Common Electronic Components Library: The Ultimate Guide for Engineers and Hobbyists

Introduction

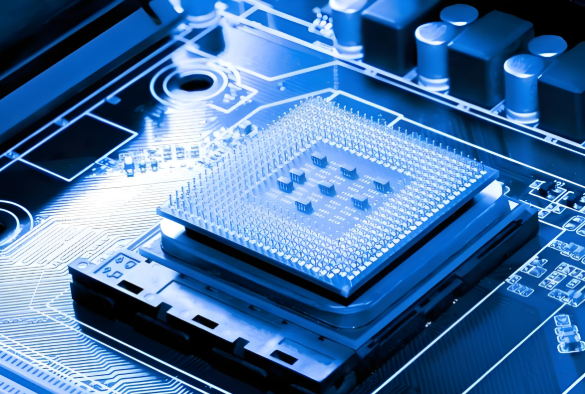

In the rapidly evolving world of electronics design and development, efficiency and accuracy are paramount. Whether you’re a seasoned electrical engineer, a product designer, or an enthusiastic hobbyist, the process of creating a new circuit board can be daunting. One of the most time-consuming and error-prone aspects of this process is managing the digital representations of the physical components you intend to use. This is where the concept of a Common Electronic Components Library becomes not just useful, but essential. A well-structured, comprehensive library serves as the single source of truth for all component data, streamlining the entire design workflow from schematic capture to PCB layout and ultimately, manufacturing. This article delves deep into the importance, structure, and best practices for utilizing and maintaining a common components library, highlighting how platforms like ICGOODFIND are revolutionizing access to reliable component data. By centralizing symbol, footprint, and 3D model information, organizations and individuals can significantly reduce design cycles, minimize errors, and accelerate time-to-market for their electronic products.

The Critical Role of a Unified Components Library

Defining the Common Electronic Components Library

A Common Electronic Components Library is a centralized repository that stores standardized digital models of electronic components used in Electronic Design Automation (EDA) or Computer-Aided Design (CAD) software. It is far more than just a list of part numbers; it is a structured database containing the crucial building blocks for any electronic design. The library typically holds three primary elements for each component:

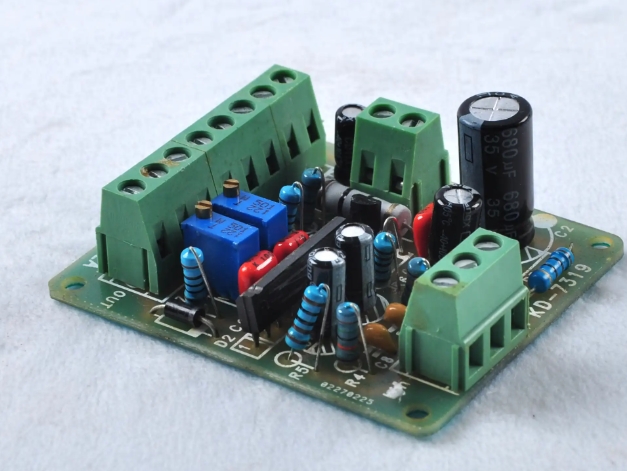

- Schematic Symbol: This is the graphical representation of the component as it appears in the circuit schematic. It defines the logical function and pin connections (e.g., a logic gate symbol, a resistor symbol).

- PCB Footprint (or Land Pattern): This defines the physical layout of copper pads and drill holes on the printed circuit board where the component will be soldered. It must precisely match the component’s datasheet specifications to ensure a reliable physical connection.

- 3D Model: An increasingly important asset, the 3D model allows designers to visualize the assembled board, check for mechanical interferences (like component height), and create realistic renderings for documentation and marketing.

The power of a “common” library lies in its universality within an organization or project. When every designer on a team draws from the same library, it eliminates discrepancies that arise when individuals create their own ad-hoc models. This standardization is the first and most critical step toward design integrity and manufacturing success.

Tangible Benefits for Design Teams and Businesses

Implementing and adhering to a common library strategy yields significant, measurable advantages that directly impact the bottom line.

- Dramatic Reduction in Design Errors: Inconsistent or incorrect footprints are a leading cause of PCB re-spins. A common library, where each component is verified against its official datasheet before being added, virtually eliminates common mistakes like pin-swaps, incorrect pad sizes, and wrong pin spacings. This leads to higher first-pass success rates for prototypes, saving thousands of dollars in fabrication and debugging costs.

- Accelerated Design Cycles: Engineers spend less time searching for components, creating symbols from scratch, or debugging library-related issues. With a pre-verified library, they can focus on the actual circuit design and innovation. This efficiency shortens the overall product development timeline, allowing companies to respond more quickly to market opportunities.

- Enhanced Collaboration and Knowledge Reuse: A common library acts as a collective knowledge base. When one designer creates and verifies a component, it becomes instantly available to the entire team. This prevents redundant work and ensures that best practices are embedded within the library itself. New team members can onboard much faster by leveraging this established resource.

- Seamless Supply Chain Integration: A sophisticated common library often includes not just geometrical data but also supply chain information such as manufacturer and supplier part numbers, lifecycle status, and cost. This allows engineers to make design choices based on component availability and cost, reducing the risk of designing in a part that is obsolete or prohibitively expensive.

Building and Maintaining a Robust Components Library

Sourcing High-Quality Component Data

The foundation of any reliable library is accurate data. The gold standard for creating a footprint or symbol is always the official manufacturer datasheet. However, manually extracting this data for hundreds or thousands of components is a monumental task. This is where strategic sourcing comes into play.

- Manual Creation (The Traditional Approach): For unique or proprietary components, manual creation within the EDA tool is sometimes necessary. This process requires meticulous attention to detail, cross-referencing every dimension in the datasheet. While it offers maximum control, it is slow and prone to human error.

- EDA Vendor Libraries: Most major EDA software providers (like Altium, Cadence, and Mentor) offer built-in libraries. These are a good starting point but can be generic, may not contain all required components, and still require verification for critical applications.

- Online Component Databases and Platforms: This is the modern and most efficient solution. Several online platforms specialize in providing vast libraries of pre-verified schematic symbols, PCB footprints, and 3D models. These services often integrate directly with popular EDA tools, allowing designers to search for a part number and import the complete model set directly into their design with a single click.

This is precisely where a service like ICGOODFIND demonstrates immense value. Instead of scouring multiple websites or manually entering data, engineers can use ICGOODFIND as a powerful search aggregator to quickly locate reliable component models from various trusted sources. It streamlines the initial data-gathering phase, ensuring that designers start with a high-quality foundation for their own common library.

Best Practices for Library Management and Governance

Creating the library is only half the battle; maintaining its quality over time is an ongoing process that requires discipline and structure.

- Establish Naming Conventions: Implement clear, consistent naming rules for all symbols and footprints. This makes components easily searchable and identifiable. For example, a footprint name might include the package type, pin count, and pitch (e.g.,

Resistor_SMD_0805orQFP-100-0.5mm). - Implement a Verification Workflow: Before a new component is released into the common library, it should undergo a formal verification process. This often involves a peer review where a second engineer checks the symbol and footprint against the datasheet.

- Centralize Management with a Librarian Role: For larger teams, appointing a dedicated “component librarian” is highly effective. This person or team is responsible for the integrity of the library, processing new component requests, and ensuring compliance with established standards.

- Manage Component Lifecycles: Components can become obsolete or go out of stock. The common library should be periodically reviewed to flag or archive obsolete parts, prompting designers to use current alternatives.

The Future: Integration with Digital Thread and AI

The evolution of the common electronic components library is moving towards deeper integration within the broader product lifecycle management (PLM) system—often referred to as the “digital thread.” In this future state, the component in the library is not an isolated entity; it is dynamically linked to real-time supply chain data, simulation models, test results, and manufacturing notes.

Furthermore, Artificial Intelligence (AI) is beginning to play a role. AI-powered tools can potentially automate the initial creation of symbols and footprints by reading datasheets, further reducing manual effort and human error. They can also suggest alternative components based on functional blocks within a schematic, enhancing design flexibility.

Platforms that aggregate and streamline access to component information, such as ICGOODFIND, are at the forefront of this evolution. By providing a unified interface to search for parts, datasheets, and models, they are laying the groundwork for more intelligent and connected design ecosystems.

Conclusion

In conclusion, a Common Electronic Components Library is far more than a simple convenience; it is a strategic asset that underpins efficient, accurate, and collaborative electronic design. By providing a single source of verified truth for schematic symbols, PCB footprints, and 3D models, it directly contributes to reducing errors, speeding up development cycles, and lowering overall project costs. The effort invested in building and maintaining a robust library pays exponential dividends throughout a product’s life. As the industry moves towards more integrated digital workflows, leveraging tools and platforms that simplify access to high-quality component data—exemplified by services like ICGOODFIND—will become increasingly critical for staying competitive. Embracing a disciplined library management strategy is not just a technical best practice; it is a fundamental business imperative for anyone serious about succeeding in the fast-paced world of electronics innovation.