Mastering the 8051 MCU Clock Program: A Comprehensive Guide to Timing and Oscillator Configuration

Introduction

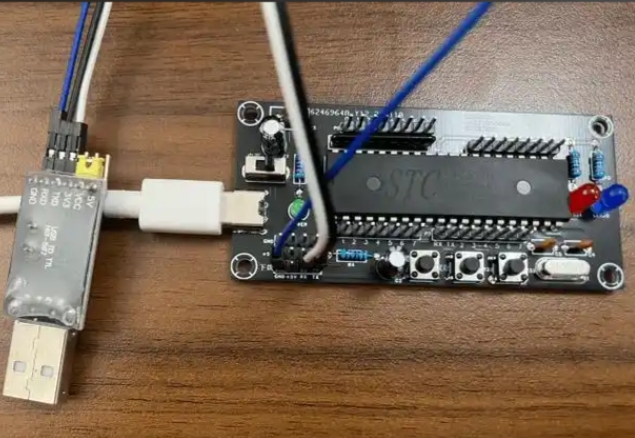

The 8051 microcontroller stands as one of the most enduring and influential architectures in the embedded systems world, having powered countless applications since its introduction by Intel in 1980. At the heart of every 8051-based system lies a critical component that determines its performance, power consumption, and timing accuracy: the clock system. The 8051 MCU clock program represents the fundamental software-hardware interface that controls how instructions are executed, peripherals are synchronized, and power is managed throughout the system. Understanding and properly configuring the clock system is not merely an academic exercise—it’s an essential skill that separates novice embedded developers from seasoned professionals. This comprehensive guide will explore the intricacies of 8051 clock programming, from basic oscillator principles to advanced power management techniques, providing you with the knowledge needed to optimize your embedded designs for any application scenario.

The Foundation of 8051 Clock Systems

Understanding the Clock Architecture

The 8051 microcontroller’s operation is fundamentally governed by its clock signal, which serves as the heartbeat of the entire system. This clock signal is generated by an external oscillator circuit typically composed of a crystal or ceramic resonator connected between pins XTAL1 and XTAL2, along with appropriate loading capacitors. The external crystal frequency directly determines the machine cycle frequency, which is the basic timing unit for instruction execution. It’s crucial to recognize that most 8051 variants divide the oscillator frequency by 12 to generate the machine cycle frequency. This means that a 12 MHz crystal results in a 1 MHz machine cycle rate, where each machine cycle takes 1 microsecond to complete.

Different instructions require different numbers of machine cycles to execute. For example, simple register operations might take just 1-2 machine cycles, while multiplication or division instructions can require 4 machine cycles. This relationship between oscillator frequency and instruction timing forms the basis for calculating precise software delays and establishing accurate communication baud rates. The machine cycle calculation forms the cornerstone of all timing-critical operations in 8051 systems, making it essential knowledge for developers working on applications requiring precise timing, such as real-time control systems, sensor data acquisition, or communication protocols.

Clock Source Options and Selection Criteria

When designing an 8051-based system, engineers have multiple options for generating the clock signal, each with distinct advantages and trade-offs. The most common approach uses a parallel-resonant crystal oscillator, which offers excellent frequency stability and accuracy, typically in the range of ±10 to ±100 ppm. Ceramic resonators provide a lower-cost alternative with slightly reduced accuracy but faster start-up times. For applications where precise timing is less critical, RC oscillators offer the most economical solution, though they suffer from greater frequency variation with temperature and supply voltage changes.

Selecting the appropriate clock source involves balancing multiple factors including cost, accuracy, power consumption, and start-up time. High-frequency crystals (12 MHz to 24 MHz) are ideal for applications requiring high processing throughput or specific standard communication baud rates. Lower-frequency crystals (32.768 kHz) are perfect for battery-powered devices where power conservation is paramount. Modern 8051 derivatives often include internal RC oscillators that eliminate external components, providing adequate accuracy for many non-critical applications while reducing both cost and board space. The internal oscillator option has become increasingly popular with the rise of cost-sensitive, high-volume consumer products where every component counts.

Impact of Clock Frequency on System Performance

The relationship between clock frequency and system performance in 8051 microcontrollers follows a generally linear correlation—higher clock frequencies enable faster instruction execution and greater computational throughput. However, this relationship comes with significant trade-offs that must be carefully considered during system design. Increasing clock frequency directly correlates with higher power consumption, as CMOS circuits dissipate power primarily during switching transitions. This makes frequency selection particularly critical for battery-powered devices where maximizing operational lifetime is essential.

Beyond power considerations, higher clock frequencies can introduce electromagnetic compatibility (EMC) challenges, requiring more careful PCB layout practices and potentially additional shielding or filtering components. Clock frequency also directly affects noise generation, with higher frequencies producing broader spectral emissions that may interfere with sensitive analog circuits or violate regulatory requirements. Furthermore, the maximum usable clock frequency is constrained by the 8051 variant’s specific capabilities—while modern derivatives can operate at frequencies exceeding 100 MHz, traditional 8051 cores typically max out around 40 MHz. Understanding these performance trade-offs enables designers to select optimal clock frequencies that balance processing requirements against power budget, EMC compliance, and cost constraints.

Programming the 8051 Clock System

Basic Clock Configuration Techniques

Configuring the 8051 clock system begins with understanding how to generate precise timing loops in software, which form the basis for creating delays, scheduling tasks, and implementing time-based functions. The most fundamental approach uses carefully crafted software loops that consume known numbers of machine cycles. NOP (No Operation) instructions provide single-cycle delays that can be combined in sequences to create precise timing intervals. For example, a simple 1 ms delay routine for a 12 MHz crystal might combine specific numbers of NOP instructions with loop structures that consume predictable cycle counts.

More sophisticated timing can be achieved using the 8051’s built-in timers, which are themselves clocked by divisions of the main oscillator frequency. Timer 0 and Timer 1 can be configured in various modes to generate precise intervals without continuous CPU intervention. In Mode 1 (16-bit timer mode), developers load specific values into the timer registers (TLx/THx) that determine when overflow occurs and interrupts are generated. Timer reload values must be calculated based on the desired interval and oscillator frequency using formulas that account for the machine cycle relationship. For instance, generating a precise 50 ms interrupt with an 11.0592 MHz crystal requires calculating the appropriate 16-bit reload value that will cause overflow after exactly 50,000 machine cycles (since each machine cycle is approximately 1.085 μs).

For beginners working with 8051 clock programming, platforms like ICGOODFIND offer valuable resources including code examples, oscillator calculation tools, and community support that can significantly accelerate the learning process.

Advanced Power Management Through Clock Control

Modern 8051 derivatives incorporate sophisticated power management capabilities that leverage clock control to significantly reduce energy consumption in battery-operated applications. These techniques include clock division, peripheral clock gating, and multiple idle/sleep modes that strategically disable portions of the clock distribution network. Implementing idle mode halts the CPU while maintaining peripheral operation, allowing the microcontroller to quickly resume full operation when interrupts occur from active peripherals like timers, serial ports, or external signals.

More aggressive power savings can be achieved through power-down mode, which stops the oscillator entirely, reducing current consumption to microamp levels but requiring a full reset to resume operation. Some advanced 8051 variants feature programmable clock dividers that allow dynamic adjustment of the core frequency based on processing requirements—running at full speed during computationally intensive tasks then scaling back during periods of lower activity. Dynamic frequency scaling represents one of the most effective techniques for balancing performance and power consumption in variable-workload applications.

Proper implementation of these power management strategies requires careful consideration of application requirements—specifically which peripherals must remain active during low-power states and what wake-up sources should trigger returns to normal operation. Developers must also account for oscillator start-up times when transitioning from power-down modes, as crystal oscillators can require milliseconds to stabilize while ceramic resonators and RC oscillators typically start much faster.

Baud Rate Generation for Serial Communication

One of the most common applications of precise clock programming in 8051 systems involves generating standard baud rates for serial communication protocols like UART. The baud rate generator uses Timer 1 (typically in auto-reload Mode 2) to create precise timing for serial data transmission and reception. The relationship between oscillator frequency and standard baud rates often drives crystal selection, with values like 11.0592 MHz being particularly popular because they enable generation of standard baud rates (9600, 19200, etc.) with minimal error.

The baud rate calculation formula derives from the timer overflow rate in Mode 2 configuration: Baud Rate = (2^SMOD × Oscillator Frequency) / (32 × 12 × [256 - TH1]). The SMOD bit in the PCON register doubles the baud rate when set, providing additional flexibility. Due to the integer nature of timer reload values, some oscillator frequencies result in significant baud rate errors that can cause communication failures—especially at higher speeds or with longer data frames. Minimizing baud rate error requires careful oscillator frequency selection or using enhanced 8051 variants with independent baud rate generators that offer greater flexibility.

For systems requiring multiple serial channels or non-standard baud rates, some modern 8051 derivatives include dedicated baud rate generator hardware that operates independently from the timers, providing more accurate baud rates across a wider range of oscillator frequencies. Understanding these alternatives becomes crucial when designing systems with strict communication reliability requirements or when constrained to specific crystal frequencies by other system considerations.

Optimizing Clock Configuration for Specific Applications

Real-Time Systems and Timing-Critical Applications

In real-time systems where deterministic response times are essential, clock configuration moves beyond convenience to become a critical design parameter. These applications require meticulous attention to interrupt latency, task scheduling precision, and worst-case execution time analysis—all fundamentally tied to clock configuration. Systematic interrupt latency analysis must account for both hardware and software response times, including the number of machine cycles required to recognize interrupts, complete current instructions, push context to the stack, and jump to interrupt service routines.

For hard real-time systems where missing deadlines constitutes system failure, developers often employ deterministic coding practices that avoid variable-time constructs like loops with data-dependent iteration counts or conditional branches with different path lengths. Instead, they implement fixed-duration routines using precisely timed instruction sequences that maintain consistent execution times regardless of data values or system state. Worst-case execution time analysis forms the foundation for reliable real-time system design, ensuring that even under worst-case conditions, all critical tasks complete within their allocated time windows.

Clock configuration in these demanding environments often involves selecting frequencies that provide adequate processing headroom while avoiding unnecessarily high speeds that would increase power consumption and electromagnetic emissions without tangible benefits. Some safety-critical systems implement heartbeat monitors or windowed watchdogs that verify proper system operation within precisely defined time windows—features that themselves depend on accurate clock configuration.

Low-Power Design Strategies

Battery-powered applications demand particularly careful clock configuration to maximize operational lifetime while maintaining necessary functionality. Effective low-power design employs a multi-faceted approach that combines appropriate clock source selection with dynamic power management strategies tailored to application-specific workload patterns. Selecting lower-frequency crystals significantly reduces dynamic power consumption since CMOS power dissipation is proportional to switching frequency—a relationship expressed by the formula P = C × V² × f, where C represents switched capacitance, V is supply voltage, and f is switching frequency.

Beyond fundamental frequency selection, advanced low-power techniques include strategically transitioning between operational modes based on processing demands. For example, a data logger might operate at full speed during sensor measurement and data storage operations then immediately return to idle or power-down mode during intervals between measurements. Peripheral clock gating selectively disables clocks to unused modules—a feature available in many modern 8051 variants that prevents unnecessary power dissipation in inactive peripherals.

The most sophisticated low-power designs employ adaptive clock scaling that dynamically adjusts operating frequency based on real-time processing requirements—similar to techniques used in modern processors but implemented at a scale appropriate for microcontroller applications. These systems might monitor queue depths, processing deadlines, or external event rates to determine the minimum sufficient operating frequency at any given moment. Combined with selective peripheral activation and optimized voltage regulation, these strategies can extend battery life by orders of magnitude compared to continuously running at maximum frequency.

Troubleshooting Common Clock-Related Issues

Even experienced embedded developers encounter clock-related problems during system development—issues that often manifest as erratic timing, communication errors, or unexpected system resets. Effective debugging requires systematic approaches to identify whether problems originate in hardware oscillator circuits or software configuration. Oscillator start-up problems represent one of the most frequent issues, particularly with high-frequency crystals that may fail to oscillate due to insufficient gain,mismatched load capacitors,inadequate PCB layout,or excessive stray capacitance.

Software-related timing issues often stem from incorrect calculations of timer reload values or misunderstanding of the relationship between oscillator frequency and machine cycles.Baud rate inaccuracies represent another common category of problems,caused by timer reload values that produce frequencies outside acceptable tolerances for reliable serial communication.Methodical signal measurement using oscilloscopes or logic analyzers provides definitive verification of both oscillator operation and derived timing signals,making these instruments indispensable for debugging stubborn clock-related problems.

Modern development tools including simulators and real-time trace debuggers can significantly accelerate identification of timing issues by allowing developers to observe internal timer states,buffer contents,and program flow alongside precise timing information.For systems experiencing electromagnetic compatibility problems related to clock signals,solutions often include adding series termination resistors reducing slew rates through software configuration when available or implementing spread-spectrum clocking techniques that distribute electromagnetic emissions across broader frequency ranges.

Conclusion

The 8051 MCU clock program encompasses far more than simply initializing timers—it represents a fundamental aspect of system design that influences performance,power efficiency,cost,and reliability across virtually all application domains.Mastering clock configuration requires understanding both hardware oscillator fundamentals and software programming techniques while maintaining awareness of their intricate relationships.From basic delay routines to sophisticated power management strategies,the principles discussed in this guide provide a comprehensive foundation for optimizing 8051-based systems for diverse requirements.

As microcontroller technology continues evolving,many modern 8051 derivatives offer enhanced clock systems featuring multiple independent clock domains,finer-grained peripheral gating,and more flexible distribution networks.Yet despite these advancements,the core principles of timing calculation,machine cycle relationships,and power-frequency trade-offs remain consistent across generations.The resources available through platforms like ICGOODFIND continue providing valuable support for developers navigating these complexities.Whether you’re designing battery-powered IoT devices industrial control systems or consumer electronics,a thorough understanding of 8051 clock programming remains an indispensable skill in the embedded developer’s toolkit—one that directly translates into better performing more reliable,and more efficient products.