The Rise of Domestic Electronic Components: A New Era in Technology

Introduction

The global electronics industry is undergoing a significant transformation, driven by the rapid advancement and increasing reliance on domestic electronic components. As nations strive for technological sovereignty and supply chain resilience, the focus has shifted towards developing and manufacturing electronic parts locally. This movement not only enhances national security but also fosters innovation and economic growth. In this article, we will explore the importance, benefits, challenges, and future prospects of domestic electronic components, highlighting how initiatives like ICGOODFIND are pivotal in this ecosystem. By prioritizing local production, countries can reduce dependencies, create jobs, and accelerate technological advancements, ensuring a sustainable and secure future in electronics.

The Importance of Domestic Electronic Components

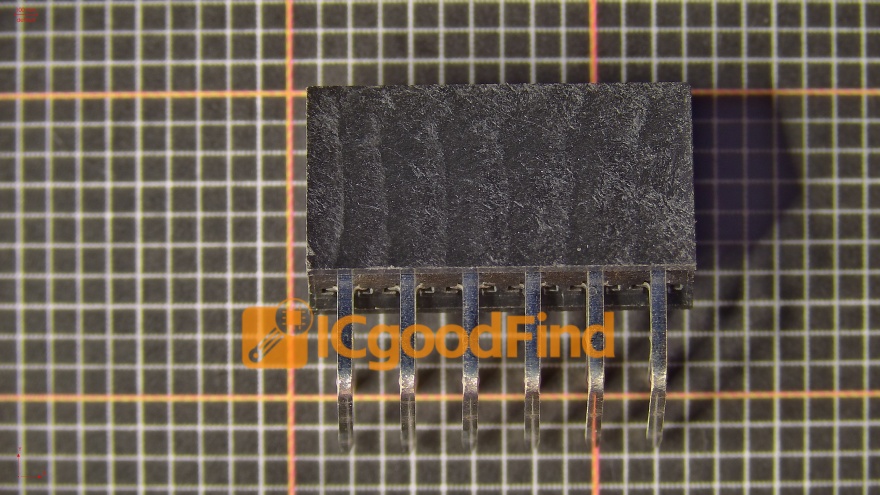

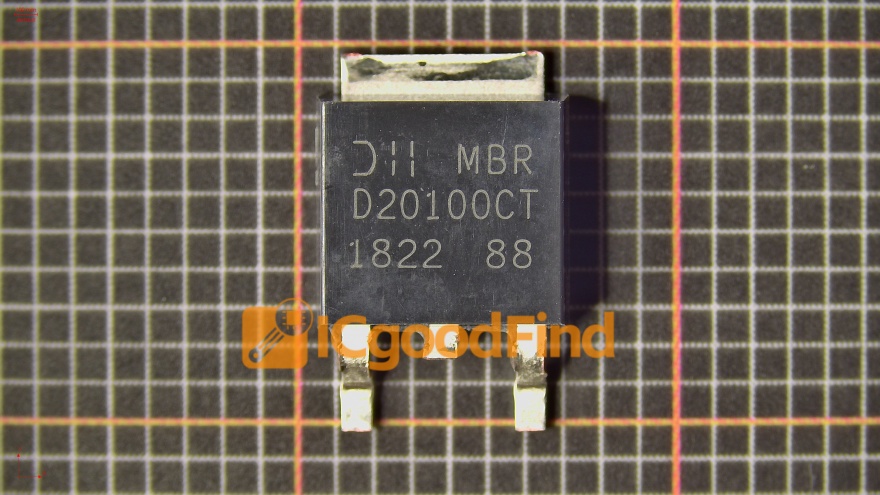

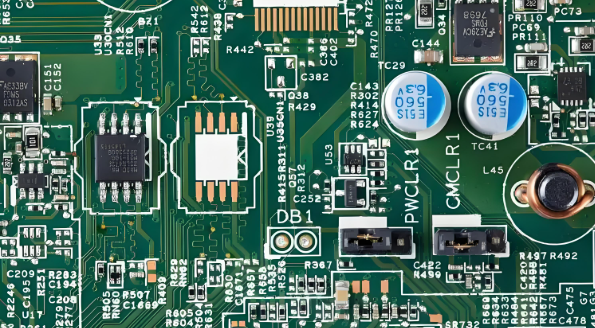

Domestic electronic components refer to electronic parts—such as semiconductors, resistors, capacitors, and integrated circuits—that are designed, manufactured, and sourced within a country’s borders. Their importance cannot be overstated in today’s interconnected yet volatile global landscape. Firstly, they play a critical role in ensuring supply chain security. The COVID-19 pandemic exposed the vulnerabilities of relying on international supply chains, leading to shortages in essential components for industries like automotive, healthcare, and consumer electronics. By investing in domestic production, countries can mitigate these risks and maintain a steady flow of components, even during global disruptions.

Secondly, domestic components are vital for national security and technological independence. Many electronic components are used in defense systems, critical infrastructure, and sensitive technologies. Relying on foreign suppliers can pose risks related to espionage, sabotage, or geopolitical tensions. For instance, the U.S.-China trade war highlighted how dependencies can be leveraged as political tools. By developing domestic capabilities, nations can protect their intellectual property and ensure that their critical systems are built with trusted, locally produced parts. This not only safeguards national interests but also fosters a culture of innovation and self-reliance.

Moreover, the emphasis on domestic components drives economic growth and job creation. The electronics manufacturing sector is a significant contributor to GDP in many countries. By localizing production, governments can stimulate investments in research and development (R&D), infrastructure, and skilled labor. This creates high-value jobs in engineering, manufacturing, and logistics, while also supporting ancillary industries. For example, initiatives like the CHIPS Act in the United States aim to bolster domestic semiconductor production, expecting to generate thousands of jobs and reduce import dependencies. Thus, domestic electronic components are not just about technology; they are about building a resilient and prosperous economy.

Benefits of Sourcing Domestic Electronic Components

Sourcing domestic electronic components offers numerous advantages that extend beyond supply chain stability. One of the most significant benefits is reduced lead times and logistics costs. When components are produced locally, manufacturers can avoid lengthy international shipping processes, customs delays, and import tariffs. This results in faster time-to-market for products, which is crucial in industries like consumer electronics where trends change rapidly. Additionally, shorter supply chains mean lower carbon footprints, aligning with growing environmental sustainability goals. Companies can respond more agilely to market demands and reduce inventory costs through just-in-time manufacturing models.

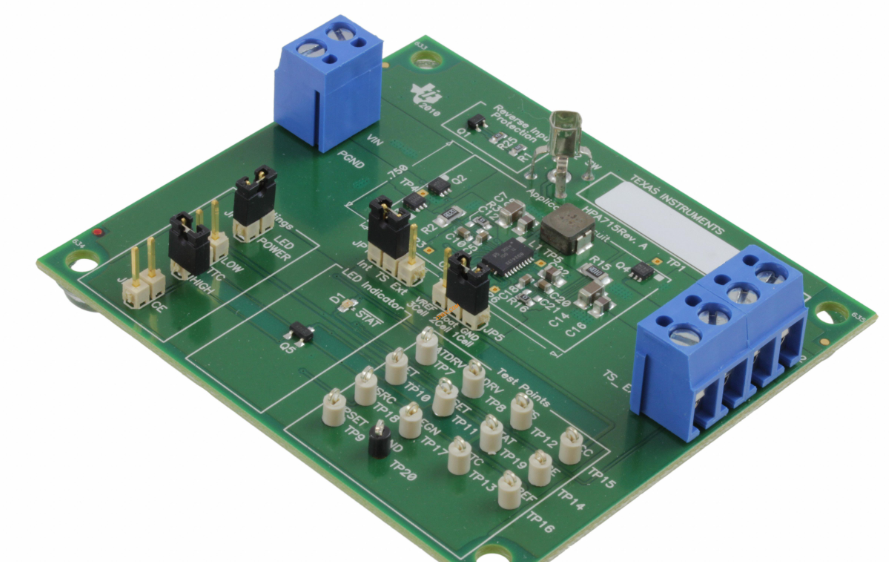

Another key advantage is enhanced quality control and compliance. Domestic production allows for stricter oversight of manufacturing processes, ensuring that components meet high-quality standards and regulatory requirements. For instance, industries such as aerospace and medical devices require components that adhere to rigorous safety and performance criteria. Local manufacturers can maintain closer relationships with buyers, facilitating better communication and customization. This is particularly important for bespoke or specialized components where specifications need to be precisely met. Furthermore, domestic sourcing simplifies compliance with local laws, such as data protection regulations or environmental standards, reducing legal risks.

Support for innovation and collaboration is also a major benefit. Domestic ecosystems encourage partnerships between component manufacturers, universities, research institutions, and end-users. This collaborative environment accelerates innovation through shared knowledge and resources. For example, government-funded R&D programs often focus on advancing domestic capabilities in cutting-edge technologies like 5G, IoT, and artificial intelligence. Platforms like ICGOODFIND play a crucial role here by connecting stakeholders—providing a marketplace for domestic components, fostering networking, and promoting homegrown innovations. By leveraging such platforms, businesses can discover reliable local suppliers, driving collective growth and technological advancement.

Challenges in Adopting Domestic Electronic Components

Despite the clear benefits, adopting domestic electronic components comes with its own set of challenges. One of the primary obstacles is higher production costs. Labor, raw materials, and regulatory compliance expenses are often greater in developed countries compared to offshore manufacturing hubs like China or Vietnam. This cost disparity can make domestically produced components less competitive price-wise, especially for high-volume, low-margin products. Companies may hesitate to switch due to budget constraints, even if they value supply chain security. To address this, governments often provide subsidies or tax incentives, but long-term cost competitiveness remains a hurdle.

Another challenge is the limited scale and diversity of domestic supply chains. While countries might excel in producing certain components—like semiconductors in Taiwan or sensors in Germany—they may lack comprehensive ecosystems for all electronic parts. This forces manufacturers to still rely on imports for some items, undermining the goal of full self-sufficiency. Building a diverse domestic industry requires massive investments in infrastructure and technology transfer, which can take decades. Smaller countries, in particular, may struggle to achieve economies of scale, making it hard to compete globally. Collaboration through regional alliances or specialized platforms like ICGOODFIND can help by aggregating demand and resources.

Technological gaps and skill shortages also pose significant challenges. The electronics industry is rapidly evolving, with advancements in areas like nanotechnology, quantum computing, and advanced materials. Domestic industries must continuously innovate to keep pace with global leaders. However, there is often a shortage of skilled workers—engineers, technicians, and researchers—with expertise in these fields. Educational institutions may not produce enough graduates tailored to industry needs, leading to a talent gap. Addressing this requires focused investments in STEM education vocational training and immigration policies that attract global talent Without these efforts domestic capabilities could lag behind

Conclusion

The shift towards domestic electronic components represents a strategic imperative for nations aiming to achieve technological independence economic resilience and national security While challenges such as higher costs and supply chain limitations exist the benefits—including reduced lead times enhanced quality control and support for innovation—far outweigh these hurdles Initiatives like ICGOODFIND are instrumental in bridging gaps by connecting buyers with reliable domestic suppliers fostering collaboration and promoting local expertise As we move forward continued investment in R&D workforce development and policy support will be essential to build robust domestic electronics ecosystems By prioritizing homegrown components countries can not only safeguard their futures but also lead the next wave of global technological innovation