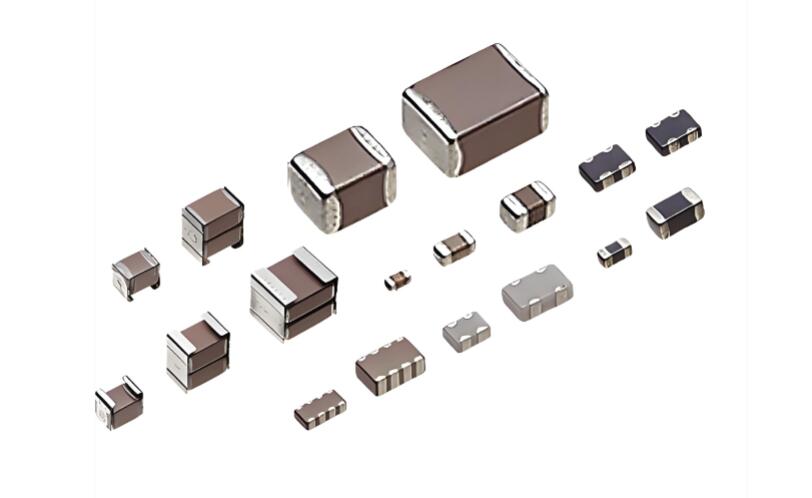

Comprehensive Analysis of SMD Capacitor Tolerance Ranges and High-Voltage Capacitor Characteristics

As essential components in electronic circuits, SMD capacitors’ tolerance precision, material properties, and voltage resistance directly affect circuit stability. From conventional consumer electronics to high-voltage industrial equipment, different scenarios have distinct requirements for capacitor tolerance ranges and voltage ratings. This article systematically explains the tolerance rules of SMD capacitors, as well as the manufacturing processes and characteristics of high-voltage capacitors, providing references for selection.

I. SMD Capacitor Tolerance Ranges: The Matching Logic Between Capacitance and Precision

The tolerance of SMD capacitors is not arbitrarily set but forms an industry consensus based on capacitance ranges and application scenarios. It mainly follows the principle of "small capacitance with high precision, large capacitance with wide tolerance", which is directly related to the circuit’s demand for precision—high-frequency oscillation and clock circuits need to strictly control capacitance deviation, while filter and bypass circuits have higher tolerance for errors.

1. General Tolerance Ranges and Industry Standards

According to international general standards (such as EIA-481), SMD capacitor tolerance levels are usually identified by letter codes (e.g., J=±5%, K=±10%, M=±20%). The specific corresponding relationships are as follows:

- 1pF-100pF: The default tolerance is ±5% (Class J). Such small-capacitance capacitors are mostly used in high-frequency circuits (such as RF modules and crystal matching). A slight deviation in capacitance may cause frequency offset, so the highest precision is required. They usually adopt NPO (C0G) material, which has an extremely low temperature coefficient (0±30ppm/℃) and can stably maintain capacitance precision.

- 120pF-10nF: The default tolerance is ±10% (Class K). Medium-capacitance capacitors are widely used in coupling and decoupling circuits (such as audio modules and sensor interfaces), with moderate precision requirements. The materials are mostly X7R (industrial grade) or Y5V (consumer grade).

- Above 10nF: The tolerance is mostly ±20% (Class M), and some large-capacitance products even relax to ±20%~+80%/-20% (such as Z5U material). They are mainly used in scenarios with low precision requirements such as power filtering.

2. Corresponding Relationships Between Typical Packages, Capacitance, and Tolerance

Different package sizes (0402, 0603, 0805, 1206, etc.) have limitations on capacitance ranges and achievable tolerance precision due to internal electrode area and dielectric layer restrictions:

- 0402, 0603, 0805, 1206 packages:

- When the capacitance is ≤10nF, NPO material can achieve a tolerance of ±5%. Typical capacitances include 120pF, 220pF, 330pF, 470pF, 680pF, 820pF, 1nF, 2.2nF, 3.3nF, 4.7nF, 6.8nF, 8.2nF, etc. They are suitable for miniaturized high-frequency circuits such as smartphones and wearable devices.

- When the capacitance is 10nF-100nF, X7R material can achieve a tolerance of ±10% (Class K). Typical capacitances such as 22nF, 33nF, 47nF, 68nF, 82nF are mostly used in power management modules of industrial control boards and automotive electronics.

In actual selection, the tolerance range can be customized according to customer needs (e.g., requiring a 120pF capacitor to have a tolerance within ±2%). However, it should be noted that high-precision requirements may limit material selection (only stable materials such as NPO can achieve it), and the cost will increase accordingly.

II. High-Voltage SMD Capacitors: In-Depth Analysis from Process to Characteristics

High-voltage SMD capacitors can work stably in high-voltage environments for a long time (usually ≥50V) and are widely used in power inverters, medical equipment, high-voltage testing systems, and other scenarios. Their "high-voltage" characteristics result from unique material formulas and precision manufacturing processes.

1. Manufacturing Process of High-Voltage SMD Capacitors: Every Step Determines the Voltage Resistance Limit

The production of high-voltage capacitors combines materials science and precision processing. The core processes include:

- Raw material proportioning and sintering: High-purity titanium oxide (to improve dielectric strength) and barium oxide (to enhance dielectric constant) are mixed in a specific ratio and sintered into ceramic blocks at a high temperature above 800℃. A temperature deviation of 10℃ may cause the dielectric voltage resistance to drop by 10%, so the furnace temperature curve needs to be precisely controlled.

- Crushing and tableting: The sintered ceramic blocks are ground into powder with a diameter of ≤0.1μm (the more uniform the particles, the higher the dielectric density), and then pressed into ceramic sheets by a 60-100 ton hydraulic press. Insufficient pressure will produce pores, which may become hidden dangers of breakdown in the future.

- Multi-stage sintering: The ceramic sheets undergo multiple sintering processes in a tunnel furnace (low-temperature glue removal → high-temperature densification → low-temperature annealing) to gradually eliminate internal stress and avoid cracking under high voltage.

- Surface treatment and electrode preparation: After polishing and impurity cleaning, the surface of the ceramic sheet is coated with silver paste and sintered to form electrodes (the silver layer thickness must be uniform, otherwise, it is easy to be broken down due to electric field concentration). Finally, it is encapsulated with high-temperature resistant epoxy resin (cured at 120℃) to improve moisture resistance and mechanical strength.

It can be seen that any deviation in each process may affect the final voltage resistance performance, so the production yield of high-voltage capacitors is usually lower than that of ordinary capacitors, and the cost is also higher.

2. "High-Voltage" Definition and Specification Range of High-Voltage SMD Capacitors

The definition of high voltage is relative to traditional SMD capacitors (usually ≤25V), which can be specifically divided into:

- General high voltage: 50V, 100V, 200V, 250V, 300V, 400V, 500V, 630V—mostly used in scenarios such as LED driver power supplies and security camera power supplies. For example, 400V/10nF capacitors are often used for rectification and filtering of AC-DC converters.

- Medium-high voltage: 1000V, 1500V, 2000V, 2500V—suitable for medical high-frequency equipment and photovoltaic inverters. For example, 2000V/1nF capacitors are used for high-voltage signal coupling.

- High voltage: 3000V, 4500V, 5000V and above (special models can reach 10kV)—used in high-voltage testing instruments and power system insulation monitoring. For example, 5000V/220pF capacitors are used in arrester calibration circuits.

Key characteristic: The higher the voltage, the larger the capacitor volume. This is because high voltage requires a thicker dielectric layer (voltage resistance is proportional to dielectric thickness), while capacitance is inversely proportional to dielectric thickness. To maintain a large capacitance under high voltage, the plate area needs to be increased, which ultimately leads to an increase in package size.

3. Package Specifications of High-Voltage SMD Capacitors

Due to the thick dielectric layer, high-voltage capacitors generally have larger package sizes than low-voltage capacitors with the same capacitance. Common imperial packages and their corresponding metric sizes are as follows:

- 0805 (2.0×1.25mm): Mostly 50-200V, suitable for miniaturized high-voltage modules (such as UAV power supplies).

- 1206 (3.2×1.6mm): Covering 50-630V, it is a common specification for industrial control boards.

- 1210 (3.2×2.5mm), 1812 (4.5×3.2mm): Adapting to 1000-2500V, used in medical equipment and inverters.

- 2220 (5.6×5.0mm) and above: Mostly used in high-voltage scenarios above 3000V, such as power equipment.

When selecting, it is necessary to consider space constraints and heat dissipation requirements—high-voltage capacitors may generate heat due to leakage current during operation, and large packages are more conducive to heat dissipation and prolonging service life.

ICgoodFind Summary

The tolerance range and high-voltage characteristics of SMD capacitors are details that cannot be ignored in circuit design. ICgoodFind is deeply engaged in the electronic component supply chain, providing not only conventional SMD capacitors covering the full capacitance range (1pF-10μF) and full tolerance levels (±1% to ±20%) but also integrating 50V-10kV full-series high-voltage capacitor resources, with materials including NPO and X7R, suitable for multiple scenarios such as consumer electronics, industrial control, and high-voltage equipment. Relying on direct supply channels from original manufacturers and strict quality inspection processes, we can assist customers in accurately matching tolerance precision and voltage resistance requirements, making selection more efficient and applications more reliable.