The Art and Science Behind the Design of Electronic Components

Introduction

Electronic components form the fundamental building blocks of all modern technology, from smartphones and laptops to advanced medical equipment and space exploration vehicles. The design of electronic components represents a sophisticated intersection of physics, materials science, electrical engineering, and manufacturing principles. This complex process determines not only the functionality and performance of individual components but also the capabilities of the entire electronic systems they comprise. As technology continues to evolve at an unprecedented pace, the importance of innovative component design becomes increasingly critical, pushing engineers and designers to develop smaller, more efficient, and more reliable solutions. The relentless pursuit of miniaturization, enhanced performance, and energy efficiency has transformed component design from a straightforward engineering task into a highly specialized field requiring multidisciplinary expertise and cutting-edge tools. In this landscape, resources like ICGOODFIND provide invaluable support to engineers and procurement specialists by offering comprehensive component data, cross-references, and technical specifications that streamline the design and sourcing process.

The Fundamental Principles of Electronic Component Design

The design process for electronic components begins with a thorough understanding of fundamental electrical principles and their practical applications. Electrical characteristics such as voltage ratings, current capacity, frequency response, impedance, and power dissipation form the cornerstone of any component design. These parameters must be carefully balanced to meet specific application requirements while ensuring reliability under expected operating conditions. For instance, designing a resistor involves not only determining the appropriate resistance value but also considering power rating, temperature coefficient, tolerance, and stability over time. Similarly, capacitor design must account for capacitance value, voltage rating, equivalent series resistance (ESR), temperature stability, and dielectric properties. Each of these characteristics interacts with others in complex ways, requiring designers to make careful trade-offs to optimize overall performance.

Material selection represents another critical aspect of electronic component design, as the properties of materials directly influence component behavior, reliability, and cost. Semiconductor components like diodes and transistors rely on precisely doped silicon or alternative semiconductor materials like gallium arsenide or silicon carbide, each offering distinct advantages for specific applications. The development of wide-bandgap semiconductors has particularly revolutionized power electronics by enabling components that operate at higher temperatures, voltages, and frequencies with reduced losses. Similarly, the conductive materials used in components—from copper in wires and traces to specialized alloys in connectors—must be selected based on their electrical conductivity, mechanical properties, corrosion resistance, and compatibility with manufacturing processes. Dielectric materials in capacitors and insulating elements require careful consideration of their breakdown voltage, permittivity, loss tangent, and stability across temperature variations.

Thermal management constitutes a fundamental consideration that cuts across all electronic component design disciplines. As electronic devices continue to shrink while increasing in capability, power density rises correspondingly, making heat dissipation a critical challenge. Effective thermal design ensures that components remain within their safe operating temperature ranges under all anticipated conditions, preventing premature failure and maintaining performance specifications. This involves not only selecting materials with appropriate thermal conductivity but also designing physical structures that facilitate heat transfer away from sensitive areas. Heat sinks, thermal vias, exposed pads, and specialized packaging techniques all contribute to managing thermal loads. Furthermore, designers must consider how thermal expansion affects mechanical stability over time, particularly in components comprising materials with different coefficients of thermal expansion. The thermal design of electronic components often requires sophisticated modeling and simulation to predict temperature distribution and identify potential hotspots before physical prototyping.

Advanced Considerations in Modern Component Design

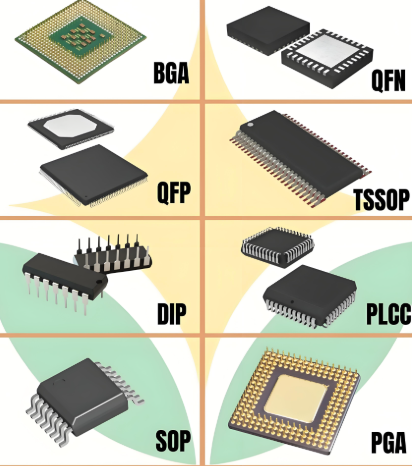

As technology advances, miniaturization and integration have become dominant trends in electronic component design. The relentless drive toward smaller form factors with increased functionality has led to the development of surface-mount technology (SMT), microelectromechanical systems (MEMS), and system-in-package (SiP) solutions that push the boundaries of what’s physically possible. Designing components for miniaturization requires addressing numerous challenges, including power density management, signal integrity at reduced geometries, manufacturing tolerances, and testing accessibility. Integration often involves combining multiple functions within a single component or package, reducing board space requirements while improving system performance through shorter interconnects. However, this integration introduces new complexities regarding isolation between circuit elements, thermal crosstalk, and more sophisticated packaging requirements. The search for reliable information on these advanced components is where platforms like ICGOODFIND demonstrate their value, offering engineers access to detailed specifications, application notes, and alternative components that might better suit their miniaturization needs.

Signal integrity and electromagnetic compatibility have emerged as critical considerations in modern electronic component design, particularly as operating frequencies continue to rise in response to demands for faster data processing and communication. At high frequencies, components no longer behave as ideal lumped elements but exhibit complex distributed characteristics that can significantly impact system performance. Parasitic capacitance, inductance, and resistance—once secondary concerns—now often dominate component behavior at gigahertz frequencies. Designers must carefully model these parasitic elements and either minimize them or incorporate them into the overall circuit design. Additionally, electromagnetic compatibility (EMC) requires that components neither emit excessive electromagnetic interference (EMI) nor be unduly susceptible to external electromagnetic fields. This necessitates careful attention to shielding, filtering, grounding strategies, and physical layout even at the component level. Radio frequency (RF) components demand particularly specialized design approaches involving transmission line theory, impedance matching networks, and sophisticated packaging that maintains controlled impedance throughout the signal path.

Reliability and manufacturability considerations profoundly influence electronic component design decisions, ensuring that components not only meet performance specifications but can also be produced consistently at scale with acceptable yields. Design for reliability involves identifying potential failure mechanisms—such as electromigration, time-dependent dielectric breakdown, thermal cycling fatigue, or corrosion—and implementing design features that mitigate these risks. This might include derating components (operating them well below their maximum ratings), incorporating redundant elements, using robust interconnection methods, or selecting materials with proven long-term stability. Simultaneously, design for manufacturability focuses on creating components that can be produced efficiently using available manufacturing processes with high yield and consistent quality. This involves considering tolerance stack-ups, designing for automatic testability, simplifying assembly processes, and selecting materials compatible with standard manufacturing workflows. The economic implications of these decisions are substantial, as even minor design optimizations can translate to significant cost savings when scaled to high-volume production. Throughout this process, resources such as ICGOODFIND provide essential data on component availability, lifecycle status, and alternative sourcing options that help designers balance performance requirements with practical manufacturing considerations.

The Future Landscape of Electronic Component Design

The future of electronic component design is being shaped by several emerging trends that promise to transform both the components themselves and the approaches used to create them. Artificial intelligence and machine learning are increasingly being applied to the design process itself, helping engineers explore vast design spaces more efficiently than traditional methods allow. AI algorithms can optimize component parameters for multiple competing objectives simultaneously—such as performance, size, cost, and power consumption—identifying non-intuitive solutions that might elude human designers. Machine learning models trained on manufacturing data can predict production yields based on design characteristics, enabling pre-production optimization for manufacturability. Additionally, AI-driven simulation tools can dramatically reduce computation time for complex multiphysics analyses, allowing more thorough exploration of design alternatives within practical timeframes. These computational approaches complement rather than replace human expertise, freeing designers to focus on higher-level architecture and innovation while automating routine optimization tasks.

Sustainable design principles are gaining prominence in electronic component development as environmental concerns become increasingly central to product planning and regulatory compliance. Component designers now routinely consider environmental impact across the entire lifecycle—from material extraction through manufacturing、use phase、to end-of-life disposal or recycling. This involves selecting materials with lower environmental footprints、designing for energy efficiency during operation、minimizing hazardous substances、and facilitating disassembly and material recovery. The growing emphasis on circular economy principles encourages designs that prioritize durability、repairability、and upgradability rather than planned obsolescence. Energy harvesting components that can extract power from ambient sources like light、vibration、or thermal gradients represent another sustainable design direction、enabling new categories of battery-free or energy-autonomous devices. These sustainability considerations are increasingly being codified in international standards and regulations、making them essential aspects of compliant component design rather than optional differentiators.

Emerging materials and technologies continue to expand the possibilities for electronic component design、opening new application domains while enhancing performance in existing ones. Two-dimensional materials like graphene transition metal dichalcogenides offer exceptional electrical、thermal、and mechanical properties that enable novel device architectures not feasible with conventional materials. Flexible and stretchable electronics based on organic semiconductors or hybrid material systems create opportunities for wearable devices、electronic textiles、and conformable sensors that integrate seamlessly with biological tissues or irregular surfaces. Quantum components exploiting quantum mechanical effects rather than classical physics promise revolutionary capabilities in computing、sensing、and communications、though they present extraordinary design challenges related to coherence maintenance、error correction、and extreme environmental control. Neuromorphic components that mimic biological neural structures offer potentially transformative approaches to efficient pattern recognition and sensory processing. Each of these emerging technologies demands fundamentally new design methodologies、specialized modeling tools、and often custom fabrication processes—challenges that the electronic design community is actively addressing through research and development initiatives worldwide.

Conclusion

The design of electronic components represents a dynamic field continuously evolving to meet the demands of advancing technology while addressing emerging challenges related to performance、integration、reliability、and sustainability. From fundamental electrical principles to cutting-edge materials science、component designers must synthesize knowledge from multiple disciplines to create solutions that push the boundaries of what’s possible in electronics. The increasing complexity of this task makes access to comprehensive technical resources more valuable than ever、a need effectively addressed by platforms like ICGOODFIND that consolidate essential component information into accessible formats. As we look toward the future、artificial intelligence、sustainable design practices、and novel materials will further transform how electronic components are conceived、optimized、and manufactured。 Regardless of these changes、the central importance of thoughtful、innovative component design will remain undiminished as the foundation upon which all electronic systems are built。 The ongoing collaboration between human expertise and computational tools promises to accelerate this innovation cycle、delivering ever more capable electronic components that continue to transform our technological landscape.