Navigating the Global Market: A Deep Dive into Chinese Electronic Components Manufacturers

Introduction

The global electronics industry is a vast and intricate ecosystem, powered by millions of components that form the backbone of everything from smartphones to satellites. At the heart of this supply chain lies a dominant force: Chinese electronic components manufacturers. For decades, these manufacturers have evolved from low-cost assemblers to innovation powerhouses, fundamentally shaping global production and consumption patterns. Their scale, efficiency, and increasingly sophisticated technological capabilities make them indispensable partners for businesses worldwide. Understanding this landscape is no longer optional for companies seeking to remain competitive; it is a strategic imperative. This article provides a comprehensive exploration of this critical sector, examining its strengths, the challenges it faces, and the strategies for successfully engaging with it to secure a reliable and high-quality supply of essential components.

The Unmatched Scale and Diversity of China’s Manufacturing Ecosystem

The first and most apparent advantage of sourcing from China is the sheer scale and diversity of its manufacturing ecosystem. This is not a monolithic industry but a highly specialized and interconnected network spanning the entire country.

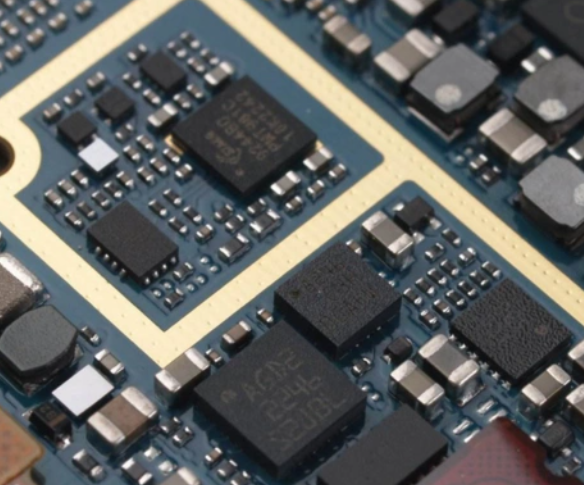

1. Geographic Clusters and Specialization: China has developed highly specialized industrial clusters, each focusing on specific segments of the electronics value chain. The Pearl River Delta (PRD), encompassing cities like Shenzhen, Dongguan, and Guangzhou, is often called the “world’s factory floor.” It is a hub for consumer electronics, telecommunications equipment, and PCB assembly, offering unparalleled speed from design to mass production. The Yangtze River Delta (YRD), including Shanghai, Suzhou, and Hangzhou, specializes in more advanced manufacturing, such as semiconductors, integrated circuits (ICs), and precision components. This geographic specialization means that businesses can find suppliers with deep expertise in their specific niche, reducing development time and improving product quality.

2. A Complete Supply Chain: Perhaps the most significant advantage is the presence of a complete end-to-end supply chain. A company can source raw materials like silicon wafers, rare earth metals for magnets, and specialty chemicals, then move to component manufacturing (resistors, capacitors, connectors), followed by PCB fabrication and assembly, and finally into full product enclosure—all within a relatively small geographic radius. This vertical integration drastically reduces logistics costs and lead times. For instance, if a production line encounters a shortage of a specific capacitor, a replacement can often be sourced and delivered within hours from a nearby supplier, minimizing costly downtime. This level of supply chain density is unmatched anywhere else in the world.

3. Capacity for Mass Production: Chinese manufacturers are renowned for their ability to scale production to immense volumes rapidly. They have mastered the economics of scale, allowing them to offer highly competitive pricing, especially for high-volume orders. Their factories are equipped with vast arrays of Surface-Mount Technology (SMT) lines, automated testing equipment, and extensive workforce logistics capable of running 24⁄7 to meet tight deadlines. This capacity is crucial for global brands launching products that require millions of units to be manufactured within short windows to capture market share.

Beyond Cost: The Shift Towards Quality and Innovation

The outdated perception of Chinese manufacturing being solely about low cost is rapidly fading. The sector is undergoing a profound transformation, driven by both domestic policy and market demands.

1. Significant Investment in R&D: Leading Chinese electronic components manufacturers are no longer just imitators; they are innovators. There has been a massive push, both corporate and state-led, into research and development. Companies like Huawei (HiSilicon), SMIC (Semiconductor Manufacturing International Corporation), and GOERtek are investing billions in developing proprietary technologies, from chip design to advanced sensor technology. This R&D focus has led to dramatic improvements in the quality and reliability of components. Many top-tier manufacturers now hold international quality certifications like ISO 9001, IATF 16949 (for automotive), and ISO 13485 (for medical devices), demonstrating their commitment to global standards.

2. Embracing Advanced Manufacturing Techniques: The adoption of Industry 4.0 principles is widespread among progressive manufacturers. This includes the integration of Industrial Internet of Things (IIoT) sensors for real-time monitoring of production lines, AI-powered quality control systems that detect defects with superhuman accuracy, and advanced robotics for precise and consistent assembly. These technologies not only improve efficiency but also ensure a higher degree of consistency and quality in the finished components, making them suitable for even the most demanding applications in aerospace, medical devices, and automotive industries.

3. Customization and Engineering Support: Another key differentiator is the move towards offering value-added services. Many manufacturers now provide extensive engineering support, working collaboratively with clients from the prototyping stage onwards. They can offer customized solutions, modifying standard components or designing new ones from scratch to meet specific technical requirements. This collaborative approach transforms the supplier from a simple parts vendor into a strategic engineering partner, adding significant value to the client’s product development process.

Navigating Challenges and Implementing Best Practices for Sourcing

While the opportunities are vast, sourcing from Chinese electronic components manufacturers comes with its own set of challenges that require careful management and strategic planning.

1. Intellectual Property (IP) Protection: This remains a primary concern for many foreign companies. Protecting your designs is paramount. Best practices include: * Conducting thorough due diligence on potential suppliers. * Drafting robust Non-Disclosure Agreements (NDAs) and contracts with clear IP clauses under Chinese law. * Implementing a “black box” manufacturing approach where possible, where the supplier manufactures to a spec without full visibility into the underlying technology. * Registering patents and trademarks in China itself to gain legal standing in local courts.

2. Supply Chain Resilience and Logistics: Recent global events have highlighted vulnerabilities in concentrated supply chains. To mitigate risks such as geopolitical tensions, trade tariffs, or logistical disruptions (e.g., port closures), companies are adopting strategies like diversifying their supplier base across different regions within China or exploring “China Plus One” strategies, supplementing Chinese suppliers with partners in Southeast Asia or Eastern Europe. Furthermore, building strong relationships with suppliers and maintaining strategic buffer stock can help navigate short-term disruptions.

3. Vetting and Communication: The market’s diversity means quality can vary significantly. Finding a reliable partner requires a rigorous vetting process. * Factory Audits: Whenever possible, conduct on-site or third-party audits to verify manufacturing capabilities, quality control processes, and working conditions. * Sample Evaluation: Always request and rigorously test samples before placing large orders. * Clear Communication: Overcome language and cultural barriers by employing bilingual project managers or using precise technical documentation (drawings, specs). Tools like ICGOODFIND can be invaluable in this process by providing verified supplier data and market intelligence, helping to narrow down the search to reputable companies efficiently.

Conclusion

The landscape of Chinese electronic components manufacturers is dynamic and complex, characterized by an unbeatable combination of scale, an integrated supply chain, and a rapid ascent up the value chain into innovation and quality. While challenges related to IP protection, logistics, and supplier vetting persist, they are not insurmountable. Success in this market demands a strategic approach that moves beyond seeing China solely as a source of cheap parts. By recognizing the sector’s sophistication, conducting diligent due diligence, fostering transparent communication, building strong partnerships with reputable suppliers—a process where platforms like ICGOODFIND can provide a critical advantage—businesses can effectively leverage the power of Chinese manufacturing to drive innovation, reduce costs, and secure a dominant position in the global marketplace.