent significant voltage droops or overshoots that could trigger brown-out resets or logic errors.

Finally, power sequencing and multi-rail management have become increasingly important. Systems with separate core voltage (Vcore) and I/O voltage (Vddio) rails may require a specific sequence—such as bringing up I/O before core or vice-versa—to prevent internal parasitic currents and ensure proper initialization. Furthermore, low-power modes (Sleep, Stop, Standby) are essential for battery-operated devices. The power supply must itself be efficient at light loads and may need to provide “always-on” rails while others are switched off, necessitating thoughtful use of load switches and low-quiescent-current LDOs.

Navigating Key Design Challenges and Noise Mitigation

Designing an MCU power supply is replete with challenges that extend beyond basic voltage conversion. Overcoming these hurdles is what separates a functional prototype from a robust, market-ready product.

A primary challenge is mitigating power supply noise. Noise can couple into sensitive analog peripherals (ADCs, DACs), cause clock jitter, and lead to electromagnetic compatibility (EMC) failures. Switching regulators are major noise generators, creating both conducted noise (through input and output lines) and radiated noise (from the switching node). Effective strategies include: implementing a proper PCB layout with short, wide traces for high-current paths; using a solid ground plane; placing input capacitors close to the regulator IC; and shielding sensitive traces. Additionally, the strategic use of ferrite beads and pi-filters (LC filters) can isolate noisy switching supplies from clean analog rails powered by subsequent LDOs.

Thermal management is another critical consideration. The efficiency of the power converter directly impacts its heat dissipation. A linear regulator dissipates power as (Vin - Vout) * Iload, which can become substantial at higher currents or voltage drops. This not only wastes battery life but may require heatsinks or forced airflow. Switching regulators are more efficient but still generate heat due to switching losses and conduction losses in the inductor and MOSFETs. Proper thermal design involves calculating power dissipation, ensuring adequate copper pour for heat sinking on the PCB, and selecting components with appropriate thermal ratings to maintain reliability over the intended operating temperature range.

Furthermore, ensuring robustness against real-world disturbances is non-negotiable. The power supply must handle input voltage transients (load dumps in automotive, plug insertion), electrostatic discharge (ESD), and short-circuit events. Incorporating protection elements such as transient voltage suppressors (TVS diodes), input polarity protection, and regulators with built-in over-current and thermal shutdown features is essential. For battery-powered applications, under-voltage lockout (UVLO) functionality gracefully shuts down the system before the battery is deeply discharged, protecting it from damage.

Best Practices for Optimization and Future Trends

Optimizing an MCU power supply involves a holistic approach that balances performance, cost, size, and reliability throughout the product lifecycle.

Component selection forms the bedrock of a good design. Choosing the right regulator IC involves evaluating parameters beyond basic voltage and current: quiescent current (for battery life), efficiency curves across load ranges, switching frequency (higher frequencies allow smaller inductors but increase losses), and feature sets like power-good flags and enable pins. Inductor selection is equally critical; parameters like saturation current (Isat) and DC resistance (DCR) must be rated for the application’s peak current to avoid efficiency loss or failure. Similarly, using capacitors with low ESR, such as ceramic capacitors, is vital for stabilizing the output voltage and handling transients.

Rigorous validation through testing cannot be overstated. Design verification should include: * Measuring ripple and noise on all rails with an oscilloscope. * Stress-testing with dynamic load profiles to check transient response. * Testing across the full temperature range. * Conducting EMC pre-compliance tests for radiated and conducted emissions. A platform like ICGOODFIND can be instrumental in this phase by helping engineers find alternative components with better performance or availability if initial choices fall short during testing.

Looking ahead, trends are pushing power supply design toward greater integration and intelligence. Power Management ICs (PMICs) are becoming ubiquitous, integrating multiple LDOs, switching converters, sequencers, and fuel gauges into a single chip, simplifying design for complex systems-on-chip (SoCs). Furthermore, the rise of energy harvesting for IoT devices demands ultra-low-power supply circuits that can start up from minimal energy and manage irregular power inputs. These advancements underscore the evolving sophistication of the humble MCU power supply.

Conclusion

The MCU power supply is unequivocally the unsung hero of embedded system design. Its role transcends simple conversion; it is an active guardian of system integrity, performance consistency, and operational efficiency. From ensuring precise voltage regulation under dynamic loads to battling electromagnetic noise and managing thermal constraints, a well-engineered power architecture is paramount. By adhering to core principles—meticulous component selection intelligent PCB layout comprehensive protection strategies—and leveraging resources available through specialized platforms engineers can transform this critical challenge into a competitive advantage As MCUs continue to evolve towards lower voltages higher integration greater complexity the innovation surrounding their power delivery will remain at the forefront of enabling next-generation electronic devices.